Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

Количество шариков

19-30

Сферический диаметр

5.556mm-15.081mm

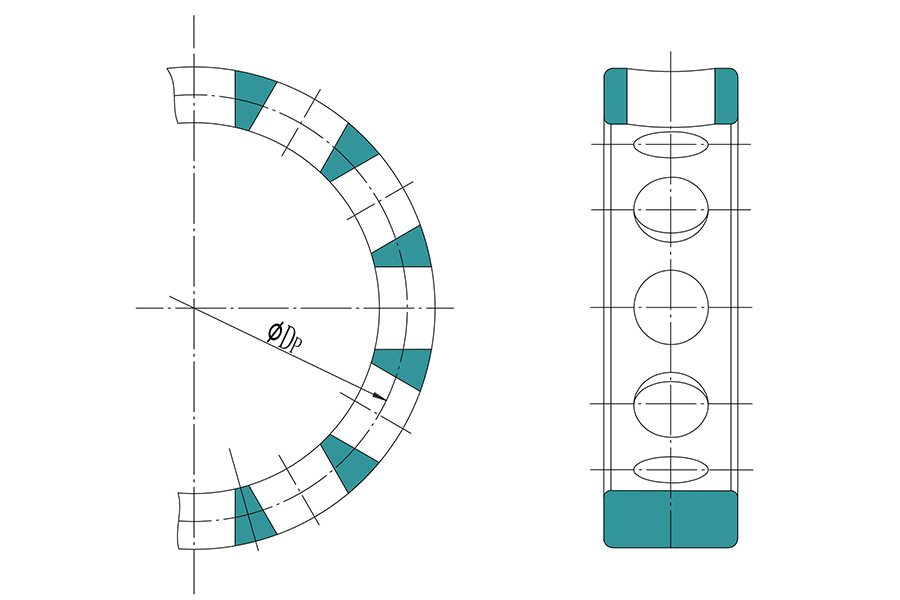

Центральный диаметр (Dp)

42.5mm-165mm

Применения

Bearing assemblies

| NO. | Product | Product Number | Центральный диаметр (Dp) | Количество шариков | Сферический диаметр |

|---|---|---|---|---|---|

| 1 |

|

3C06 | 42.5 mm | 19 | 5.556 mm |

| 2 |

|

3C07 | 48.5 mm | 19 | 6.35 mm |

| 3 |

|

3C08 | 54 mm | 22 | 6.35 mm |

| 4 |

|

3C09 | 60 mm | 22 | 6.35 mm |

| 5 |

|

3C12 | 77.5 mm | 24 | 7.938 mm |

| 6 |

|

3C14 | 90 mm | 24 | 9.525 mm |

| 7 |

|

7012 | 77.46 mm | 19 | 10.319mm |

| 8 |

|

7013 | 82.5 mm | 21 | 10.319 mm |

| 9 |

|

7014 | 90 mm | 20 | 11.906 mm |

| 10 |

|

7015 | 95 mm | 21 | 11.906 mm |

| 11 |

|

7016 | 102.5 mm | 20 | 13.494 mm |

| 12 |

|

7017 | 107.5 mm | 21 | 13.494 mm |

| 13 |

|

7018 | 115 mm | 20 | 15.081 mm |

| 14 |

|

7019 | 120 mm | 22 | 14.288 mm |

| 15 |

|

7020 | 125 mm | 22 | 15.081 mm |

| 16 |

|

30BNR | 42.5 mm | 19 | 5.556 mm |

| 17 |

|

40BNR | 54 mm | 22 | 5.953 mm |

| 18 |

|

45BNR | 60 mm | 22 | 6.35 mm |

| 19 |

|

50BNR | 65 mm | 24 | 6.35 mm |

| 20 |

|

60BNR | 77.5 mm | 26 | 7.144 mm |

| 21 |

|

65BNR | 82.5 mm | 28 | 7.144 mm |

| 22 |

|

70BNR | 90 mm | 25 | 8.731 mm |

| 23 |

|

80BNR | 102.5 mm | 27 | 9.525 mm |

| 24 |

|

90BTR | 115 mm | 26 | 11.113 mm |

| 25 |

|

100BTR | 125 mm | 29 | 11.113 mm |

| 26 |

|

110BTR | 140 mm | 29 | 12.7 mm |

| 27 |

|

120BTR | 150 mm | 30 | 12.7 mm |

| 28 |

|

130BTR | 165 mm | 26 | 15.081 mm |

1. Роль сепаратора

Разделять шарики: обеспечить достаточное расстояние между элементами качения (шариками), чтобы предотвратить их столкновение или трение друг о друга.

Уменьшить трение: Конструкция сепаратора может помочь уменьшить трение в подшипнике, тем самым повышая эффективность и срок службы подшипника.

Поддерживать шарики: Сепаратор обеспечивает опорную конструкцию для того, чтобы шарики сохраняли правильное положение и расположение в подшипнике, снижая вибрацию и шум.

Направление смазочной жидкости: Сепаратор может эффективно направлять поток смазочного масла или консистентной смазки для обеспечения смазочных характеристик подшипника.

2. Области применения сепараторов

Высокоскоростные двигатели: такие как электроинструменты, двигатели, ветряные турбины и т.д.

Прецизионные приборы: такие как высокоскоростные прецизионные станки, оптическое оборудование и т.д.

Автомобильная промышленность: используется в автомобильных силовых установках, системах рулевого управления и т.д.

Аэрокосмическая промышленность: используется для вращающихся частей самолетов, спутников и т.д.

3. Соображения, касающиеся конструкции сепаратора

Несущая способность: Сепаратор должен нормально работать в условиях высокой нагрузки и не должен деформироваться или выходить из строя.

Рабочая скорость: При работе на высокой скорости сепаратор должен иметь низкий коэффициент трения, чтобы уменьшить накопление тепла.

Долговечность: Сепаратор должен обладать высокой износостойкостью и коррозионной стойкостью, особенно при работе в тяжелых условиях.

Простота установки: Конструкция сепаратора должна быть простой в установке и обслуживании, чтобы обеспечить нормальную работу подшипника.