Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

52100, 100Cr6, SUJ2, stainless steel

Бренд

QIBR/OEM/Neutral

Применения

Conveyor systems, agricultural machinery, and textile machinery, etc

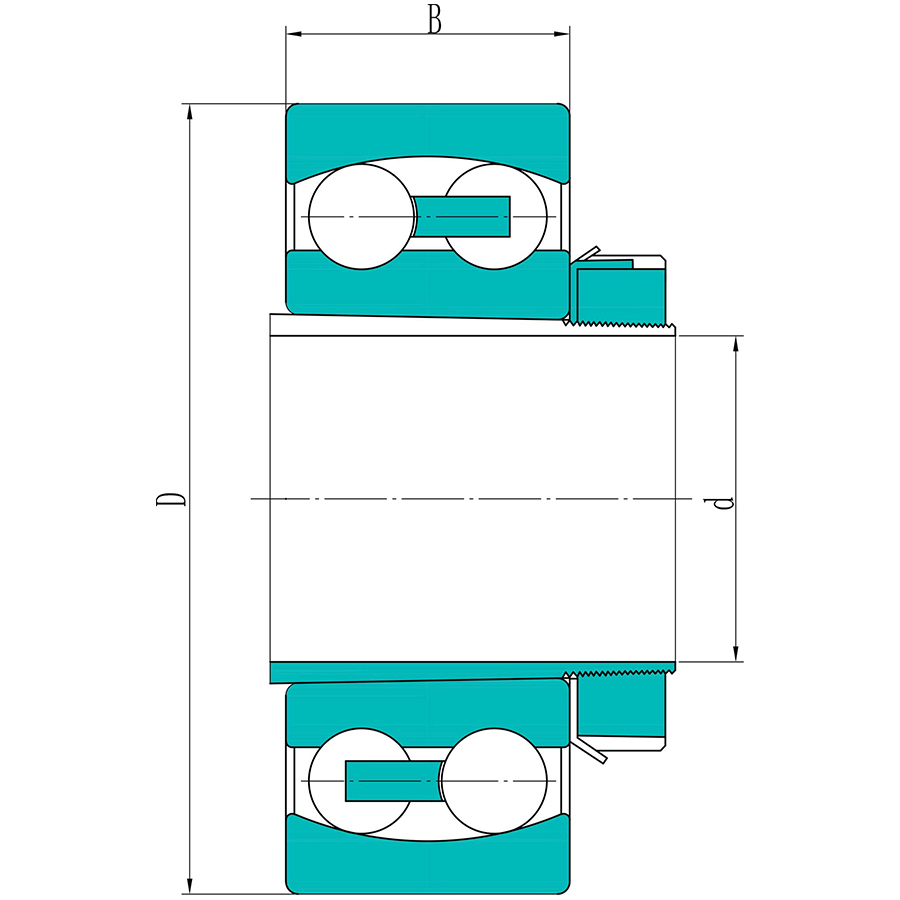

Внутренний диаметр

17-115mm

Наружный диаметр

47-230mm

Вес

0.16-11kg

Упаковка

Standard Export Package

| NO. | Product | Product Number | Переходная втулка | Отверстие | Вес | Наружный диаметр (D) | Ширина (B) |

|---|---|---|---|---|---|---|---|

| 1 |

|

1204 EKTN9+H 204 | H 204 | 17 mm | 0.16 kg | 47 mm | 14 mm |

| 2 |

|

1205 EKTN9+H 205 | H 205 | 20 mm | 0.21 kg | 52 mm | 15 mm |

| 3 |

|

2205 E-2RS1KTN9+H 305 E | H 305 E | 20 mm | 0.23 kg | 52 mm | 18 mm |

| 4 |

|

2205 EKTN9+H 305 | H 305 | 20 mm | 0.23 kg | 52 mm | 18 mm |

| 5 |

|

1305 EKTN9+H 305 | H 305 | 20 mm | 0.33 kg | 62 mm | 17 mm |

| 6 |

|

2305 E-2RS1KTN9+H 2305 | H 2305 | 20 mm | 0.42 kg | 62 mm | 24 mm |

| 7 |

|

2305 EKTN9+H 2305 | H 2305 | 20 mm | 0.42 kg | 62 mm | 24 mm |

| 8 |

|

1206 EKTN9+H 206 | H 206 | 25 mm | 0.32 kg | 62 mm | 16 mm |

| 9 |

|

2206 E-2RS1KTN9+H 306 E | H 306 E | 25 mm | 0.36 kg | 62 mm | 20 mm |

| 10 |

|

2206 EKTN9+H 306 | H 306 | 25 mm | 0.36 kg | 62 mm | 20 mm |

| 11 |

|

1306 EKTN9+H 306 | H 306 | 25 mm | 0.49 kg | 72 mm | 19 mm |

| 12 |

|

2306 E-2RS1KTN9+H 2306 | H 2306 | 25 mm | 0.62 kg | 72 mm | 27 mm |

| 13 |

|

2306 K+H 2306 | H 2306 | 25 mm | 0.61 kg | 72 mm | 27 mm |

| 14 |

|

1207 EKTN9+H 207 | H 207 | 30 mm | 0.44 kg | 72 mm | 17 mm |

| 15 |

|

2207 E-2RS1KTN9+H 307 E | H 307 E | 30 mm | 0.55 kg | 72 mm | 23 mm |

| 16 |

|

2207 EKTN9+H 307 | H 307 | 30 mm | 0.54 kg | 72 mm | 23 mm |

| 17 |

|

1307 EKTN9+H 307 | H 307 | 30 mm | 0.65 kg | 80 mm | 21 mm |

| 18 |

|

2307 E-2RS1KTN9+H 2307 E | H 2307 E | 30 mm | 0.86 kg | 80 mm | 31 mm |

| 19 |

|

2307 EKTN9+H 2307 | H 2307 | 30 mm | 0.84 kg | 80 mm | 31 mm |

| 20 |

|

1208 EKTN9+H 208 | H 208 | 35 mm | 0.58 kg | 80 mm | 18 mm |

| 21 |

|

2208 E-2RS1KTN9+H 308 E | H 308 E | 35 mm | 0.67 kg | 80 mm | 23 mm |

| 22 |

|

2208 EKTN9+H 308 | H 308 | 35 mm | 0.58 kg | 80 mm | 23 mm |

| 23 |

|

1308 EKTN9+H 308 | H 308 | 35 mm | 0.85 kg | 90 mm | 23 mm |

| 24 |

|

2308 EKTN9+H 2308 | H 2308 | 35 mm | 1.1 kg | 90 mm | 33 mm |

| 25 |

|

2308 E-2RS1KTN9+H 2308 | H 2308 | 35 mm | 1.2 kg | 90 mm | 33 mm |

| 26 |

|

1209 EKTN9+H 209 | H 209 | 40 mm | 0.68 kg | 85 mm | 19 mm |

| 27 |

|

2209 E-2RS1KTN9+H 309 E | H 309 E | 40 mm | 0.76 kg | 85 mm | 23 mm |

| 28 |

|

2209 EKTN9+H 309 | H 309 | 40 mm | 0.78 kg | 85 mm | 23 mm |

| 29 |

|

1309 EKTN9+H 309 | H 309 | 40 mm | 1.2 kg | 100 mm | 25 mm |

| 30 |

|

2309 EKTN9+H 2309 | H 2309 | 40 mm | 1.4 kg | 100 mm | 36 mm |

| 31 |

|

2309 E-2RS1KTN9+H 2309 | H 2309 | 40 mm | 1.55 kg | 100 mm | 36 mm |

| 32 |

|

1210 EKTN9+H 210 | H 210 | 45 mm | 0.77 kg | 90 mm | 20 mm |

| 33 |

|

2210 E-2RS1KTN9+H 310 E | H 310 E | 45 mm | 0.84 kg | 90 mm | 23 mm |

| 34 |

|

2210 EKTN9+H 310 | H 310 | 45 mm | 0.87 kg | 90 mm | 23 mm |

| 35 |

|

1310 EKTN9+H 310 | H 310 | 45 mm | 1.45 kg | 110 mm | 27 mm |

| 36 |

|

2310 E-2RS1KTN9+H 2310 | H 2310 | 45 mm | 2 kg | 110 mm | 40 mm |

| 37 |

|

2310 K+H 2310 | H 2310 | 45 mm | 1.9 kg | 110 mm | 40 mm |

| 38 |

|

1211 EKTN9+H 211 | H 211 | 50 mm | 0.99 kg | 100 mm | 21 mm |

| 39 |

|

2211 E-2RS1KTN9+H 311 E | H 311 E | 50 mm | 1.1 kg | 100 mm | 25 mm |

| 40 |

|

2211 EKTN9+H 311 | H 311 | 50 mm | 1.15 kg | 100 mm | 25 mm |

| 41 |

|

1311 EKTN9+H 311 | H 311 | 50 mm | 1.9 kg | 120 mm | 29 mm |

| 42 |

|

2311 K+H 2311 | H 2311 | 50 mm | 2.4 kg | 120 mm | 43 mm |

| 43 |

|

1212 EKTN9+H 212 | H 212 | 55 mm | 1.2 kg | 110 mm | 22 mm |

| 43 |

|

1212 EKTN9 | 55 mm | 1.2 kg | 110 mm | 22 mm | |

| 44 |

|

2212 E-2RS1KTN9+H 312 E | H 312 E | 55 mm | 1.4 kg | 110 mm | 28 mm |

| 45 |

|

2212 EKTN9+H 312 | H 312 | 55 mm | 1.45 kg | 110 mm | 28 mm |

| 46 |

|

1312 EKTN9+H 312 | H 312 | 55 mm | 2.15 kg | 130 mm | 31 mm |

| 47 |

|

2312 K+H 2312 | H 2312 | 55 mm | 2.95 kg | 130 mm | 46 mm |

| 48 |

|

1213 EKTN9+H 213 | H 213 | 60 mm | 1.45 kg | 120 mm | 23 mm |

| 49 |

|

2213 E-2RS1KTN9+H 313 E | H 313 E | 60 mm | 1.75 kg | 120 mm | 31 mm |

| 50 |

|

2213 EKTN9+H 313 | H 313 | 60 mm | 1.8 kg | 120 mm | 31 mm |

| 50 |

|

1313 EKTN9+H 313 | H 313 | 60 mm | 2.85 kg | 140 mm | 33 mm |

| 52 |

|

2313 K+H 2313 | H 2313 | 60 mm | 3.6 kg | 140 mm | 48 mm |

| 53 |

|

1215 K+H 215 | H 215 | 65 mm | 2 kg | 130 mm | 25 mm |

| 54 |

|

2215 EKTN9+H 315 | H 315 | 65 mm | 2.3 kg | 130 mm | 31 mm |

| 55 |

|

1315 K+H 315 | H 315 | 65 mm | 4.2 kg | 160 mm | 37 mm |

| 56 |

|

2315 K+H 2315 | H 2315 | 65 mm | 5.55 kg | 160 mm | 55 mm |

| 57 |

|

1216 K+H 216 | H 216 | 70 mm | 2.4 kg | 140 mm | 26 mm |

| 58 |

|

2216 EKTN9+H 316 | H 316 | 70 mm | 2.85 kg | 140 mm | 33 mm |

| 59 |

|

1316 K+H 316 | H 316 | 70 mm | 5 kg | 170 mm | 39 mm |

| 60 |

|

2316 K+H 2316 | H 2316 | 70 mm | 7.1 kg | 170 mm | 58 mm |

| 61 |

|

1217 K+H 217 | H 217 | 75 mm | 2.95 kg | 150 mm | 28 mm |

| 62 |

|

2217 K+H 317 | H 317 | 75 mm | 3.3 kg | 150 mm | 36 mm |

| 63 |

|

1317 K+H 317 | H 317 | 75 mm | 6 kg | 180 mm | 41 mm |

| 64 |

|

1218 K+H 218 | H 218 | 80 mm | 3.5 kg | 160 mm | 30 mm |

| 65 |

|

2218 K+H 318 | H 318 | 80 mm | 5.5 kg | 160 mm | 40 mm |

| 66 |

|

1318 K+H 318 | H 318 | 80 mm | 6.9 kg | 190 mm | 43 mm |

| 67 |

|

2318 K+H 2318 | H 2318 | 80 mm | 9.8 kg | 190 mm | 64 mm |

| 68 |

|

1219 K+H 219 | H 219 | 85 mm | 4.25 kg | 170 mm | 32 mm |

| 69 |

|

2219 K+H 319 | H 319 | 85 mm | 5.3 kg | 170 mm | 43 mm |

| 70 |

|

1319 K+H 319 | H 319 | 85 mm | 7.9 kg | 200 mm | 45 mm |

| 71 |

|

2319 KM+H 2319 | H 2319 | 85 mm | 11.5 kg | 200 mm | 67 mm |

| 72 |

|

1220 K+H 220 | H 220 | 90 mm | 5 kg | 180 mm | 34 mm |

| 73 |

|

2220 K+H 320 | H 320 | 90 mm | 6.4 kg | 180 mm | 46 mm |

| 74 |

|

1320 K+H 320 | H 320 | 90 mm | 9.65 kg | 215 mm | 47 mm |

| 75 |

|

2320 K+H 2320 | H 2320 | 90 mm | 14 kg | 215 mm | 73 mm |

| 76 |

|

1222 K+H 222 | H 222 | 100 mm | 6.8 kg | 200 mm | 38 mm |

| 77 |

|

2222 K+H 322 | H 322 | 100 mm | 8.85 kg | 200 mm | 53 mm |

| 78 |

|

1322 KM+H 322 | H 322 | 100 mm | 13.5 kg | 240 mm | 50 mm |

| 79 |

|

1224 KM+H 3024 | H 3024 | 110 mm | 8.3 kg | 215 mm | 42 mm |

| 80 |

|

1226 KM+H 3026 | H 3026 | 115 mm | 11 kg | 230 mm | 46 mm |

Самоустанавливающиеся шарикоподшипники QIBR с переходными втулками решили множество ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1. Функция автоматической самоустановки

Самой главной особенностью самоустанавливающихся шарикоподшипников QIBR с переходными втулками является то, что они могут автоматически выравниваться. Потому что относительное положение дорожек качения его внутреннего и наружного колец имеет определенный угол (то есть дорожка качения наружного кольца сферическая). При относительном смещении вала или посадочного места подшипника контактная поверхность шарика и дорожки качения автоматически регулируется, обеспечивая стабильное рабочее состояние подшипника и уменьшая износ, вызванный угловой погрешностью.

2. Несущая способность

Самоустанавливающиеся шарикоподшипники QIBR с переходными втулками обладают относительно высокой грузоподъемностью. Он может выдерживать определенные радиальные и осевые нагрузки.

3. Сильная адаптивность

Самоустанавливающиеся шарикоподшипники QIBR с переходными втулками благодаря своим самоустанавливающимся характеристикам особенно хорошо подходят для случаев, когда в процессе установки возникает осевое отклонение. Например, изгиб вала, неправильная установка гнезда подшипника и т.д., эти ситуации могут вызвать угловые отклонения в подшипнике, но самоустанавливающийся шарикоподшипник может эффективно компенсировать эти проблемы и поддерживать бесперебойную работу.

4. Характеристики соединения

Хотя традиционный метод соединения с помощью ключа прост, он подвержен износу, ослаблению и повреждению шпоночного паза. Переходная втулка позволяет избежать этих проблем благодаря отсутствию шпонок и шпоночных пазов, что повышает стабильность и срок службы соединения.

Улучшение характеристик и решения самоустанавливающегося шарикоподшипника QIBR с переходной втулкой

1. Оптимизация смазки:

Выберите подходящее смазочное масло или консистентную смазку и сделайте соответствующие добавки и смеси для снижения трения и повышения износостойкости. Использование синтетических смазочных материалов или наносмазок может значительно повысить эффективность и срок службы подшипников.

2. Оптимизация дорожки качения

Оптимизируйте геометрию дорожек качения внутреннего и наружного колец, например, увеличьте точность дорожек качения, улучшите качество обработки поверхности, уменьшите трение, сократите потери энергии и тем самым повысьте эффективность работы подшипников.

3. Улучшение качества тел качения

Снижение трения и износа за счет улучшения качества поверхности и твердости тел качения. Использование высокоточных тел качения (например, керамики) может значительно улучшить эксплуатационные характеристики подшипника.

4. Оптимизация конструкции сепаратора

Оптимизация конструкции сепаратора, например, использование термостойких и коррозионностойких материалов и конструкций, для повышения долговечности сепаратора и стабильности подшипника.

Основные области применения самоустанавливающихся шарикоподшипников QIBR с переходными втулками

Подшипники для железнодорожного транспорта

В железнодорожном транспорте самоустанавливающиеся шарикоподшипники справляются с такими проблемами, как неровности пути и смещение колес, обеспечивая плавность и надежность работы транспортного средства.

Пищевое оборудование

Например, в таком оборудовании, как миксеры, упаковочные машины, ленточные конвейеры и т.д., самоустанавливающиеся шарикоподшипники могут адаптироваться к проблемам смещения вала, вызванным вибрацией и изменениями нагрузки во время работы оборудования, обеспечивая стабильную работу оборудования.

Колесные подшипники

Колесные подшипники часто подвергаются воздействию высокоскоростного вращения и неравномерных нагрузок. Самоустанавливающиеся шарикоподшипники могут лучше адаптироваться к проблемам несоосности или смещения вала в колесных системах, уменьшить износ, повысить производительность и долговечность.

Трансмиссионное оборудование

В некоторых системах механических трансмиссий самоустанавливающиеся шарикоподшипники могут эффективно решать проблемы, вызванные неравномерными нагрузками или смещением валов.