Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

GCr15

Бренд

QIBR/OEM/Neutral

Применения

Automotive Industry, Aerospace Industry, Industrial Machinery, Construction and Agricultural Equipment, Household Appliances, Marine Industry, Medical Equipment, etc

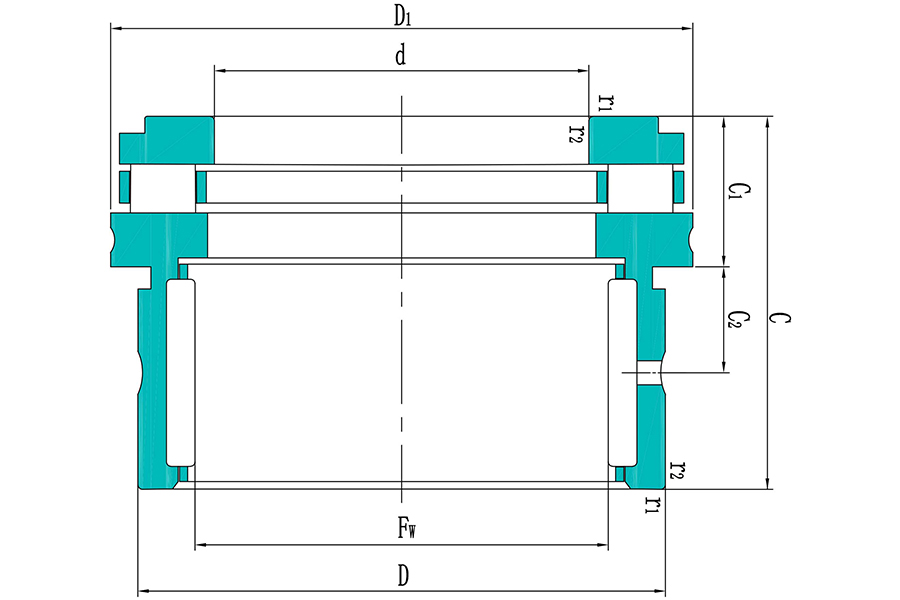

| NO. | Product | Product Number | Базовая динамическая нагрузка, радиальная | Базовая динамическая нагрузка, осевая | Базовая статическая нагрузка, радиальная | Диаметр под роликами (Fw) | Наружный диаметр (d1) | Ширина (C) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

NKXR 15 | 11 KN | 11.2 KN | 14 KN | 15 mm | 23 mm | |

| 2 |

|

NKXR 15 Z | 11 KN | 11.2 KN | 14 KN | 15 mm | 23 mm | |

| 3 |

|

NKXR 17 | 12.1 KN | 12.2 KN | 16.6 KN | 17 mm | 25 mm | |

| 4 |

|

NKXR 17 Z | 12.1 KN | 12.2 KN | 16.6 KN | 17 mm | 25 mm | |

| 5 |

|

NKXR 20 | 16.5 KN | 18.6 KN | 25.5 KN | 20 mm | 30 mm | |

| 6 |

|

NKXR 20 Z | 16.5 KN | 18.6 KN | 25.5 KN | 20 mm | 30 mm | |

| 7 |

|

NKXR 25 | 19 KN | 25 KN | 32.5 KN | 25 mm | 30 mm | |

| 8 |

|

NKXR 25 Z | 19 KN | 25 KN | 32.5 KN | 25 mm | 30 mm | |

| 9 |

|

NKXR 30 | 22.9 KN | 27 KN | 38 KN | 30 mm | 30 mm | |

| 10 |

|

NKXR 30 Z | 22.9 KN | 27 KN | 38 KN | 30 mm | 30 mm | |

| 11 |

|

NKXR 35 | 24.6 KN | 29 KN | 45 KN | 35 mm | 30 mm | |

| 12 |

|

NKXR35Z | 24.6 KN | 29 KN | 45 KN | 35 mm | 30 mm | |

| 13 |

|

NKXR 40 | 26.4 KN | 43 KN | 51 KN | 40 mm | 32 mm | |

| 14 |

|

NKXR 40 Z | 26.4 KN | 43 KN | 51 KN | 40 mm | 32 mm | |

| 15 |

|

NKXR 45 | 27.5 KN | 45 KN | 57 KN | 45 mm | 32 mm | |

| 16 |

|

NKXR 45 Z | 27.5 KN | 45 KN | 57 KN | 45 mm | 32 mm | |

| 17 |

|

NKXR 50 | 38 KN | 47.5 KN | 78 KN | 50 mm | 35 mm | |

| 18 |

|

NKXR 50 Z | 38 KN | 47.5 KN | 78 KN | 50 mm | 35 mm |

Особенности и преимущества комбинированных игольчатых и упорных цилиндрических роликоподшипников QIBR

Комбинированные игольчатые и упорные цилиндрические роликоподшипники QIBR решают множество ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1. Несущая способность при сложной нагрузке

Этот комбинированный подшипник может одновременно воспринимать радиальную и осевую нагрузки, и подходит для сложных условий, где две нагрузки действуют одновременно во время работы, особенно для приложений, которые должны воспринимать крутящий момент и радиальную силу.

2. Экономия места и упрощение конструкции

Поскольку этот комбинированный подшипник воспринимает радиальные и осевые нагрузки одновременно, обычно нет необходимости использовать в конструкции несколько подшипников для разделения различных типов нагрузок, что позволяет экономить монтажное пространство.

В некоторых компактных конструкциях использование этого комбинированного подшипника может значительно упростить процесс сборки, уменьшить количество деталей и снизить затраты на производство и обслуживание.

3. Сильная адаптивность

Комбинированный игольчатый и упорный цилиндрический роликоподшипник может адаптироваться к сложным условиям работы, нормально работать при высоких нагрузках, вибрациях, ударах и т.д., а также адаптироваться к изменениям нагрузки в различных направлениях.

Улучшение характеристик и решения для комбинированного подшипника QIBR с игольчатыми и упорными цилиндрическими роликами

1. Улучшенные материалы

Выбор высокопроизводительных материалов: Использование материалов с более высокой твердостью, износостойкостью и коррозионной стойкостью может значительно повысить долговечность и стабильность подшипников.

2. Оптимизированная конструкция сепаратора

Оптимизация конструкции сепаратора: Оптимизация конструкции сепаратора для достижения лучшего расположения игольчатых роликов и равномерного распределения нагрузки. Улучшение структуры сепаратора может уменьшить взаимное столкновение игольчатых роликов и улучшить эксплуатационную стабильность и эффективность.

3. Улучшение характеристик смазки

Высокоэффективные смазочные материалы: Используйте консистентную смазку или смазочное масло, которые лучше подходят для работы в условиях высоких температур и высокого давления, чтобы обеспечить стабильную работу смазочного масла при длительной эксплуатации, тем самым снижая трение в подшипнике и повышая его долговечность.

4. Улучшенная точность

Технология прецизионной обработки: Повышение точности изготовления и уменьшение погрешности между компонентами подшипника обеспечивают более равномерный и стабильный контакт между игольчатыми роликами и сепараторами. Это позволяет не только улучшить характеристики подшипника, но и продлить срок службы, а также снизить уровень шума и вибрации.

Основные области применения комбинированных игольчатых и упорных цилиндрических роликоподшипников QIBR

1. Автоматическая трансмиссия

В автоматической трансмиссии этот тип подшипников используется для восприятия больших осевых и радиальных нагрузок для обеспечения плавной работы трансмиссии.

2. Высокоточные станки

В прецизионных станках с ЧПУ, особенно в высокоскоростных шпинделях, комбинированные подшипники используются для обеспечения высокой жесткости и высокой точности, чтобы обеспечить точность обработки и стабильность станков.

3. Роботизированные манипуляторы

В промышленных роботах, особенно в шарнирных частях, требующих высоких нагрузок, комбинированные подшипники могут обеспечить более высокую несущую способность по крутящему моменту для обеспечения гибкости и стабильности манипулятора робота.

4. Высокоскоростное вращающееся оборудование

Например, в высококлассном спортивном оборудовании, таком как лыжи, гонки и парусный спорт, комбинированные подшипники могут обеспечить точное управление вращением и стабильность для обеспечения спортивных результатов и безопасности.