Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

52100, 100Cr6, SUJ2, stainless steel

Бренд

QIBR/OEM/Neutral

Применения

Conveyor systems, agricultural machinery, and textile machinery, etc

Внутренний диаметр (d)

5-50 mm

Наружный диаметр (D)

19-110mm

Вес

0.009-1.2 kg

Упаковка

Standard Export Package

| NO. | Product | Product Number | Базовая динамическая нагрузка | Базовая статическая нагрузка | Отверстие | Вес | Наружный диаметр (D) | Ширина (B) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

135 TN9 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135/P5 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 C3 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 ETN9 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 E-2RS1TN9 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 E-2RS1KTN9 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135/P6 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 1 |

|

135 EKTN9 | 2.51 KN | 0.48 KN | 5 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 TN9 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126/P5 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 C3 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 ETN9 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 E-2RS1KTN9 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126/P6 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 EKTN9 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 2 |

|

126 E-2RS1TN9 | 2.51 KN | 0.48 KN | 6 mm | 0.009 kg | 19 mm | 6 mm |

| 3 |

|

127 TN9 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127/P5 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 C3 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 ETN9 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 E-2RS1KTN9 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 E-2RS1TN9 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127/P6 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 3 |

|

127 EKTN9 | 2.65 KN | 0.56 KN | 7 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 TN9 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108/P5 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 C3 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 ETN9 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 E-2RS1TN9 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 EKTN9 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108 E-2RS1KTN9 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 4 |

|

108/P6 | 2.65 KN | 0.56 KN | 8 mm | 0.014 kg | 22 mm | 7 mm |

| 5 |

|

129 TN9 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129/P5 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 C3 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 ETN9 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 EKTN9 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 E-2RS1TN9 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129 E-2RS1KTN9 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 5 |

|

129/P6 | 3.9 KN | 0.82 KN | 9 mm | 0.022 kg | 26 mm | 8 mm |

| 6 |

|

1200 ETN9 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200/P5 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 C3 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 EKTN9 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 E-2RS1KTN9 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 E-2RS1TN9 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200/P6 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 6 |

|

1200 TN9 | 5.53 KN | 1.18 KN | 10 mm | 0.034 kg | 30 mm | 9 mm |

| 7 |

|

2200 E-2RS1TN9 | 5.53 KN | 1.18 KN | 10 mm | 0.048 kg | 30 mm | 14 mm |

| 8 |

|

2200 ETN9 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200/P5 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 C3 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 EKTN9 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 E-2RS1KTN9 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 E-2RS1TN9 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200/P6 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 8 |

|

2200 TN9 | 8.06 KN | 1.73 KN | 10 mm | 0.047 kg | 30 mm | 14 mm |

| 9 |

|

1201 ETN9 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201/P5 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 C3 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 EKTN9 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 E-2RS1TN9 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 E-2RS1KTN9 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201/P6 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 9 |

|

1201 TN9 | 6.24 KN | 1.43 KN | 12 mm | 0.04 kg | 32 mm | 10 mm |

| 10 |

|

2201 E-2RS1TN9 | 6.24 KN | 1.43 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 ETN9 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201/P5 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 C3 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 EKTN9 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 E-2RS1TN9 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201/P6 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 TN9 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 11 |

|

2201 E-2RS1KTN9 | 8.52 KN | 1.9 KN | 12 mm | 0.053 kg | 32 mm | 14 mm |

| 12 |

|

1301/P5 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 C3 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 EKTN9 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 E-2RS1TN9 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301/P6 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 ETN9 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 TN9 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 12 |

|

1301 E-2RS1KTN9 | 9.36 KN | 2.16 KN | 12 mm | 0.067 kg | 37 mm | 12 mm |

| 13 |

|

2301 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301/P5 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301 C3 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301 ETN9 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301 E-2RS1TN9 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301 EKTN9 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301/P6 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

| 13 |

|

2301 TN9 | 11.7 KN | 2.7 KN | 12 mm | 0.095 kg | 37 mm | 17 mm |

Особенности и преимущества самоустанавливающихся шарикоподшипников QIBR

Самоустанавливающиеся шарикоподшипники QIBR решили множество ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1. Функция автоматического самоустанавливающегося подшипника

Самой главной особенностью самоустанавливающихся шарикоподшипников QIBR является то, что они могут автоматически выравниваться. Поскольку относительное положение дорожек качения внутреннего и наружного колец имеет определенный угол (то есть, дорожка качения наружного кольца сферическая). При относительном смещении вала или посадочного места подшипника контактная поверхность шарика и дорожки качения автоматически регулируется, что обеспечивает стабильное рабочее состояние подшипника и уменьшает износ, вызванный угловой погрешностью.

2. Грузоподъемность

Самоустанавливающиеся шарикоподшипники QIBR обладают относительно высокой грузоподъемностью. Он может выдерживать определенные радиальные и осевые нагрузки.

3. Сильная адаптивность

Самоустанавливающиеся шарикоподшипники QIBR особенно подходят для случаев, когда в процессе установки возникает осевое отклонение, благодаря своим самоустанавливающимся характеристикам. Например, изгиб вала, неправильная установка гнезда подшипника и т.д., эти ситуации могут вызвать угловые отклонения в подшипнике, но самоустанавливающийся шарикоподшипник может эффективно компенсировать эти проблемы и поддерживать бесперебойную работу.

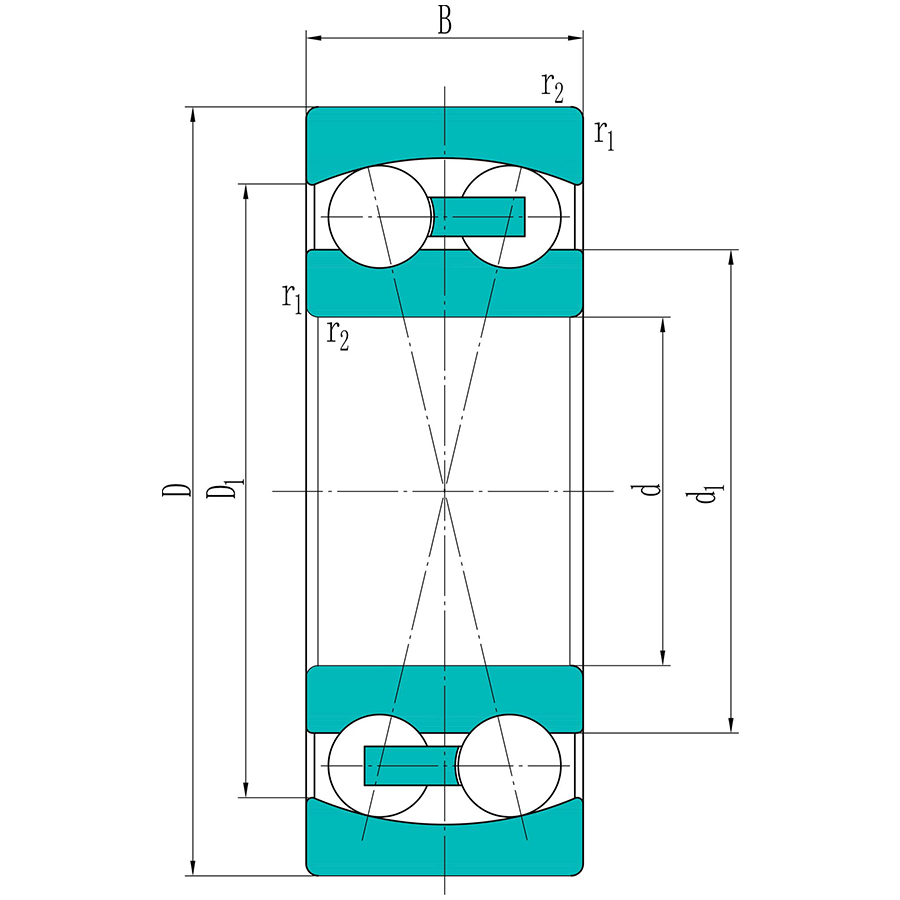

Самоустанавливающиеся шарикоподшипники QIBR имеют двухрядную конструкцию с двумя рядами шариковых сепараторов, которые могут выдерживать большие радиальные нагрузки.

Улучшение характеристик и решения самоустанавливающегося шарикоподшипника QIBR

1. Оптимизация смазки

Выбор подходящего смазочного масла или консистентной смазки, а также соответствующих добавок и смесей для снижения трения и повышения износостойкости. Использование синтетических смазочных материалов или наносмазок может значительно повысить эффективность и срок службы подшипников.

2. Оптимизация дорожек качения

Оптимизация геометрии дорожек качения внутреннего и наружного колец, например, повышение точности дорожек качения, улучшение качества обработки поверхности, снижение трения и уменьшение потерь энергии, что повышает эффективность работы подшипника.

3. Улучшение качества тел качения

Снижение трения и износа за счет улучшения качества поверхности и твердости тел качения. Использование высокоточных тел качения (например, керамики) может значительно улучшить эксплуатационные характеристики подшипника.

4. Оптимизация конструкции сепаратора

Использование более оптимизированной конструкции сепаратора, например, использование термостойких и коррозионностойких материалов и конструкций, для повышения долговечности сепаратора и стабильности подшипника.

Основные области применения самоустанавливающихся шарикоподшипников QIBR

Двигатель и система трансмиссии

В двигателе и трансмиссии автомобиля самоустанавливающийся шарикоподшипник может быть использован для адаптации к несоосности валов, вызванной вибрацией или тепловым расширением двигателя и других деталей.

Вентиляторы, воздуходувки и насосы

Поскольку в этих устройствах часто случаются изгибы валов или ошибки при установке, использование самоустанавливающихся шарикоподшипников позволяет снизить затраты на обслуживание и продлить срок службы оборудования.

Вибрационный грохот

В горнодобывающей промышленности самоустанавливающиеся шарикоподшипники широко используются в таком оборудовании, как вибрационные грохоты. Вибрационные грохоты должны работать в условиях высокой нагрузки и вибрации. Самоустанавливающиеся шарикоподшипники могут эффективно устранить несоосность валов и проблемы смещения, вызванные вибрацией оборудования.

Подшипники для железнодорожного транспорта

В железнодорожном транспорте самоустанавливающиеся шарикоподшипники могут справиться с такими проблемами, как неровности пути и смещение колес, чтобы обеспечить плавность и надежность работы транспортного средства.