Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

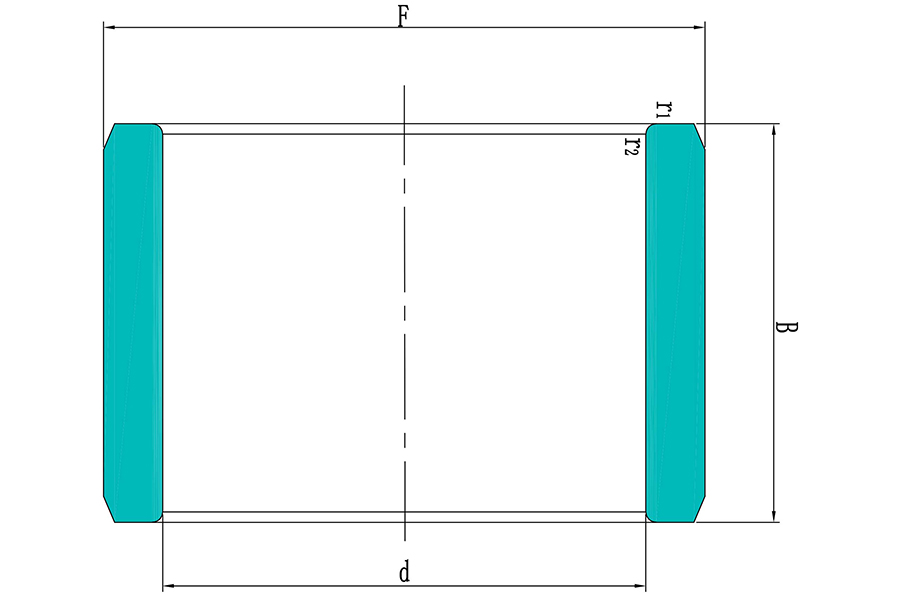

| NO. | Product | Product Number | Диаметр отверстия втулки (d) | Размер фаски (r1,2) | Вес | Диаметр дорожки качения (F) | Ширина (B) |

|---|---|---|---|---|---|---|---|

| 1 |

|

IR 5x8x12 | 0.3 mm | 0.0028 kg | 8 mm | 12 mm | |

| 2 |

|

IR 5x8x16 | 0.3 mm | 0.0037 kg | 8 mm | 16 mm | |

| 3 |

|

IR 6x9x12 | 0.3 mm | 0.003 kg | 9 mm | 12 mm | |

| 4 |

|

IR 6x9x16 | 0.3 mm | 0.0043 kg | 9 mm | 16 mm | |

| 5 |

|

IR 7x10x10.5 | 0.3 mm | 0.0031 kg | 10 mm | 10.5 mm | |

| 6 |

|

LR 7x10x10.5 | 0.3 mm | 0.0031 kg | 10 mm | 10.5 mm | |

| 7 |

|

IR 7x10x12 | 0.3 mm | 0.0036 kg | 10 mm | 12 mm | |

| 8 |

|

IR 7x10x16 | 0.3 mm | 0.0049 kg | 10 mm | 16 mm | |

| 9 |

|

IR 8x12x10 IS1 | 0.3 mm | 0.0048 kg | 12 mm | 10 mm | |

| 10 |

|

IR 8x12x10.5 | 0.3 mm | 0.005 kg | 12 mm | 10.5 mm | |

| 11 |

|

LR 8x12x10.5 | 0.3 mm | 0.005 kg | 12 mm | 10.5 mm | |

| 12 |

|

IR 8x12x12.5 | 0.3 mm | 0.0059 kg | 12 mm | 12.5 mm | |

| 13 |

|

IR 9x12x12 | 0.3 mm | 0.0044 kg | 12 mm | 12 mm | |

| 14 |

|

IR 9x12x16 | 0.3 mm | 0.006 kg | 12 mm | 16 mm | |

| 15 |

|

IR 10x13x12.5 | 0.3 mm | 0.0052 kg | 13 mm | 12.5 mm | |

| 16 |

|

LR 10x13x12.5 | 0.3 mm | 0.0052 kg | 13 mm | 12.5 mm | |

| 17 |

|

IR 10x14x13 | 0.3 mm | 0.0074 kg | 14 mm | 13 mm | |

| 18 |

|

IR 10x14x16 | 0.3 mm | 0.0092 kg | 14 mm | 16 mm | |

| 19 |

|

IR 10x14x20 | 0.3 mm | 0.012 kg | 14 mm | 20 mm | |

| 20 |

|

IR 12x15x12 | 0.3 mm | 0.0057 kg | 15 mm | 12 mm | |

| 21 |

|

IR 12x15x12.5 | 0.3 mm | 0.0061 kg | 15 mm | 12.5 mm | |

| 22 |

|

LR 12x15x12.5 | 0.3 mm | 0.0061 kg | 15 mm | 12.5 mm | |

| 23 |

|

IR 12x15x22.5 | 0.3 mm | 0.011 kg | 15 mm | 22.5 mm | |

| 24 |

|

IR 12x15x16 | 0.3 mm | 0.0076 kg | 15 mm | 16 mm | |

| 25 |

|

IR 12x15x16.5 | 0.3 mm | 0.0081 kg | 15 mm | 16.5 mm | |

| 26 |

|

LR 12x15x22.5 | 0.3 mm | 0.011 kg | 15 mm | 22.5 mm | |

| 27 |

|

IR 12x16x13 | 0.3 mm | 0.0085 kg | 16 mm | 13 mm | |

| 28 |

|

IR 12x16x16 | 0.3 mm | 0.011 kg | 16 mm | 16 mm | |

| 29 |

|

IR 12x16x20 | 0.3 mm | 0.014 kg | 16 mm | 20 mm | |

| 30 |

|

IR 12x16x22 | 0.3 mm | 0.015 kg | 16 mm | 22 mm | |

| 31 |

|

IR 14x17x17 | 0.3 mm | 0.0095 kg | 17 mm | 17 mm | |

| 32 |

|

LR 15x18x12.5 | 0.3 mm | 0.0072 kg | 18 mm | 12.5 mm | |

| 33 |

|

IR 15x18x16 | 0.3 mm | 0.0094 kg | 18 mm | 16 mm | |

| 34 |

|

IR 15x18x16.5 | 0.3 mm | 0.0098 kg | 18 mm | 16.5 mm | |

| 35 |

|

IR 15x19x16 | 0.3 mm | 0.013 kg | 19 mm | 16 mm | |

| 36 |

|

IR 15x19x20 | 0.3 mm | 0.016 kg | 19 mm | 20 mm | |

| 37 |

|

IR 15x20x13 | 0.3 mm | 0.014 kg | 20 mm | 13 mm | |

| 38 |

|

IR 15x20x23 | 0.3 mm | 0.024 kg | 20 mm | 23 mm | |

| 39 |

|

IR 17x20x16 | 0.3 mm | 0.011 kg | 20 mm | 16 mm | |

| 40 |

|

IR 17x20x16.5 | 0.3 mm | 0.011 kg | 20 mm | 16.5 mm | |

| 41 |

|

LR17x20x16.5 | 0.3 mm | 0.011 kg | 20 mm | 16.5 mm | |

| 42 |

|

IR 17x20x20 | 0.3 mm | 0.014 kg | 20 mm | 20 mm | |

| 43 |

|

LR 17x20x20.5 | 0.3 mm | 0.014 kg | 20 mm | 20.5 mm | |

| 43 |

|

IR 17x20x20.5 | 0.3 mm | 0.014 kg | 20 mm | 20.5 mm | |

| 44 |

|

IR 17x20x30.5 | 0.3 mm | 0.021 kg | 20 mm | 30.5 mm | |

| 45 |

|

LR 17x20x30.5 | 0.3 mm | 0.021 kg | 20 mm | 30.5 mm | |

| 46 |

|

IR 17x22x13 | 0.3 mm | 0.015 kg | 22 mm | 13 mm | |

| 47 |

|

IR 17x22x16 | 0.3 mm | 0.018 kg | 22 mm | 16 mm | |

| 48 |

|

IR 17x22x23 | 0.3 mm | 0.027 kg | 22 mm | 23 mm | |

| 49 |

|

IR 17x24x20 | 0.6 mm | 0.034 kg | 24 mm | 20 mm | |

| 50 |

|

IR 20x24x16 | 0.3 mm | 0.015 kg | 24 mm | 16 mm | |

| 51 |

|

IR 20x24x20 | 0.3 mm | 0.021 kg | 24 mm | 20 mm | |

| 52 |

|

LR 20x25x12.5 | 0.3 mm | 0.016 kg | 25 mm | 12.5 mm | |

| 53 |

|

LR 20x25x16.5 | 0.3 mm | 0.022 kg | 25 mm | 16.5 mm | |

| 54 |

|

IR 20x25x17 | 0.3 mm | 0.025 kg | 25 mm | 17 mm | |

| 55 |

|

IR 20x25x20 | 0.3 mm | 0.028 kg | 25 mm | 20 mm | |

| 56 |

|

IR 20x25x20.5 | 0.3 mm | 0.027 kg | 25 mm | 20.5 mm | |

| 57 |

|

LR 20x25x20.5 | 0.3 mm | 0.027 kg | 25 mm | 20.5 mm | |

| 58 |

|

IR 20x25x26.5 | 0.3 mm | 0.038 kg | 25 mm | 26.5 mm | |

| 59 |

|

LR 20x25x26.5 | 0.3 mm | 0.038 kg | 25 mm | 26.5 mm | |

| 60 |

|

IR 20x25x30 | 0.3 mm | 0.04 kg | 25 mm | 30 mm | |

| 61 |

|

IR 20x25x38.5 | 0.3 mm | 0.053 kg | 25 mm | 38.5 mm | |

| 62 |

|

IR 20x28x20 | 0.6 mm | 0.045 kg | 28 mm | 20 mm | |

| 63 |

|

IR 22x26x16 | 0.3 mm | 0.018 kg | 26 mm | 16 mm | |

| 64 |

|

IR 22x26x20 | 0.3 mm | 0.023 kg | 26 mm | 20 mm | |

| 65 |

|

IR 22x28x17 | 0.3 mm | 0.03 kg | 28 mm | 17 mm | |

| 66 |

|

IR 22x28x20 | 0.3 mm | 0.035 kg | 28 mm | 20 mm | |

| 67 |

|

IR 22x28x20.5 | 0.3 mm | 0.036 kg | 28 mm | 20.5 mm | |

| 68 |

|

IR 22x28x30 | 0.3 mm | 0.054 kg | 28 mm | 30 mm | |

| 69 |

|

IR 25x29x20 | 0.3 mm | 0.026 kg | 29 mm | 20 mm | |

| 70 |

|

IR 25x29x30 | 0.3 mm | 0.039 kg | 29 mm | 30 mm | |

| 71 |

|

LR 25x30x12.5 | 0.3 mm | 0.02 kg | 30 mm | 12.5 mm | |

| 72 |

|

LR 25x30x16.5 | 0.3 mm | 0.027 kg | 30 mm | 16.5 mm | |

| 73 |

|

IR 25x30x17 | 0.3 mm | 0.027 kg | 30 mm | 17 mm | |

| 74 |

|

IR 25x30x20 | 0.3 mm | 0.033 kg | 30 mm | 20 mm | |

| 75 |

|

IR 25x30x20.5 | 0.3 mm | 0.033 kg | 30 mm | 20.5 mm | |

| 76 |

|

LR 25x30x20.5 | 0.3 mm | 0.033 kg | 30 mm | 20.5 mm | |

| 77 |

|

IR 25x30x26.5 | 0.3 mm | 0.046 kg | 30 mm | 26.5 mm | |

| 78 |

|

LR 25x30x26.5 | 0.3 mm | 0.046 kg | 30 mm | 26.5 mm | |

| 79 |

|

IR 25x30x30 | 0.3 mm | 0.053 kg | 30 mm | 30 mm | |

| 80 |

|

IR 25x30x32 | 0.3 mm | 0.056 kg | 30 mm | 32 mm | |

| 81 |

|

IR 25x30x38.5 | 0.3 mm | 0.065 kg | 30 mm | 38.5 mm | |

| 82 |

|

LR 25x30x38.5 | 0.3 mm | 0.065 kg | 30 mm | 38.5 mm | |

| 83 |

|

IR 25x32x22 | 0.6 mm | 0.053 kg | 32 mm | 22 mm | |

| 84 |

|

IR 28x32x17 | 0.3 mm | 0.025 kg | 32 mm | 17 mm | |

| 85 |

|

IR 28x32x20 | 0.3 mm | 0.029 kg | 32 mm | 20 mm | |

| 86 |

|

IR 28x32x30 | 0.3 mm | 0.044 kg | 32 mm | 30 mm | |

| 87 |

|

LR 30x35x12.5 | 0.3 mm | 0.023 kg | 35 mm | 12.5 mm | |

| 88 |

|

IR 30x35x13 | 0.3 mm | 0.025 kg | 35 mm | 13 mm | |

| 89 |

|

IR 30x35x16 | 0.3 mm | 0.034 kg | 35 mm | 16 mm | |

| 90 |

|

IR 30x35x17 | 0.3 mm | 0.036 kg | 35 mm | 17 mm | |

| 91 |

|

IR 30x35x20 | 0.3 mm | 0.039 kg | 35 mm | 20 mm | |

| 92 |

|

IR 30x35x20.5 | 0.3 mm | 0.04 kg | 35 mm | 20.5 mm | |

| 93 |

|

LR 30x35x20.5 | 0.3 mm | 0.04 kg | 35 mm | 20.5 mm | |

| 94 |

|

IR 30x35x26 | 0.3 mm | 0.05 kg | 35 mm | 26 mm | |

| 95 |

|

IR 30x35x30 | 0.3 mm | 0.059 kg | 35 mm | 30 mm | |

| 96 |

|

IR 30x37x22 | 0.6 mm | 0.062 kg | 37 mm | 22 mm | |

| 97 |

|

IR 32x37x20 | 0.3 mm | 0.042 kg | 37 mm | 20 mm | |

| 98 |

|

IR 32x37x30 | 0.3 mm | 0.062 kg | 37 mm | 30 mm | |

| 99 |

|

IR 32x40x20 | 0.6 mm | 0.068 kg | 40 mm | 20 mm |

Особенности и преимущества внутреннего кольца игольчатого роликового подшипника QIBR

Внутреннее кольцо игольчатого подшипника QIBR решает множество ключевых проблем в различных областях, в основном отраженных в следующих аспектах:

1. Точная обработка

Внутренние кольца игольчатых подшипников обычно изготавливаются с помощью высокоточных процессов обработки, таких как цилиндрическая шлифовка, обработка внутреннего отверстия и т.д., чтобы обеспечить точность размеров и чистоту поверхности, обеспечить более гладкий контакт между игольчатым роликом и внутренним кольцом, и уменьшить потери на трение.

2. Закалка

Для повышения износостойкости и продления срока службы внутреннее кольцо часто подвергается термической обработке (например, закалке и отпуску) для повышения твердости поверхности и улучшения износостойкости.

3. Облегченная конструкция

Поскольку внутреннее кольцо игольчатого подшипника предназначено для обеспечения поддержки и направления, его конструкция обычно имеет облегченную структуру, снижая вес всего подшипника и адаптируясь к требованиям высокой скорости и низкого трения.

4. Износостойкость и усталостная прочность

Материал и метод обработки внутреннего кольца гарантируют, что оно сохраняет хорошие характеристики при длительной эксплуатации. Его износостойкость и усталостная прочность позволяют подшипнику продолжать работать в тяжелых условиях и обеспечивать стабильную работу.

Улучшение характеристик и решение проблемы внутреннего кольца игольчатого роликового подшипника QIBR

1. Покрытие поверхности

Нанесение слоя износостойкого и коррозионностойкого покрытия (например, твердого покрытия, керамического покрытия и т.д.) на поверхность внутреннего кольца позволяет повысить износостойкость, коррозионную стойкость и стойкость к окислению внутреннего кольца, тем самым улучшая его работу в жестких условиях эксплуатации.

2. Азотирование

Азотирование внутреннего кольца позволяет сформировать на его поверхности закаленный слой, улучшить антифрикционные характеристики и снизить износ. Кроме того, азотированный слой обладает высокой коррозионной стойкостью.

3. Прецизионная обработка

Благодаря высокоточным методам обработки, таким как шлифование и сверхточная обработка, улучшается качество поверхности и плоскостность внутреннего кольца, снижается коэффициент трения и повышается устойчивость в условиях высокой скорости и высокой нагрузки.

4. Термообработка

Закалка внутреннего кольца повышает твердость и износостойкость поверхности внутреннего кольца, а также усталостную прочность и ударопрочность. Такая обработка может эффективно продлить срок службы внутреннего кольца.