Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

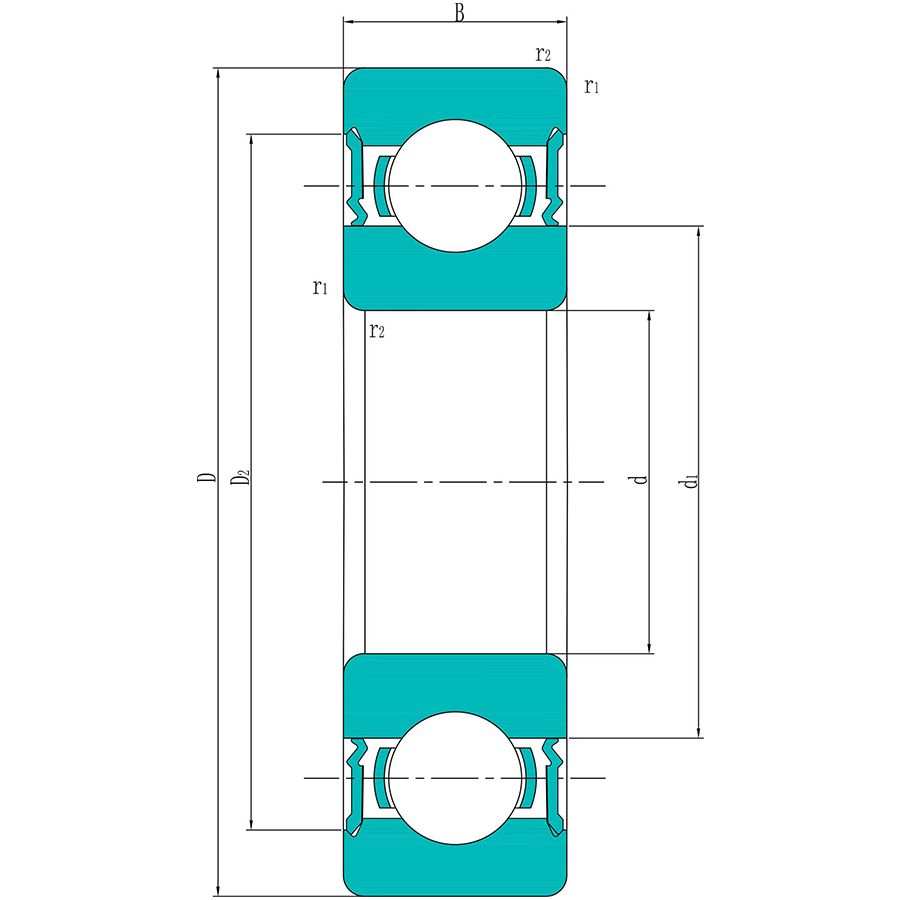

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Внутренний диаметр кольца

3mm-25mm

Наружный диаметр кольца

8mm-70mm

Ширина

3mm-20mm

Динамическая радиальная нагрузка

5lbf-1888lbf

Материал

NDI/POM Polyurethane

Базовая статическая нагрузка, радиальная

2lbf-1059lbf

Макс. частота вращения

7.8-42.6(X1000 rpm)

Бренд

QIBR/OEM/Neutral

| NO. | Product | Product Number | Материал шарика | Наружный диаметр (D) | Материал кольца | Длина винта | Материал щита | Ширина |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

6203 2rs | Chrome Steel | 50 mm | Chrome Steel | 12 mm | NBR | 18 mm |

| 2 |

|

6203 2rs | Chrome Steel | 60 mm | Chrome Steel | 12 mm | NBR | 18 mm |

| 3 |

|

623 2rs | Chrome Steel | 15 mm | Chrome Steel | 5 mm | NBR | 4 mm |

| 4 |

|

624 2rs | Chrome Steel | 15 mm | Chrome Steel | 5 mm | NBR | 5 mm |

| 5 |

|

624 2rs | Chrome Steel | 30 mm | Chrome Steel | 5 mm | NBR | 5 mm |

| 6 |

|

683 2rs | Chrome Steel | 10 mm | Chrome Steel | 4 mm | NBR | 3 mm |

| 7 |

|

683 2rs | Chrome Steel | 12 mm | Chrome Steel | 4 mm | NBR | 3 mm |

| 8 |

|

693 2rs | Chrome Steel | 10 mm | Chrome Steel | 5 mm | NBR | 4 mm |

| 9 |

|

693 2rs | Chrome Steel | 10 mm | Chrome Steel | 5 mm | NBR | 5 mm |

| 10 |

|

693 2rs | Chrome Steel | 10 mm | Chrome Steel | 4 mm | NBR | 5 mm |

| 11 |

|

693 2rs | Chrome Steel | 10 mm | Chrome Steel | 5 mm | NBR | 6 mm |

| 12 |

|

MR63 2rs | Chrome Steel | 8 mm | Chrome Steel | 4 mm | NBR | 3 mm |

| 13 |

|

604 2rs | Chrome Steel | 16 mm | Chrome Steel | 6 mm | NBR | 5 mm |

| 14 |

|

684 2rs | Chrome Steel | 11 mm | Chrome Steel | 5 mm | NBR | 4 mm |

| 15 |

|

684 2rs | Chrome Steel | 13 mm | Chrome Steel | 5 mm | NBR | 4 mm |

| 16 |

|

684 2rs | Chrome Steel | 13 mm | Chrome Steel | 5 mm | NBR | 8 mm |

| 17 |

|

684 2rs | Chrome Steel | 14 mm | Chrome Steel | 5 mm | NBR | 6 mm |

| 18 |

|

605 2rs | Chrome Steel | 18 mm | Chrome Steel | 6 mm | NBR | 5 mm |

| 19 |

|

605 2rs | Chrome Steel | 19 mm | Chrome Steel | 6 mm | NBR | 7 mm |

| 20 |

|

625 2rs | Chrome Steel | 20 mm | Chrome Steel | 6 mm | NBR | 5 mm |

| 21 |

|

625 2rs | Chrome Steel | 22 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 22 |

|

625 2rs | Chrome Steel | 22 mm | Chrome Steel | 8 mm | NBR | 9 mm |

| 23 |

|

625 2rs | Chrome Steel | 24 mm | Chrome Steel | 6 mm | NBR | 5 mm |

| 24 |

|

625 2rs | Chrome Steel | 25 mm | Chrome Steel | 8 mm | NBR | 9 mm |

| 25 |

|

685 2rs | Chrome Steel | 16 mm | Chrome Steel | 6 mm | NBR | 5 mm |

| 26 |

|

685 2rs | Chrome Steel | 17 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 27 |

|

685 2rs | Chrome Steel | 16 mm | Chrome Steel | 6 mm | NBR | 8 mm |

| 28 |

|

606 2rs | Chrome Steel | 21 mm | Chrome Steel | 8 mm | NBR | 9 mm |

| 29 |

|

606 2rs | Chrome Steel | 22 mm | Chrome Steel | 8 mm | NBR | 6 mm |

| 30 |

|

606 2rs | Chrome Steel | 24 mm | Chrome Steel | 8 mm | NBR | 6 mm |

| 31 |

|

626 2rs | Chrome Steel | 24 mm | Chrome Steel | 8 mm | NBR | 8 mm |

| 32 |

|

626 2rs | Chrome Steel | 26 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 33 |

|

626 2rs | Chrome Steel | 26 mm | Chrome Steel | 8 mm | NBR | 12 mm |

| 34 |

|

626 2rs | Chrome Steel | 26 mm | Chrome Steel | 8 mm | NBR | 8 mm |

| 35 |

|

626 2rs | Chrome Steel | 28 mm | Chrome Steel | 8 mm | NBR | 13 mm |

| 36 |

|

626 2rs | Chrome Steel | 28 mm | Chrome Steel | 8 mm | NBR | 6 mm |

| 37 |

|

626 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 38 |

|

626 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 12 mm |

| 39 |

|

626 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 6 mm |

| 40 |

|

626 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 9 mm |

| 41 |

|

626 2rs | Chrome Steel | 33 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 42 |

|

626 2rs | Chrome Steel | 35 mm | Chrome Steel | 8 mm | NBR | 14 mm |

| 43 |

|

626 2rs | Chrome Steel | 40 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 44 |

|

696 2rs | Chrome Steel | 18 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 45 |

|

696 2rs | Chrome Steel | 18 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 46 |

|

696 2rs | Chrome Steel | 20 mm | Chrome Steel | 12 mm | NBR | 5 mm |

| 47 |

|

696 2rs | Chrome Steel | 20 mm | Chrome Steel | 8 mm | NBR | 6 mm |

| 48 |

|

696 2rs | Chrome Steel | 20 mm | Chrome Steel | 8 mm | NBR | 8 mm |

| 49 |

|

696 2rs | Chrome Steel | 22 mm | Chrome Steel | 12 mm | NBR | 5 mm |

| 50 |

|

696 2rs | Chrome Steel | 22 mm | Chrome Steel | 8 mm | NBR | 5 mm |

| 51 |

|

608 2rs | Chrome Steel | 24 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 52 |

|

608 2rs | Chrome Steel | 26 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 53 |

|

608 2rs | Chrome Steel | 28 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 54 |

|

608 2rs | Chrome Steel | 28 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 55 |

|

608 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 11 mm |

| 56 |

|

608 2rs | Chrome Steel | 30 mm | Chrome Steel | 8 mm | NBR | 7 mm |

| 57 |

|

608 2rs | Chrome Steel | 31 mm | Chrome Steel | 10 mm | NBR | 12 mm |

| 58 |

|

608 2rs | Chrome Steel | 35 mm | Chrome Steel | 10 mm | NBR | 15 mm |

| 59 |

|

608 2rs | Chrome Steel | 35 mm | Chrome Steel | 10 mm | NBR | 15 mm |

| 60 |

|

608 2rs | Chrome Steel | 35 mm | Chrome Steel | 10 mm | NBR | 18 mm |

| 61 |

|

608 2rs | Chrome Steel | 35 mm | Chrome Steel | 8 mm | NBR | 15 mm |

| 62 |

|

608 2rs | Chrome Steel | 36 mm | Chrome Steel | 8 mm | NBR | 10 mm |

| 63 |

|

608 2rs | Chrome Steel | 40 mm | Chrome Steel | 10 mm | NBR | 11 mm |

| 64 |

|

608 2rs | Chrome Steel | 40 mm | Chrome Steel | 10 mm | NBR | 13 mm |

| 65 |

|

608 2rs | Chrome Steel | 45 mm | Chrome Steel | 10 mm | NBR | 14 mm |

| 66 |

|

608 2rs | Chrome Steel | 48 mm | Chrome Steel | 10 mm | NBR | 16 mm |

| 67 |

|

638 2rs | Chrome Steel | 40 mm | Chrome Steel | 10 mm | NBR | 20 mm |

| 68 |

|

638 2rs | Chrome Steel | 50 mm | Chrome Steel | 10 mm | NBR | 20 mm |

| 69 |

|

6000 2rs | Chrome Steel | 32 mm | Chrome Steel | 10 mm | NBR | 10 mm |

| 70 |

|

6000 2rs | Chrome Steel | 34 mm | Chrome Steel | 10 mm | NBR | 11 mm |

| 71 |

|

6000 2rs | Chrome Steel | 35 mm | Chrome Steel | 10 mm | NBR | 11 mm |

| 72 |

|

6000 2rs | Chrome Steel | 38 mm | Chrome Steel | 10 mm | NBR | 10 mm |

| 73 |

|

6000 2rs | Chrome Steel | 40 mm | Chrome Steel | 10 mm | NBR | 10 mm |

| 74 |

|

6200 2rs | Chrome Steel | 36 mm | Chrome Steel | 10 mm | NBR | 13 mm |

| 75 |

|

6200 2rs | Chrome Steel | 36 mm | Chrome Steel | 10 mm | NBR | 16 mm |

| 76 |

|

6200 2rs | Chrome Steel | 40 mm | Chrome Steel | 12 mm | NBR | 12 mm |

| 77 |

|

6200 2rs | Chrome Steel | 50 mm | Chrome Steel | 12 mm | NBR | 12 mm |

| 78 |

|

6200 2rs | Chrome Steel | 60 mm | Chrome Steel | 12 mm | NBR | 12 mm |

| 79 |

|

6001 2rs | Chrome Steel | 40 mm | Chrome Steel | 12 mm | NBR | 13 mm |

| 80 |

|

6001 2rs | Chrome Steel | 45 mm | Chrome Steel | 12 mm | NBR | 14 mm |

| 81 |

|

6202 2rs | Chrome Steel | 38 mm | Chrome Steel | 12 mm | NBR | 10 mm |

| 82 |

|

6202 2rs | Chrome Steel | 40 mm | Chrome Steel | 12 mm | NBR | 18 mm |

| 83 |

|

6202 2rs | Chrome Steel | 50 mm | Chrome Steel | 12 mm | NBR | 20 mm |

| 84 |

|

6002 2rs | Chrome Steel | 50 mm | Chrome Steel | 12 mm | NBR | 15 mm |

| 85 |

|

6202 2rs | Chrome Steel | 43 mm | Chrome Steel | 12 mm | NBR | 15 mm |

| 86 |

|

6202 2rs | Chrome Steel | 48 mm | Chrome Steel | 12 mm | NBR | 15 mm |

| 87 |

|

6202 2rs | Chrome Steel | 55 mm | Chrome Steel | 12 mm | NBR | 15 mm |

| 88 |

|

6004 2rs | Chrome Steel | 53 mm | Chrome Steel | 12 mm | NBR | 20 mm |

| 89 |

|

6004 2rs | Chrome Steel | 56 mm | Chrome Steel | 12 mm | NBR | 20 mm |

| 90 |

|

6004 2rs | Chrome Steel | 70 mm | Chrome Steel | 12 mm | NBR | 18 mm |

| 91 |

|

6004 2rs | Chrome Steel | 65 mm | Chrome Steel | 12 mm | NBR | 19 mm |

Особенности и преимущества подшипника QIBR с полиуретановым покрытием с винтом

Подшипник QIBR с полиуретановым покрытием с винтом решает несколько ключевых проблем в различных областях, в основном отраженных в следующих аспектах:

1. Износостойкость

Подшипник с полиуретановым покрытием QIBR с винтом обладает превосходной износостойкостью, что снижает износ при длительной эксплуатации и продлевает срок службы, особенно подходит для условий с высокой нагрузкой или высоким коэффициентом трения.

2. Поглощение ударов и снижение шума

Подшипник с полиуретановым покрытием QIBR с винтом обладает хорошей эластичностью и буферными свойствами, эффективно поглощая вибрации и снижая шум.

3. Устойчивость к воздействию масла и химической коррозии

Подшипник с полиуретановым покрытием с винтом QIBR обладает хорошей устойчивостью к воздействию масел, растворителей и различных химических веществ.

4. Устойчивость к ударам

Высокая эластичность подшипника QIBR с полиуретановым покрытием с винтом обеспечивает ему хорошую ударопрочность, что делает его пригодным для использования в средах с ударными нагрузками.

Улучшение характеристик и решения для подшипников QIBR с полиуретановым покрытием с винтом

1. Повышенная износостойкость

Добавление армирующих материалов, таких как сажа, керамика и металлические порошки, позволяет повысить твердость и износостойкость полиуретана, что позволяет ему сохранять стабильные характеристики при высоких нагрузках и длительном использовании.

2. Улучшенная масло- и химическая стойкость

В зависимости от условий эксплуатации подшипника можно выбрать полиуретановые составы с повышенной химической коррозией и маслостойкостью, что увеличивает срок службы подшипника в условиях химического и масляного загрязнения.

3. Оптимизация толщины полиуретанового слоя

Толщина полиуретанового слоя напрямую влияет на производительность аутсорсингового полиуретанового подшипника. Соответствующая толщина может повысить ударопрочность и износостойкость подшипника. Однако слишком толстый слой полиуретана может снизить жесткость подшипника и повлиять на его рабочие характеристики. Разумный выбор толщины полиуретанового слоя может удовлетворить требования к амортизации и износостойкости, сохраняя при этом грузоподъемность и эксплуатационную стабильность подшипника.

4. Оптимизация структуры внутреннего и наружного кольца

Оптимизация геометрических форм и размеров внутреннего и наружного колец позволяет равномерно нагружать полиуретановый слой, предотвращая локальный износ.

Основные области применения подшипников QIBR с полиуретановым покрытием с винтом

1. Автомобильная промышленность

Полиуретановые подшипники широко используются в автомобильной промышленности, особенно в системах подвески, привода и тормозных системах. Благодаря способности полиуретанового материала поглощать вибрации, снижать шум и обеспечивать высокую прочность, он используется в: автомобильных колесных осях и системах подвески, компонентах двигателя и трансмиссии, колесах и тормозных системах.

2. Машиностроение

В машиностроении полиуретановые подшипники используются в различном механическом оборудовании, требующем износостойкости и высокой грузоподъемности. Эластичность и прочность позволяют им работать в условиях больших нагрузок и сильных ударов.

3. Спортивное оборудование

Полиуретановые подшипники широко используются в различном спортивном оборудовании и инструментах, особенно в компонентах, требующих износостойкости и ударопрочности. К ним относятся: скейтборды, лыжи, роликовые коньки и другие спортивные товары.

4. Аэрокосмическая промышленность

В аэрокосмической промышленности полиуретановые подшипники используются в некоторых компонентах самолетов благодаря их превосходным высокотемпературным и износостойким свойствам. Они выдерживают высокоскоростную работу и экстремальные нагрузки окружающей среды.

5. Сельскохозяйственная техника

Полиуретановые подшипники также играют важную роль в сельскохозяйственной технике, особенно в условиях, когда они часто подвергаются воздействию почвы, влаги и различных материалов. Устойчивость к коррозии и износостойкость полиуретана делают его очень подходящим.