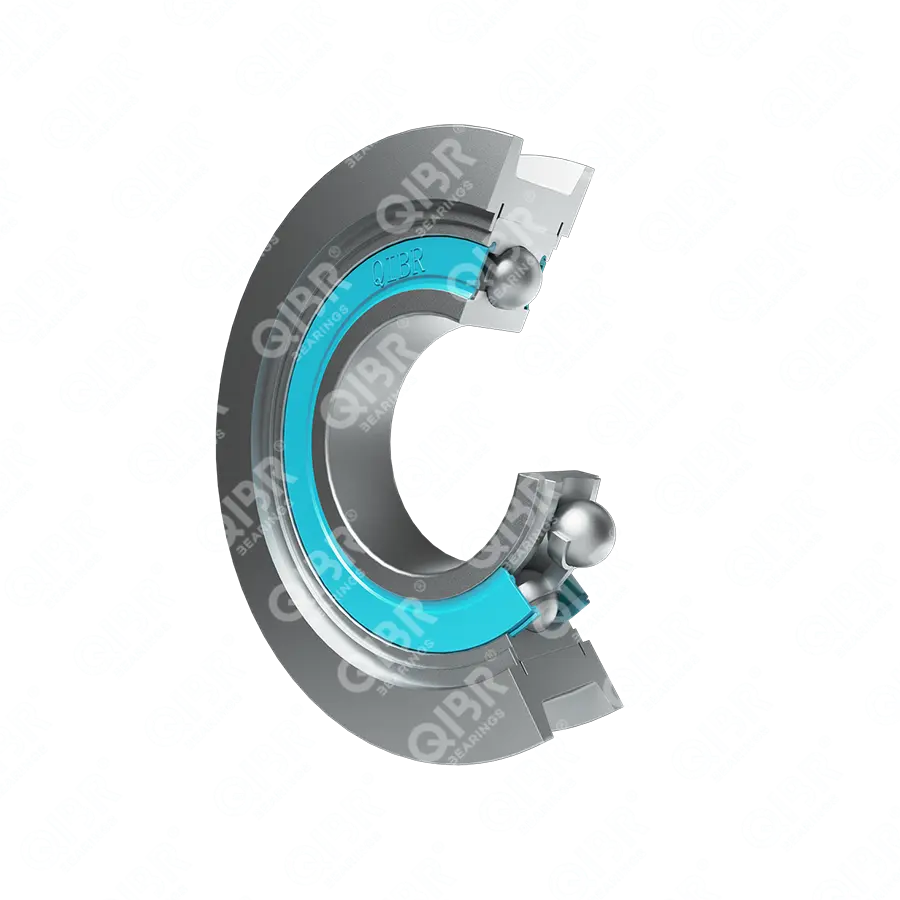

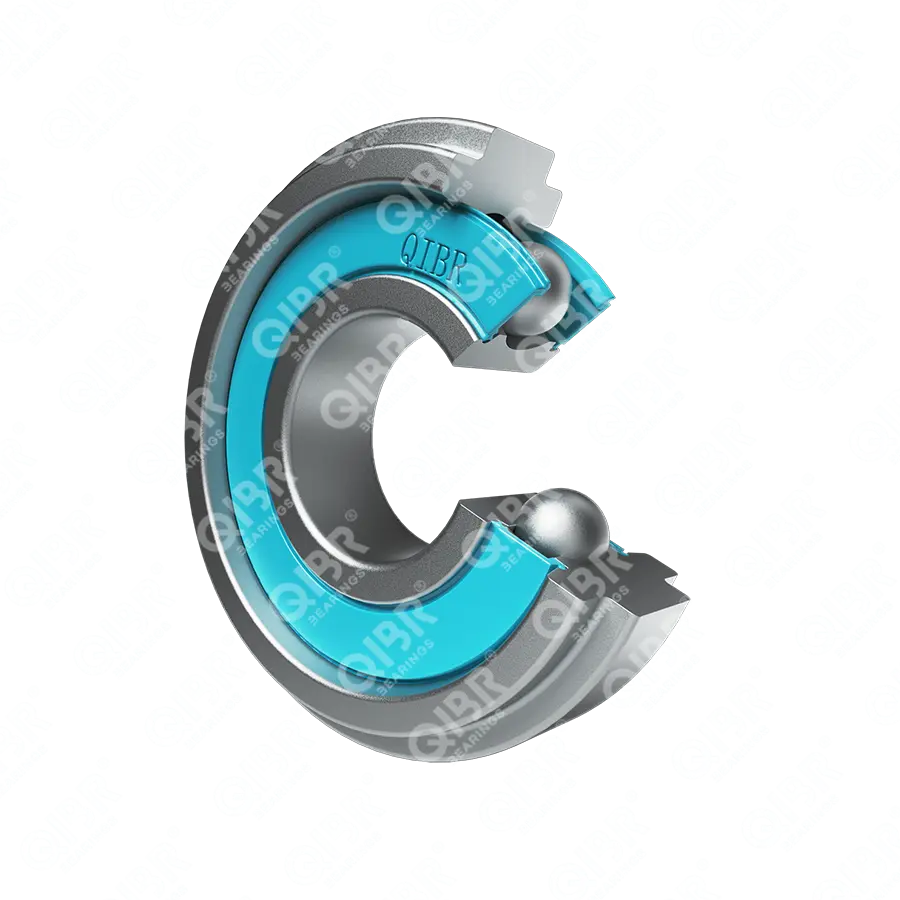

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

GCr15

Внутренний диаметр кольца

1.0000 in.-1.3780 in.

Общая ширина

0.9100 in.-2.6100 in.

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

Применения

Forklift

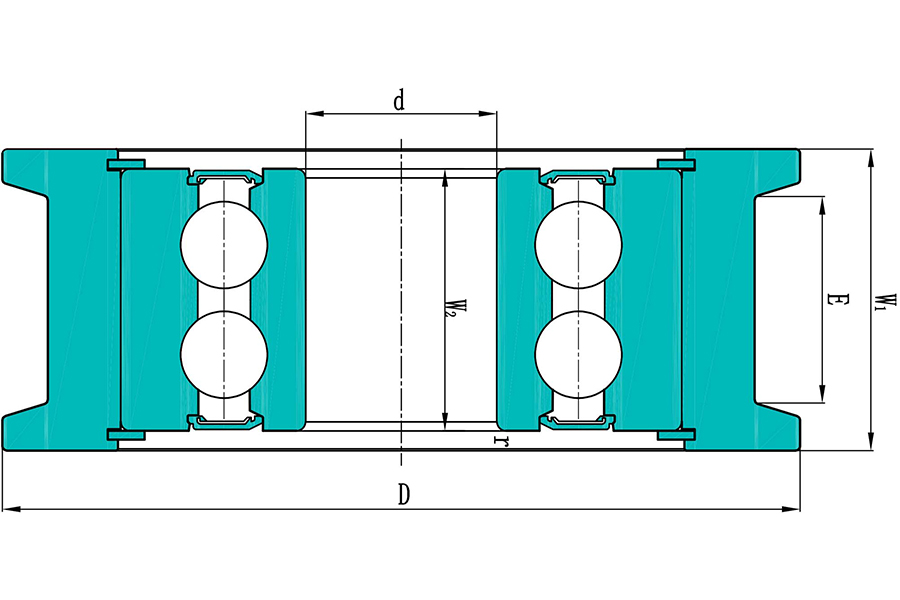

| NO. | Product | Product Number | Отверстие | Округление (r) | Внутреннее кольцо (W2) | Наружный диаметр (D) | Наружное кольцо (W1) |

|---|---|---|---|---|---|---|---|

| 1 |

|

CG-205-RR | 1.0000 inch | 0.0800 inch | 0.6250 inch | 2.5000 inch | 0.9100 inch |

| 2 |

|

CG-307-FFA | 1.3780 inch | 0..0980 inch | 0.8268 inch | 4.6660 inch | 1.1930 inch |

| 3 |

|

CG-308-FF | 1.5748 inch | 0.0600 inch | 0.9055 inch | 4.6460 inch | 1.2600 inch |

| 4 |

|

CG-307-FFB | 1.3780 inch | 0.0600 inch | 0.8268 inch | 4.3750 inch | 1.5000 inch |

| 5 |

|

CG-309-FF | 1.7717 inch | 0.0600 inch | 0.9843 inch | 5.1300 inch | 1.5500 inch |

| 6 |

|

CG-5208-VFF | 1.5748 inch | 0.0400 inch | 1.1925 inch | 3.7600 inch | 1.5000 inch |

| 7 |

|

CG-5208-VFFA | 1.5748 inch | 0.0400 inch | 1.7250 inch | 3.7600 inch | 1.5000 inch |

| 8 |

|

CG-5309-KFF | 1.7717 inch | 0.0400 inch | 2.1770 inch | 4.7360 inch | 2.0190 inch |

| 9 |

|

CG-5309-KFFA | 1.7717 inch | 0.0400 inch | 2.6100 inch | 4.7360 inch | 2.4520 inch |

| 10 |

|

CG-5206-SSB | 0.9843 inch | - | 0.9375 inch | 4.2500 inch | 1.5200 inch |

| 11 |

|

CG-5206-SSE | 0.9843 inch | - | 0.9375 inch | 4.2500 inch | 1.5200 inch |

| 12 |

|

CG-5206-FFB | 1.1811 inch | - | 0.9375 inch | 4.2500 inch | 1.5200 inch |

| 13 |

|

CG-5206-FFE | 1.1811 inch | - | 0.9375 inch | 4.2500 inch | 1.5200 inch |

| 14 |

|

CG-5108-VFF | 1.5748 inch | - | 0.8100 inch | 3.5100 inch | 1.0050 inch |

| 15 |

|

CG-5108-VFFA | 1.5748 inch | - | 0.8100 inch | 5.5100 inch | 1.0050 inch |

| 16 |

|

CG-5207-VFFB | 1.5748 inch | - | 1.1875 inch | 3.7000 inch | 1.3700 inch |

| 17 |

|

CG-5208-VFFH | 1.5748 inch | - | 1.1875 inch | 5.6300 inch | 1.3700 inch |

| 18 |

|

CG-5208-VFFJ | 1.5748 inch | - | 1.1875 inch | 4.7600 inch | 1.3700 inch |

| 19 |

|

CG-5210-VFF | 1.9685 inch | 0.0600 inch | 1.2025 inch | 5.8100 inch | 1.4100 inch |

| 20 |

|

CG-5210-VFFA | 1.9685 inch | 0.0600 inch | 1.2025 inch | 5.0100 inch | 1.4100 inch |

| 21 |

|

CG-5210-VFFE | 1.9685 inch | 0.0600 inch | 1.2025 inch | 6.9100 inch | 1.4100 inch |

| 22 |

|

CG-5210-VFFH | 1.9685 inch | 0.0600 inch | 1.2025 inch | 4.8800 inch | 1.5100 inch |

| 23 |

|

CG-5108-VFFB | 1.5748 inch | - | 0.8100 inch | 3.5100 inch | 1.5100 inch |

| 24 |

|

CG-5207-VFFA | 1.5748 inch | - | 1.2025 inch | 3.7600 inch | 1.8200 inch |

| 25 |

|

CG-5210-VFFB | 1.9685 inch | - | 1.2025 inch | 5.2600 inch | 1.8850 inch |

| 26 |

|

CG-207-FFA | 1.3780 inch | 0.400 inch | 0.6693 inch | 3.1720 inch | 0.4590 inch |

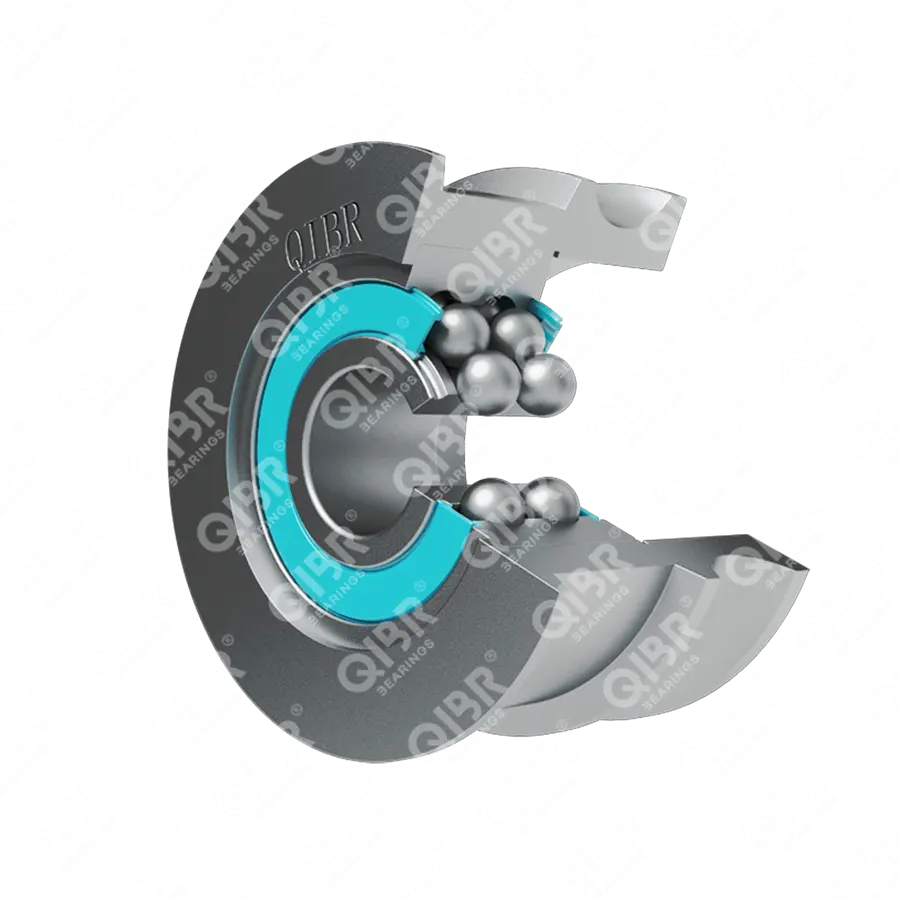

Особенности и преимущества роликовых подшипников направляющих цепей

Роликовые подшипники направляющих цепей решают несколько ключевых проблем в различных областях, в основном отраженных в следующих аспектах:

1. Высокая прочность и износостойкость

Роликовые подшипники цепей вилочных погрузчиков обычно изготавливаются из высокопрочной стали или легированных материалов, что обеспечивает им высокую прочность на сжатие и длительный срок службы.

2. Высокая грузоподъемность

Роликовые подшипники цепей вилочных погрузчиков передают энергию и нагрузку через цепь, поэтому они должны обладать высокой грузоподъемностью. Высококачественные роликовые подшипники цепи могут выдерживать нагрузку вилочного погрузчика при различных нагрузках, обеспечивая бесперебойную работу.

3. Устойчивость к коррозии

Некоторые вилочные погрузчики работают в особо влажных или агрессивных средах, поэтому при изготовлении роликовых подшипников цепи часто используются коррозионностойкие материалы, такие как нержавеющая сталь или оцинкованные покрытия.

4. Низкий уровень шума и вибрации

Высококачественные роликовые подшипники цепей вилочных погрузчиков эффективно снижают уровень шума и вибрации. Это важно для бесперебойной работы вилочного погрузчика и комфорта операторов.

Улучшение характеристик и решения для роликовых подшипников направляющих цепей

1. Оптимизация смазки

Выбор подходящего смазочного масла или консистентной смазки, а также их правильное добавление и смешивание могут снизить трение и повысить износостойкость. Использование синтетических смазочных материалов или наносмазок может значительно повысить эффективность и срок службы подшипника.

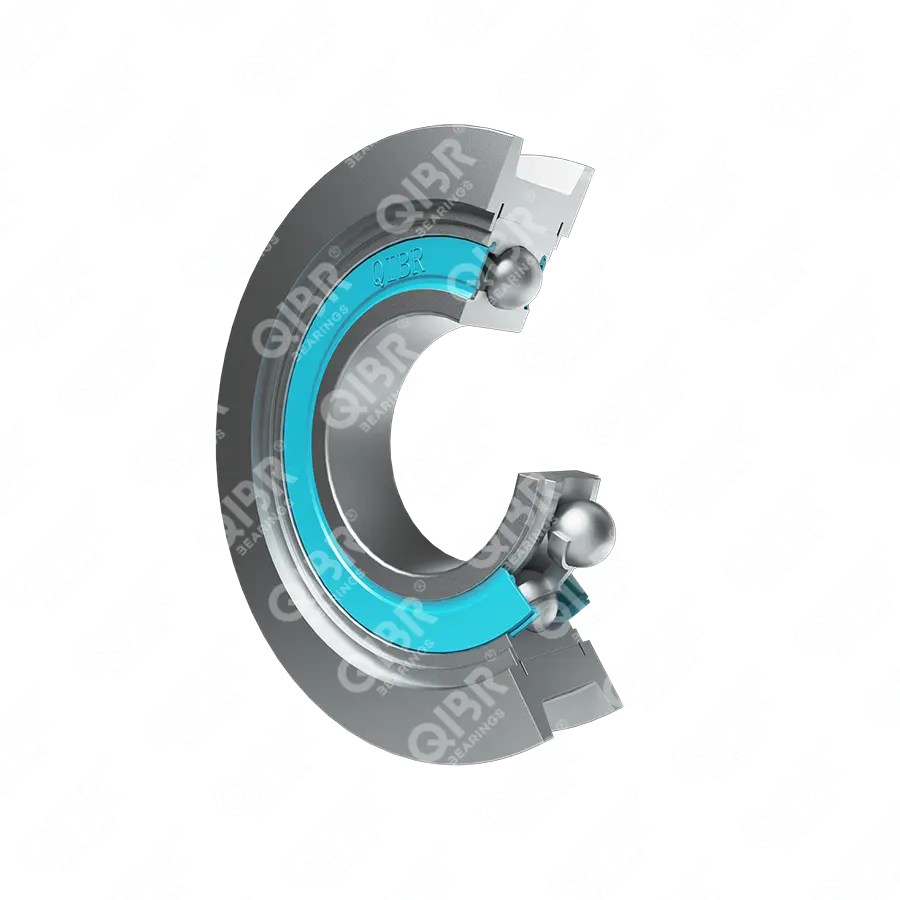

2. Оптимизация дорожки качения

Оптимизация геометрии дорожек качения внутреннего и наружного колец, например, повышение точности дорожек качения и улучшение качества поверхности, снижает трение, минимизирует потери энергии и повышает эффективность подшипника.

3. Усиленная структура уплотнения

Разработка эффективной системы уплотнения для предотвращения попадания в подшипник пыли, грязи, влаги и других внешних загрязнений. Хорошая конструкция уплотнения помогает поддерживать подшипник в чистоте и продлевает срок его службы.

4. Коррозионностойкая конструкция

Для сложных условий эксплуатации (например, в морской или химической среде) использование нержавеющей стали, коррозионностойких покрытий или методов обработки поверхности может повысить устойчивость подшипника к коррозии.

Основные области применения роликовых подшипников направляющих цепей

1. Система привода вилочного погрузчика

В системе привода вилочного погрузчика цепные роликовые подшипники используются для соединения двигателя с ведущими колесами. Вилочные погрузчики требуют мощных двигателей для перевозки и перемещения тяжелых грузов, а цепные роликовые подшипники обеспечивают необходимую поддержку в этом процессе, гарантируя плавную и эффективную передачу мощности.

2. Тяжелое погрузочно-разгрузочное оборудование

Вилочные погрузчики часто используются на складах и заводах для перемещения материалов, где обычно задействованы тяжелые грузы. Роликовые подшипники цепи уменьшают трение между цепью и другими механическими частями, помогая вилочному погрузчику выдерживать большие нагрузки при перемещении, повышая эффективность работы и продлевая срок службы.

3. Высокочастотные условия эксплуатации

В условиях частой эксплуатации вилочных погрузчиков, например, в логистических центрах или на строительных площадках, погрузчики должны работать в течение длительного времени. Роликовые подшипники цепи обеспечивают стабильную работу, уменьшают износ и поломки, повышают долговечность и надежность вилочного погрузчика.

4. Суровые условия работы

Вилочные погрузчики часто работают в тяжелых условиях, таких как влажность, высокая температура или пыль. Цепные роликовые подшипники, благодаря своей герметичной конструкции, предотвращают попадание грязи, влаги и других загрязняющих веществ в подшипник, обеспечивая стабильную работу в таких условиях.