Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

GCr15

Внутренний диаметр кольца

5-30mm

Наружный диаметр кольца

13-55mm

Вес

0.006-0.38kg

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

Применения

steering systems, suspension systems, and linkage mechanisms

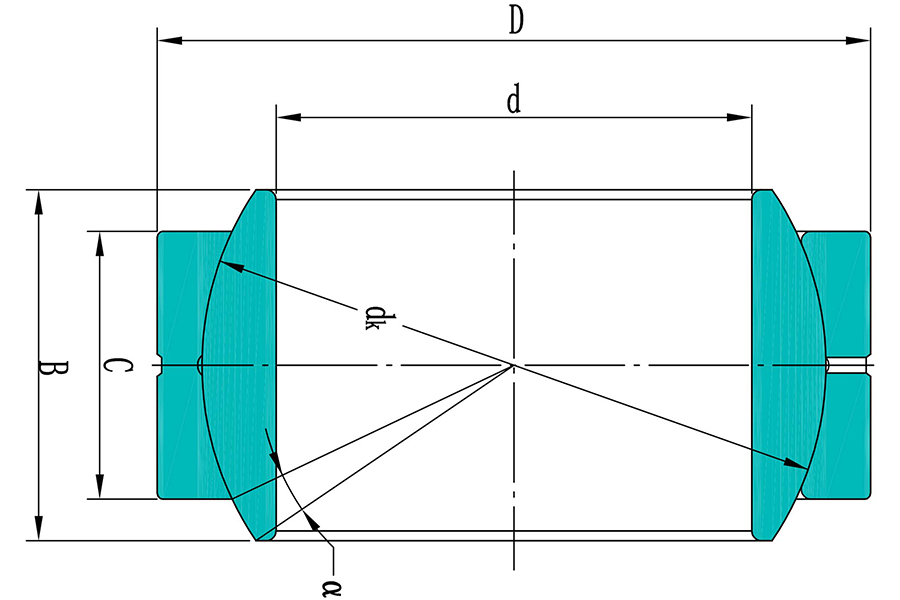

| NO. | Product | Product Number | Наружный диаметр (D) | Вал (d) | Вес | Ширина (B) |

|---|---|---|---|---|---|---|

| 1 |

|

GE5PB | 0.512"/13 mm | 0.197"/5 mm | 0.013 lbs | 0.315"/8 mm |

| 2 |

|

GE6PB | 0.630"/16 mm | 0.236"/6 mm | 0.022 lbs | 0.354"/9 mm |

| 3 |

|

GE8PB | 0.748"/19 mm | 0.315"/8 mm | 0.04 lbs | 0.472"/12 mm |

| 4 |

|

GE10PB | 0.866"/22 mm | 0.394"/10 mm | 0.06 lbs | 0.551"/14 mm |

| 5 |

|

GE12PB | 1.024"/26 mm | 0.472"/12 mm | 0.095 lbs | 0.630"/16 mm |

| 6 |

|

GE14PB | 1.102"/28 mm | 0.551"/14 mm | 0.121 lbs | 0.748"/19 mm |

| 7 |

|

GE16PB | 1.260"/32 mm | 0.630"/16 mm | 0.176 lbs | 0.827"/21 mm |

| 8 |

|

GE18PB | 1.378"/35 mm | 0.709"/18 mm | 0.221 lbs | 0.906"/23 mm |

| 9 |

|

GE20PB | 1.575"/40 mm | 0.787"/20 mm | 0.331 lbs | 0.984"/25 mm |

| 10 |

|

GE22PB | 1.654"/42 mm | 0.866"/22 mm | 0.397 lbs | 1.102"/28 mm |

| 11 |

|

GE25PB | 1.850"/47 mm | 0.984"/25 mm | 0.529 lbs | 1.221"/31 mm |

| 12 |

|

GE30PB | 2.165"/55 mm | 1.181"/30 mm | 0.838 lbs | 1.457"/37 mm |

Особенности и преимущества совместного подшипника QIBR серии GE...PB

Серия QIBR joint bearing GE...PB решает множество ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1. Возможность многонаправленного движения

Шарнирные подшипники QIBR серии GE..PB обычно предназначены для вращения или поворота в нескольких направлениях, поэтому они очень подходят для случаев, требующих углового перемещения. Они могут обеспечить большое относительное угловое перемещение между двумя соединенными деталями.

2. Высокая несущая способность

Шарнирный подшипник QIBR серии GE...PB может выдерживать большие радиальные и осевые нагрузки. Его сферическая конструкция позволяет эффективно рассеивать и переносить большие усилия, поэтому он хорошо работает в условиях высокой интенсивности.

3. Сильная износостойкость

В шарнирных подшипниках QIBR серии GE...PB используются износостойкие материалы, что позволяет эффективно снизить коэффициент трения и повысить износостойкость подшипника. Некоторые композитные шарнирные подшипники даже не требуют смазки и подходят для работы в тяжелых условиях.

4. Простая структура и легкая установка

Подшипник шарнира QIBR серии GE...PB имеет простую структуру и обычно состоит из шарика и гнезда, либо функционирует через скользящие и неподвижные компоненты. Поэтому они относительно просты в установке и не требуют сложного оборудования или сложных технологий.

Улучшение характеристик и решения для сферических подшипников QIBR серии GE...PB

1. Оптимизация смазочного материала: Выберите подходящее смазочное масло или консистентную смазку и сделайте соответствующие добавки и смеси для снижения трения и повышения износостойкости.

2. Оптимизация дорожек качения: Оптимизация геометрии дорожки качения внутреннего и наружного колец, например, повышение точности дорожки качения, улучшение качества поверхности, снижение трения, уменьшение потерь энергии и, таким образом, повышение эффективности работы подшипника.

3. Точность изготовления и контроль допусков: Благодаря прецизионной обработке и строгому контролю допусков, внутренняя структура сферического подшипника становится более гладкой и точной. Точное изготовление может эффективно уменьшить ненужное трение, повысить эффективность работы и уменьшить влияние несбалансированных нагрузок.

4. Увеличение поверхности распределения нагрузки: Оптимизация конструкции контактной поверхности сферического подшипника и увеличение площади распределения нагрузки позволяет снизить локальную концентрацию напряжений, повысить грузоподъемность и продлить срок службы.

Основные области применения совместного подшипника QIBR серии GE...PB

1. Автомобильная промышленность

Система подвески: В системе подвески автомобиля для соединения подвижных частей между колесами и кузовом часто используются шарнирные подшипники, которые могут адаптироваться к различным динамическим нагрузкам и движениям.

Система рулевого управления: Используются в таких компонентах, как шаровые головки рулевого управления и кронштейны шаровых головок, для обеспечения гибкой регулировки направления.

Регулировка сиденья: Шарнирные подшипники используются в механизме регулировки автомобильных сидений, обеспечивая плавное и гибкое перемещение сидений.

2. Аэрокосмическая промышленность

Шасси самолетов: Шарнирные подшипники являются важными соединительными компонентами в шасси самолетов, помогая им выдерживать огромные нагрузки и обеспечивая гибкое движение во время взлета и посадки.

3. Сельскохозяйственная техника

Сельскохозяйственная техника: В сельскохозяйственной технике, такой как тракторы, зерноуборочные комбайны, опрыскиватели и т.д., используются шарнирные подшипники, выдерживающие высокие нагрузки, устойчивые к высоким температурам и коррозии, а также обеспечивающие стабильность оборудования.

Система трансмиссии: Используются в компонентах трансмиссии в сельскохозяйственном оборудовании для переноса и передачи энергии.

4. Инженерная техника

Кран, экскаватор: Подшипники шарниров широко используются в подвижных частях такого оборудования, как краны и экскаваторы, помогая шарнирам и вращающимся частям двигаться гибко и выдерживать сложные рабочие нагрузки.

Forklifts and cranes: In these machines, spherical bearings are used to connect or support rotating, lifting and other moving parts to improve work efficiency.