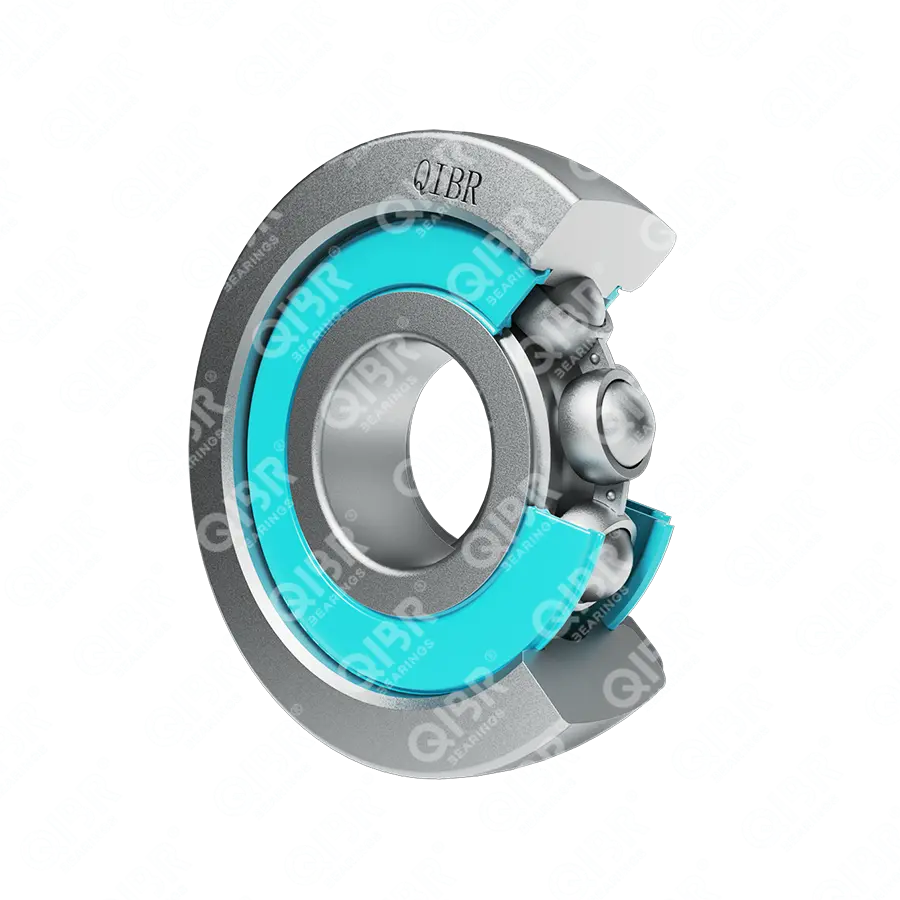

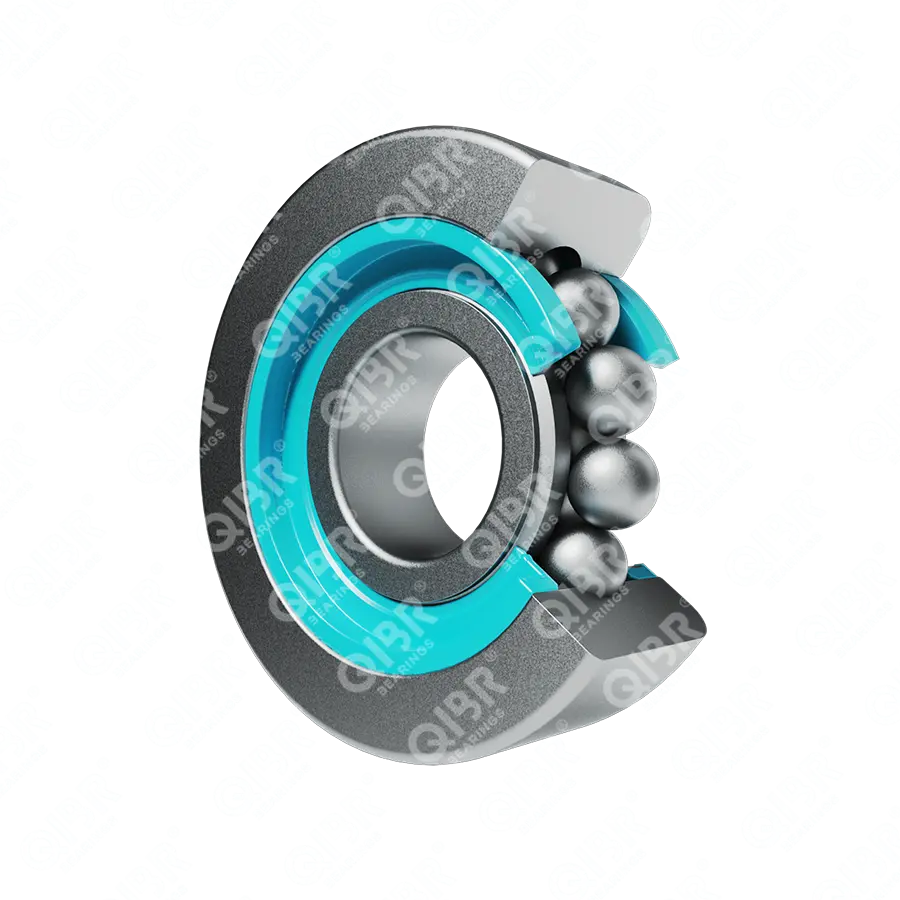

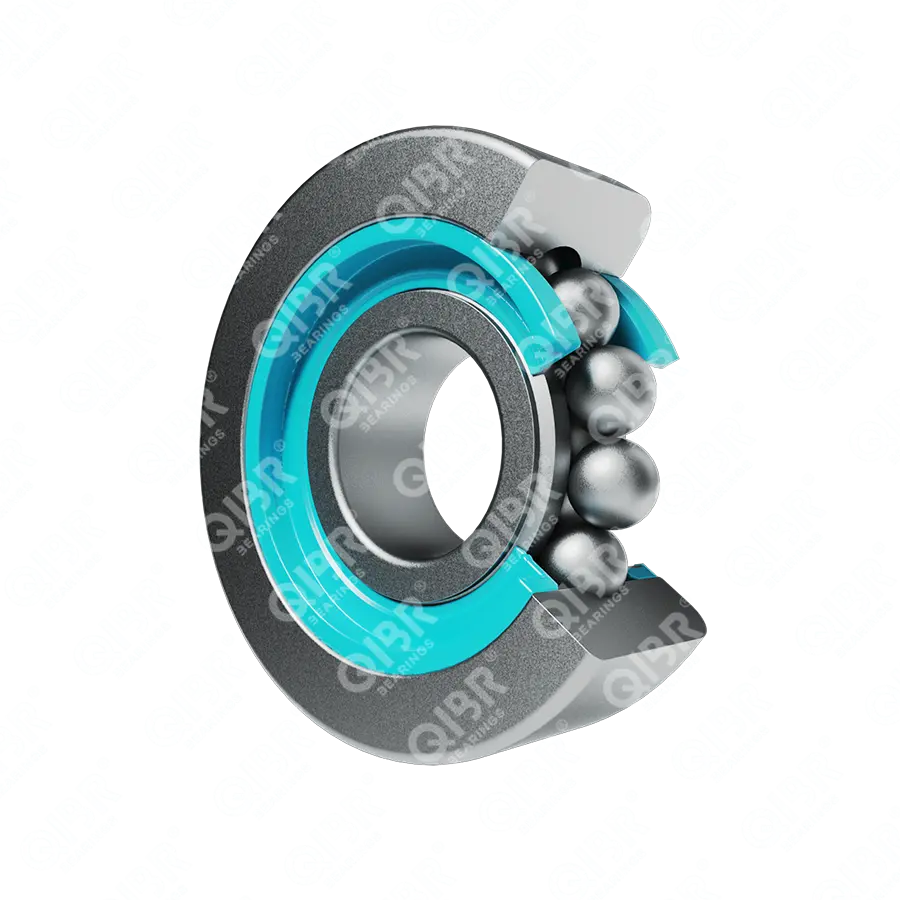

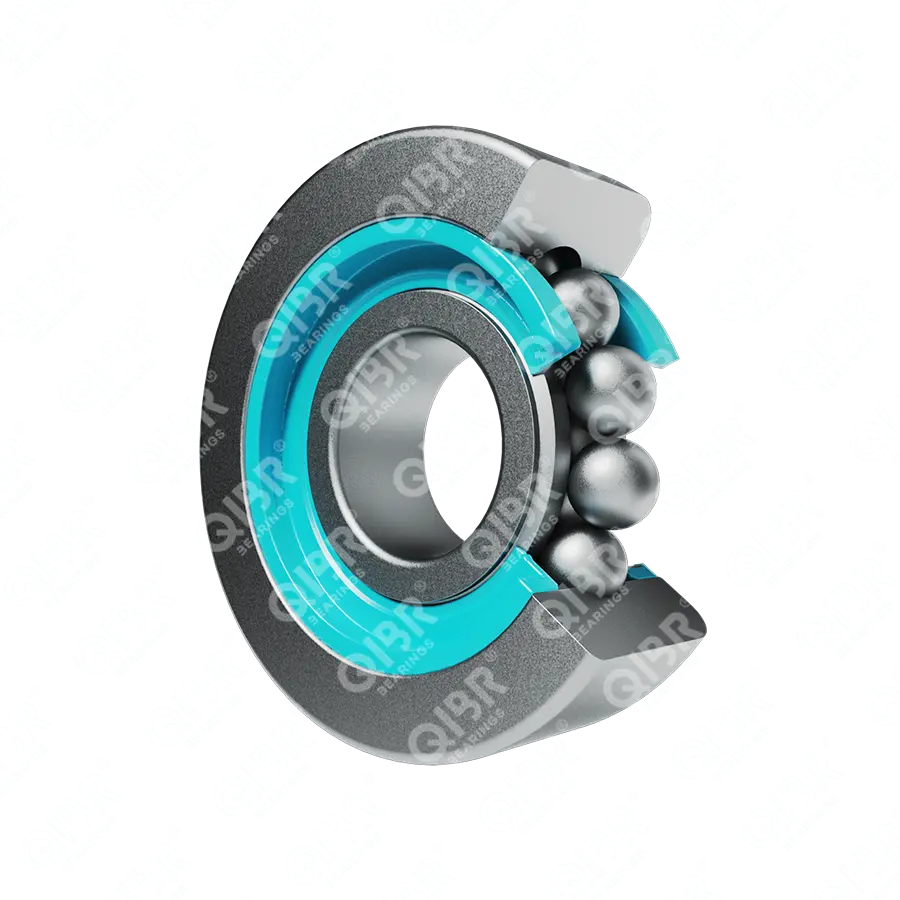

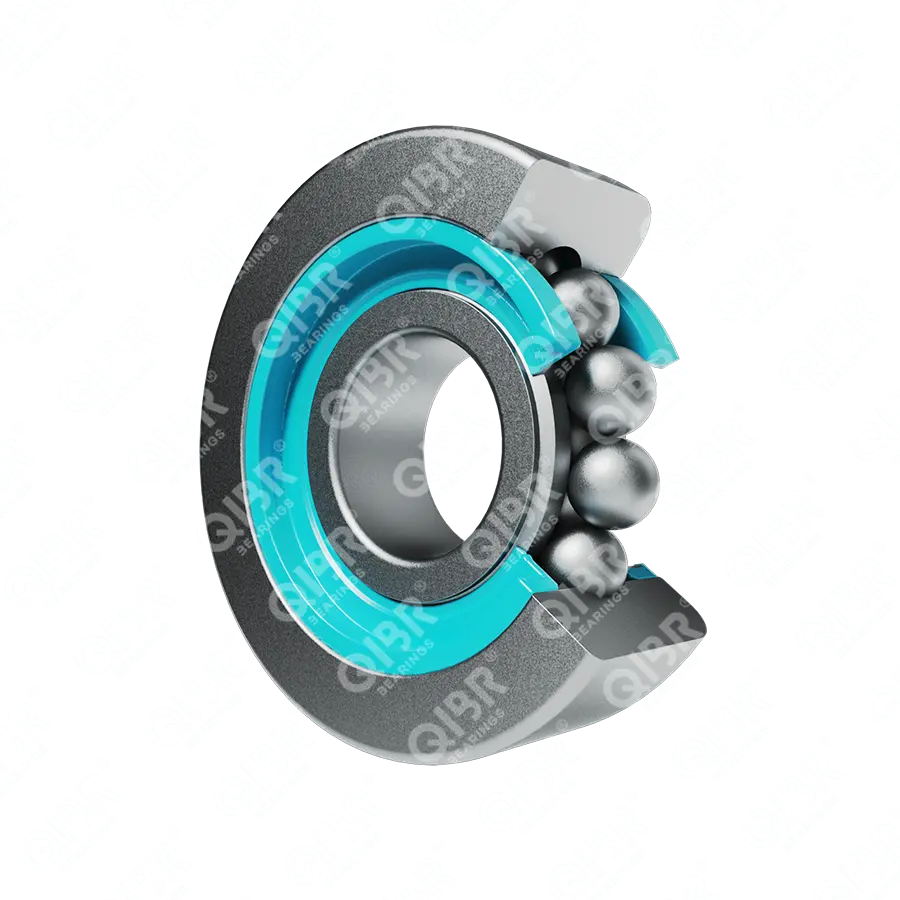

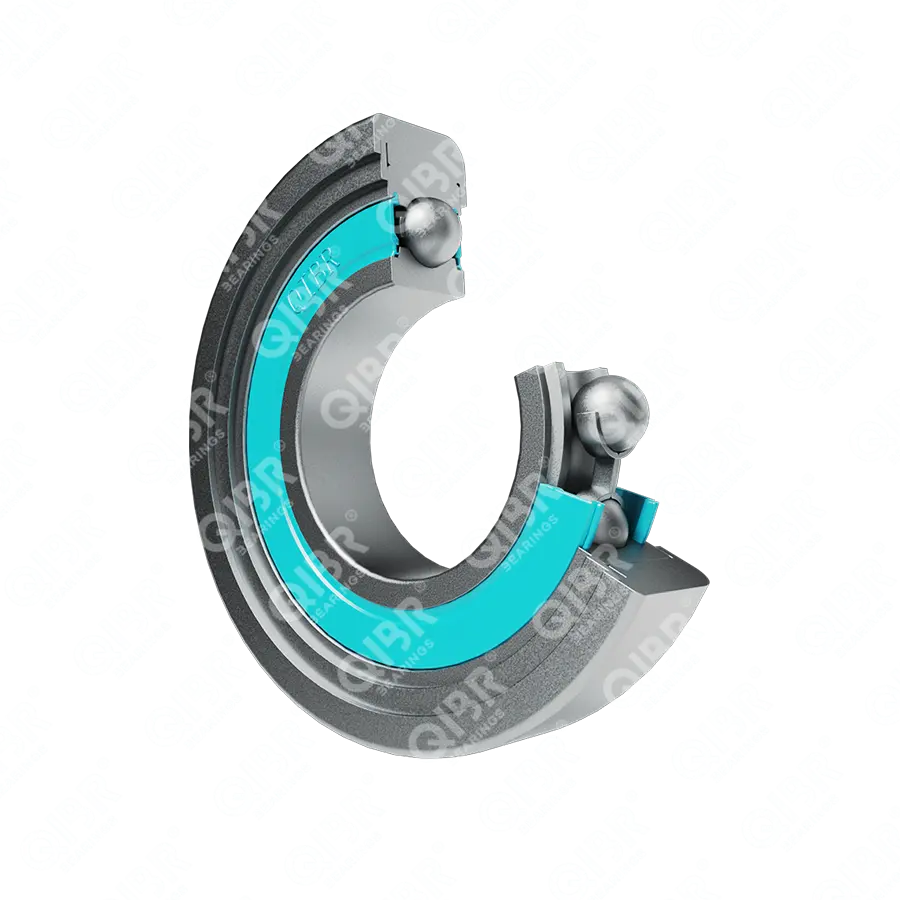

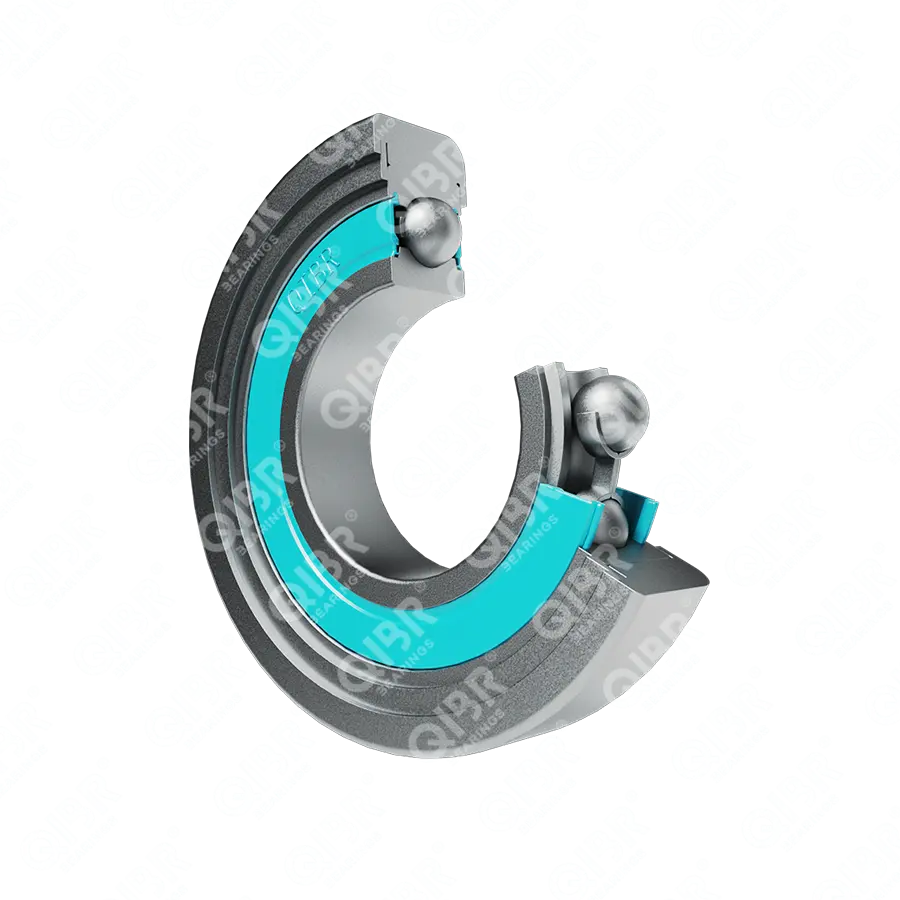

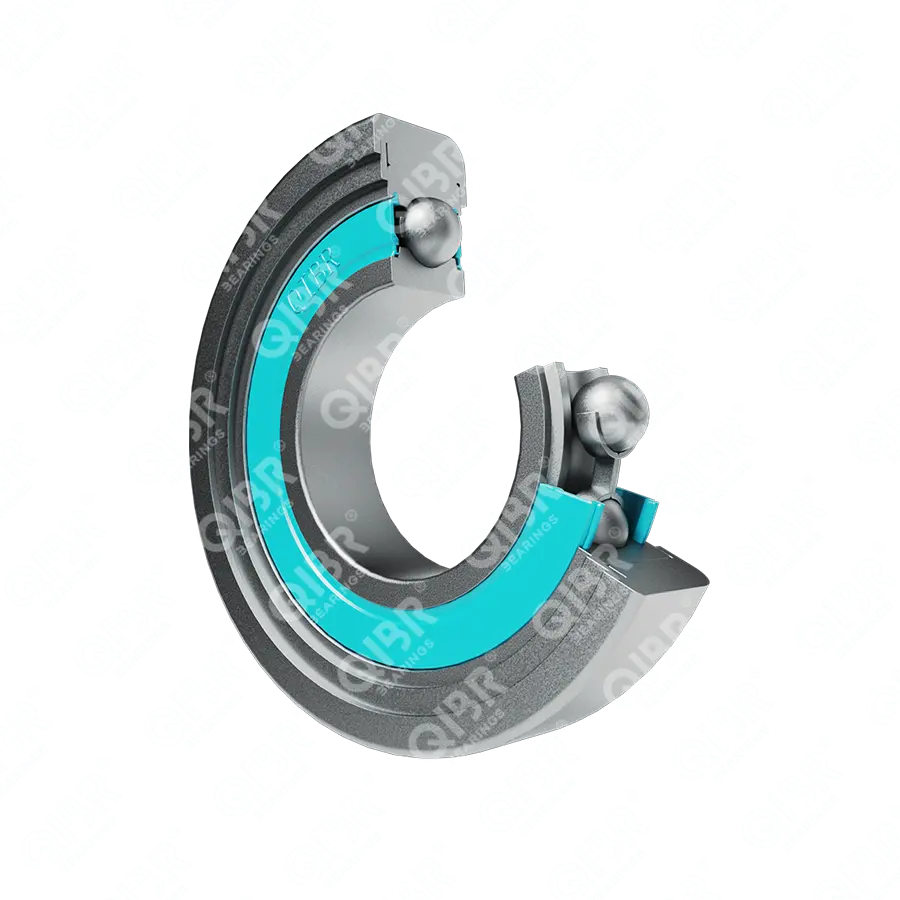

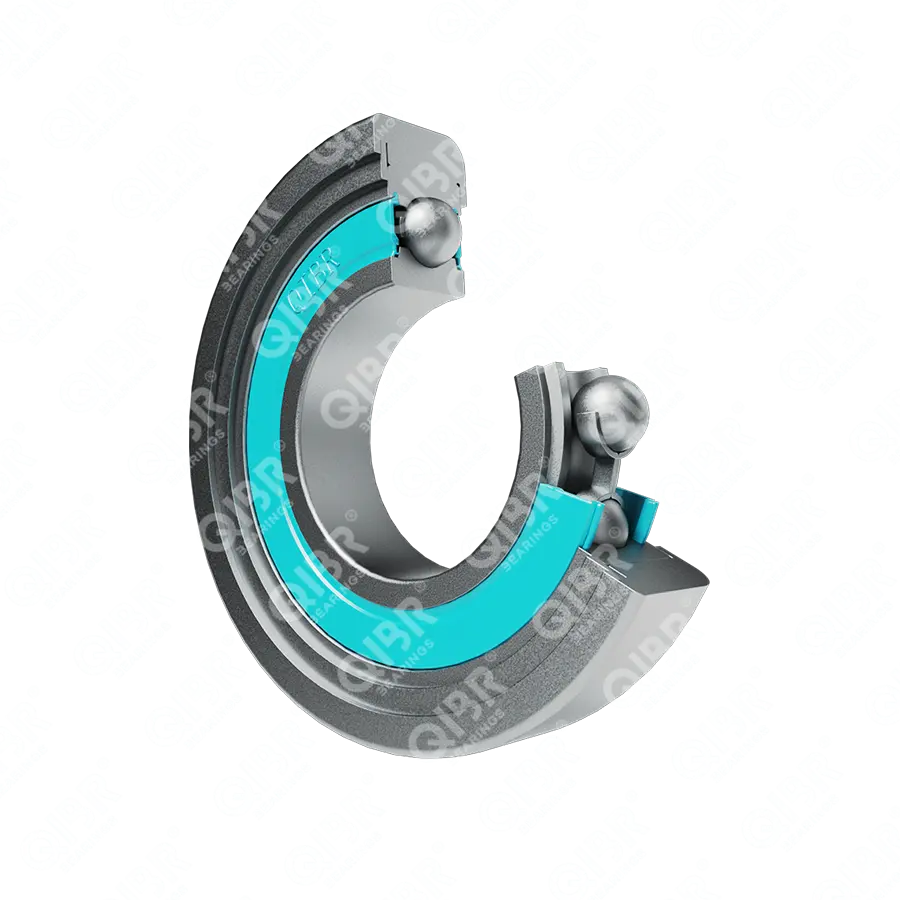

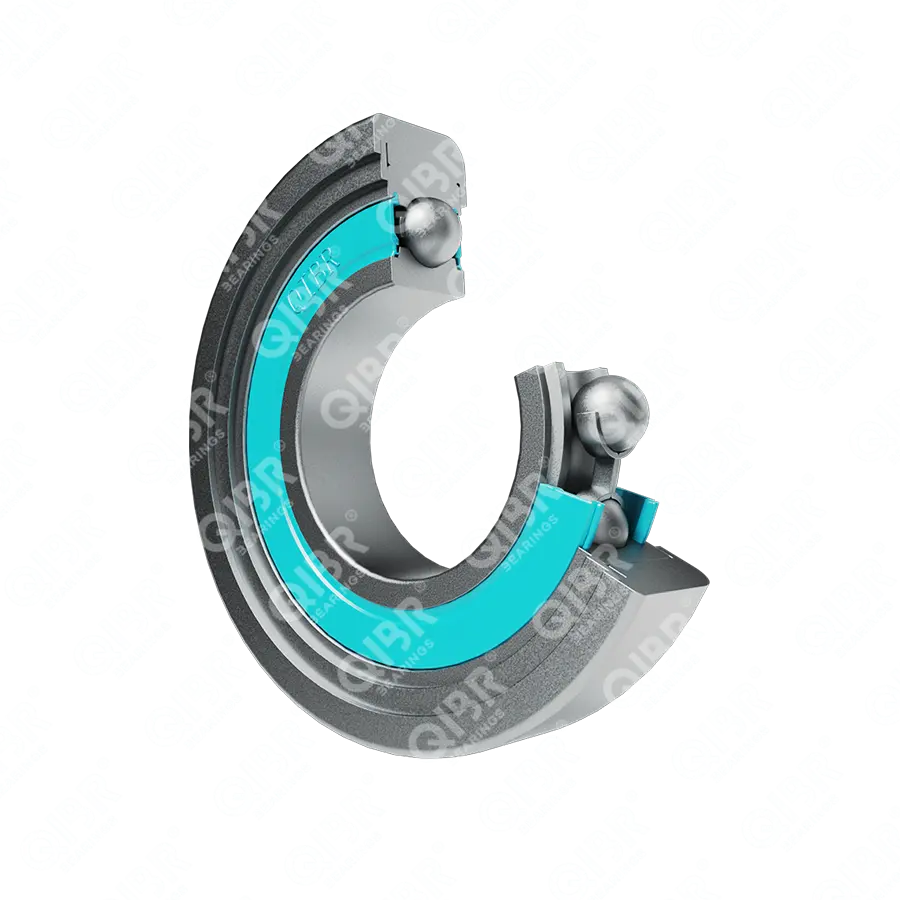

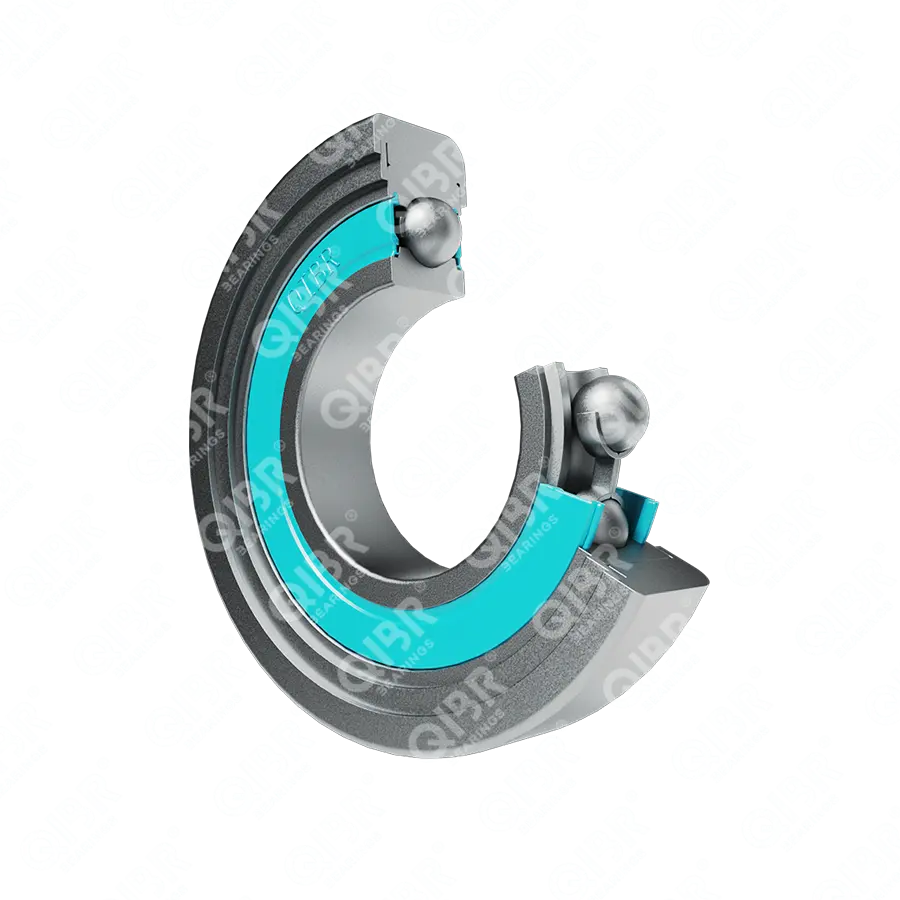

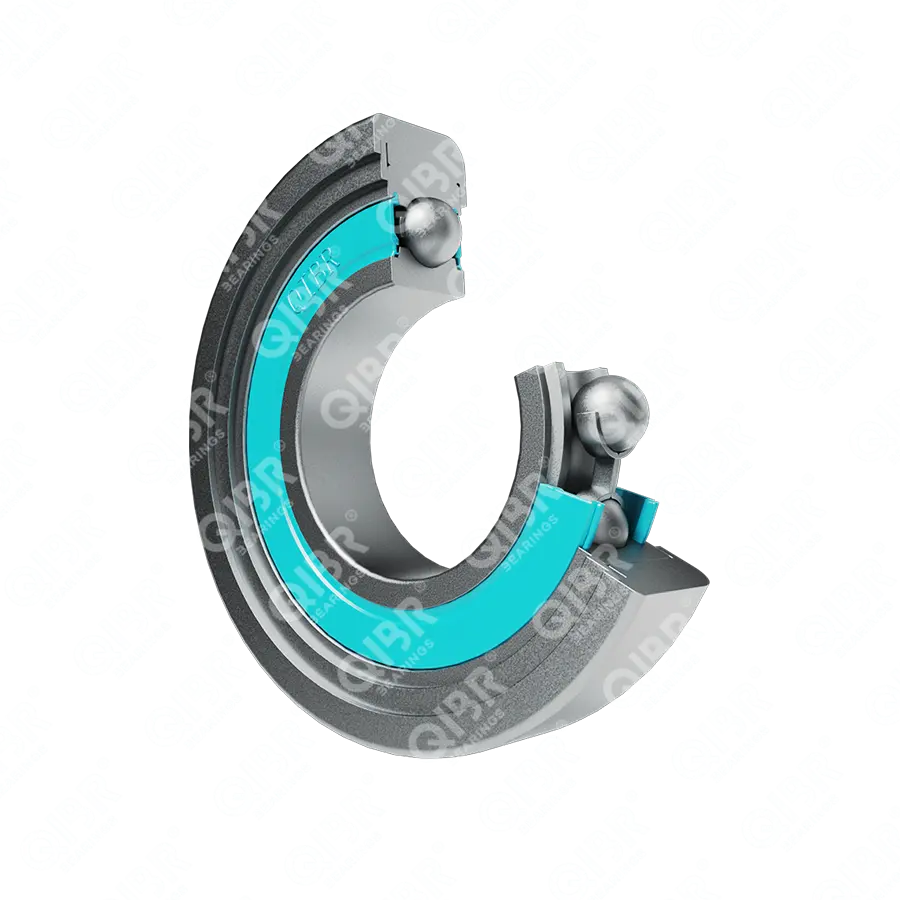

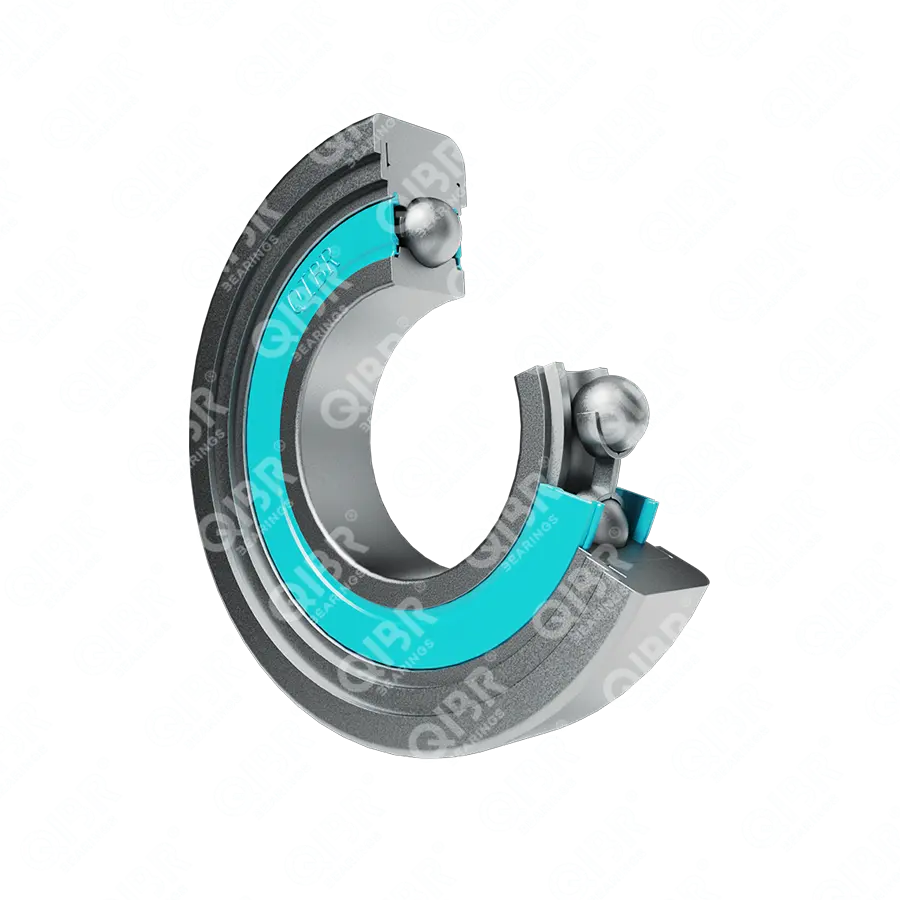

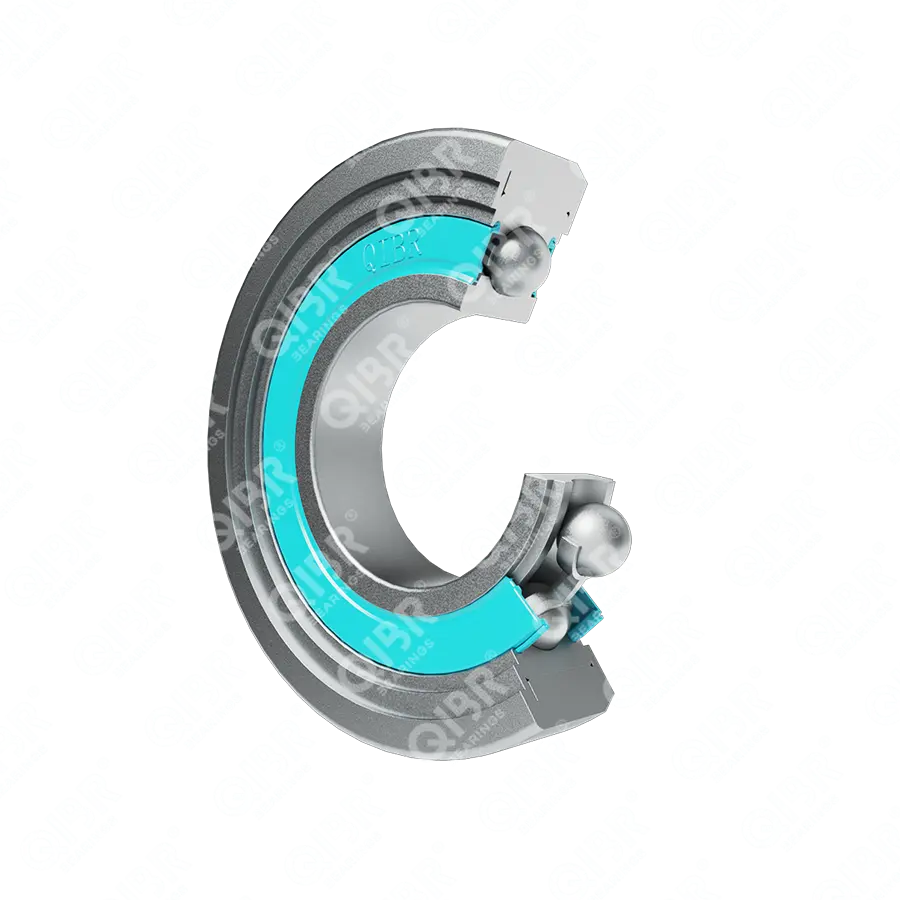

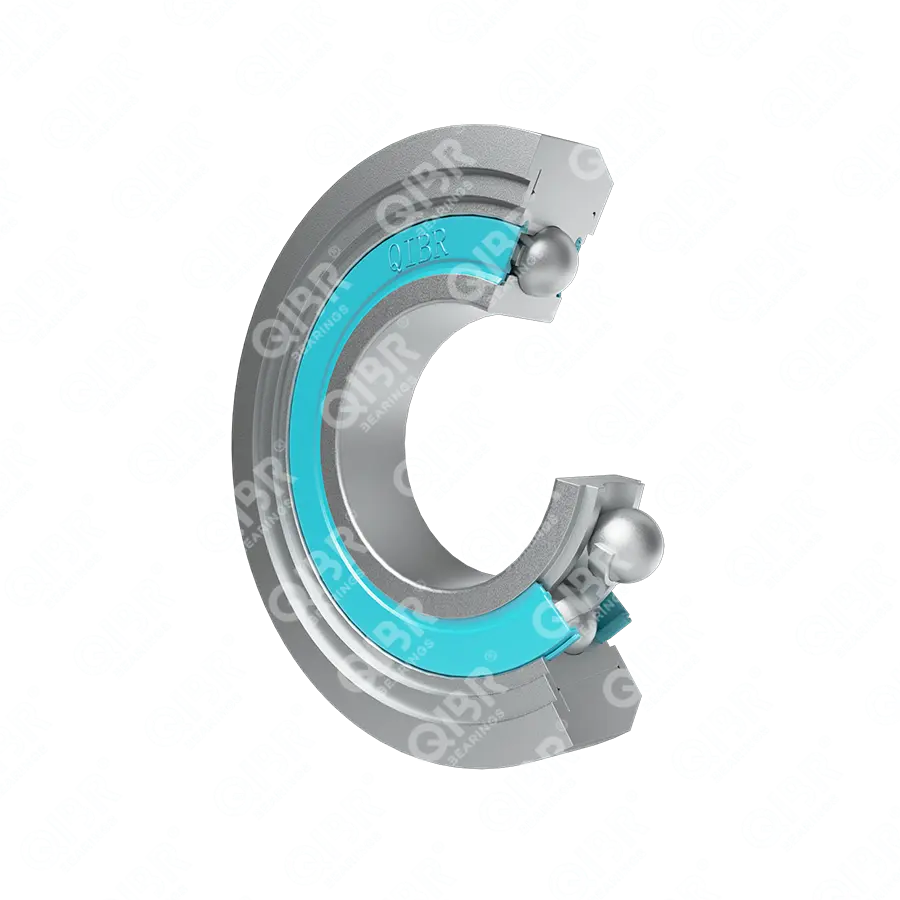

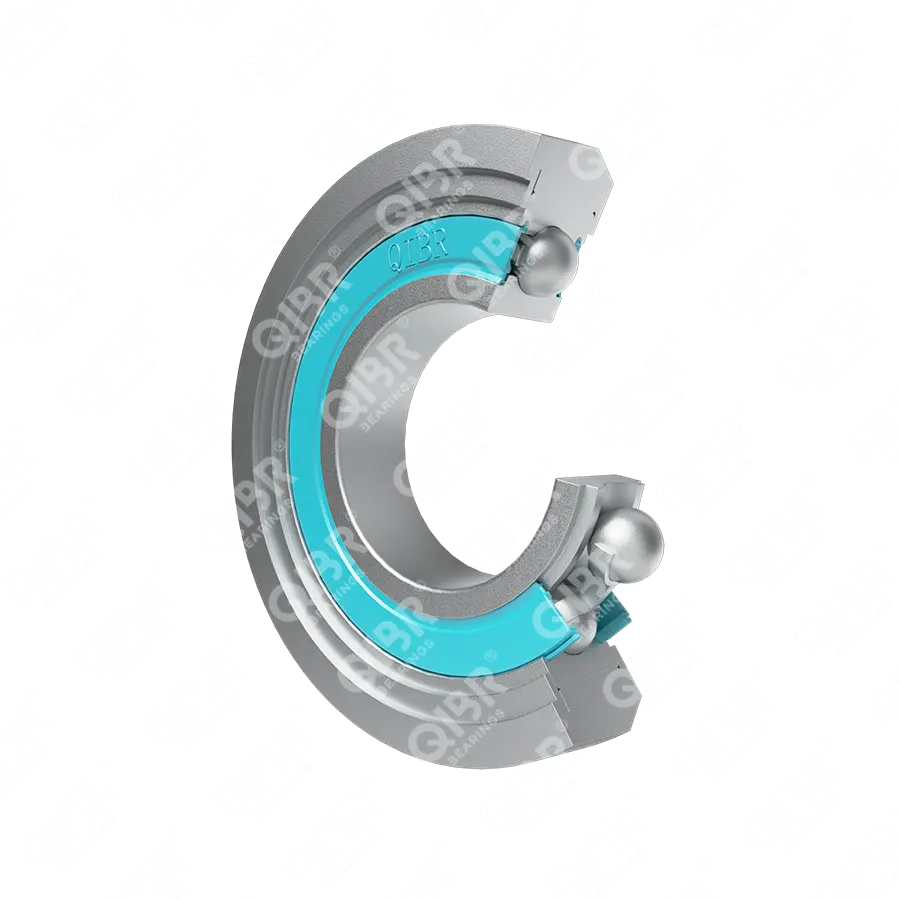

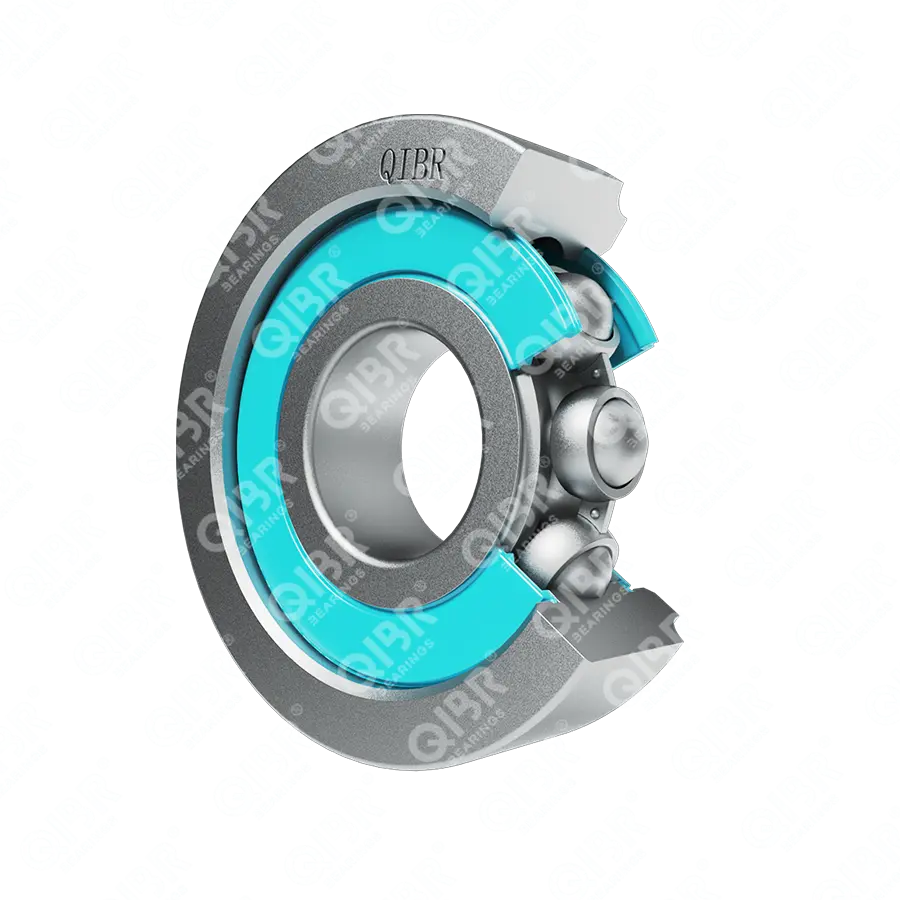

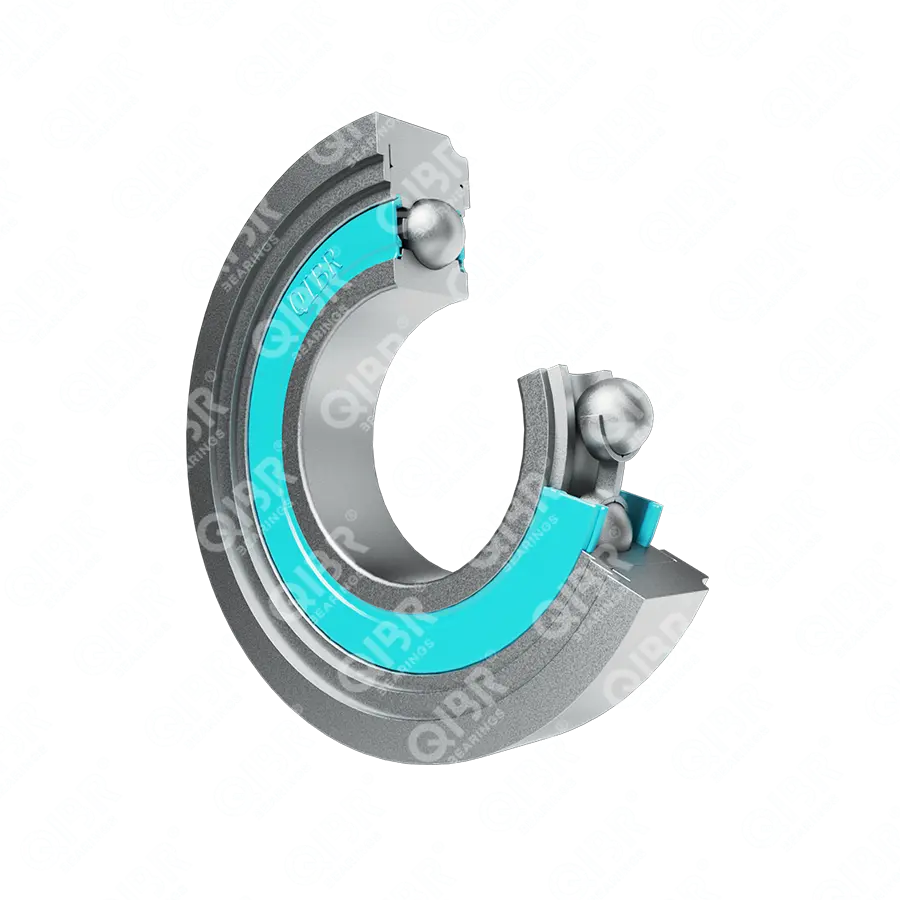

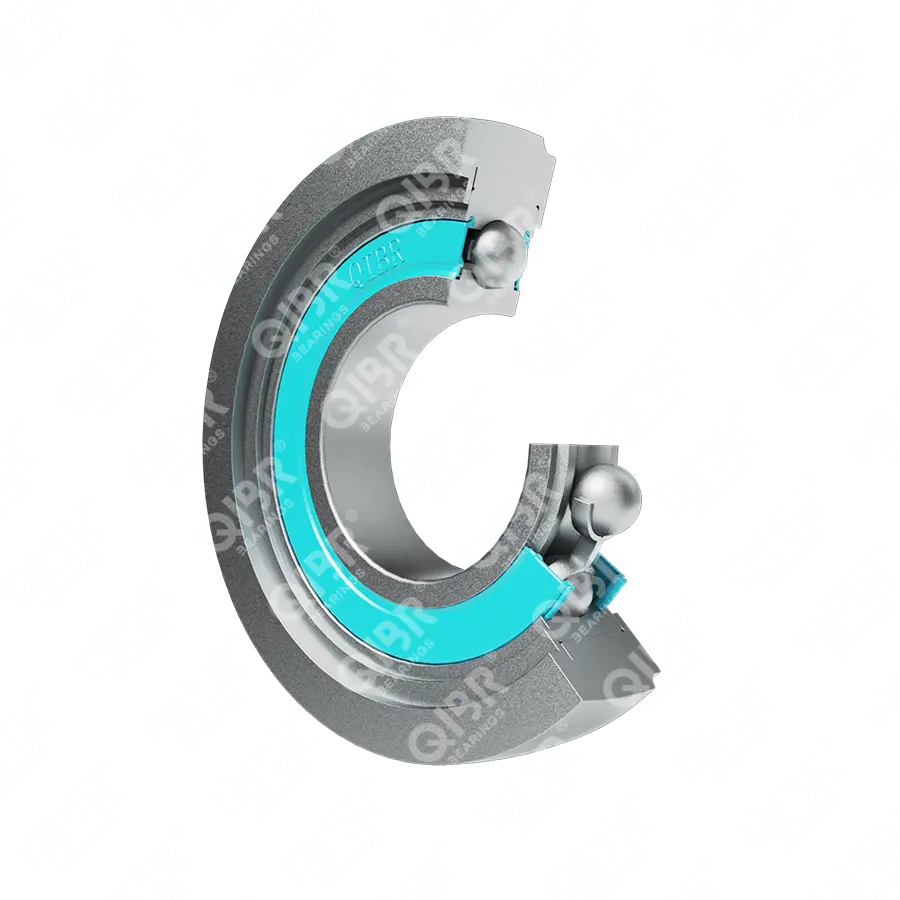

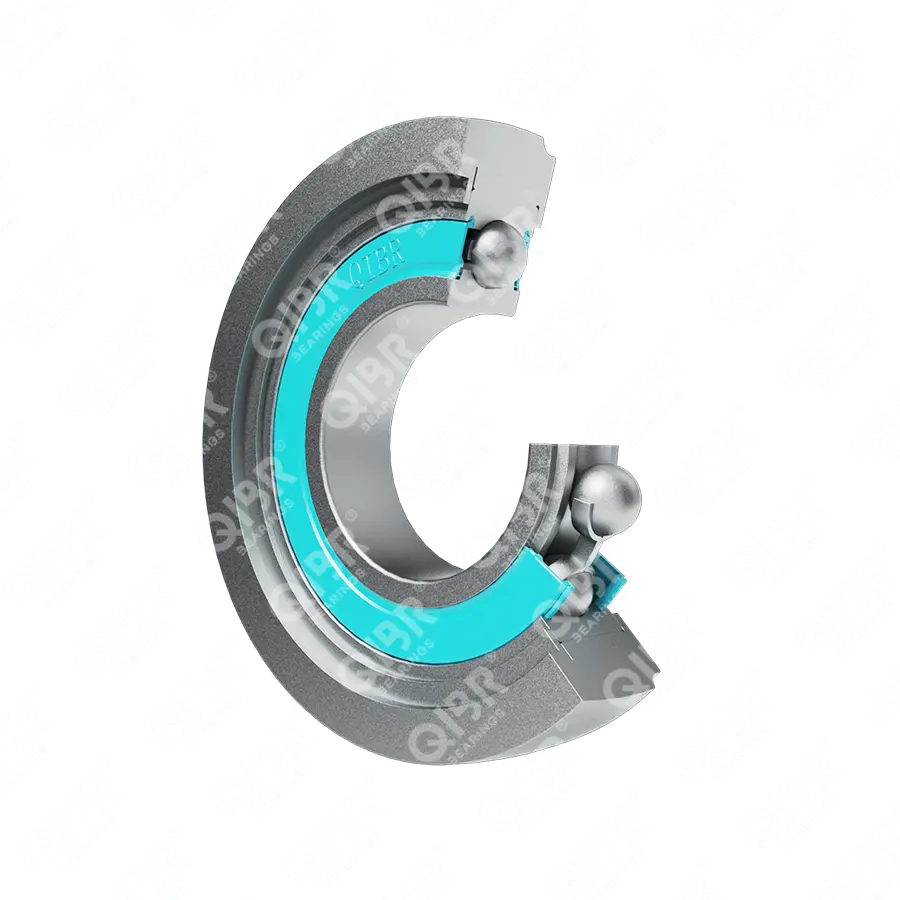

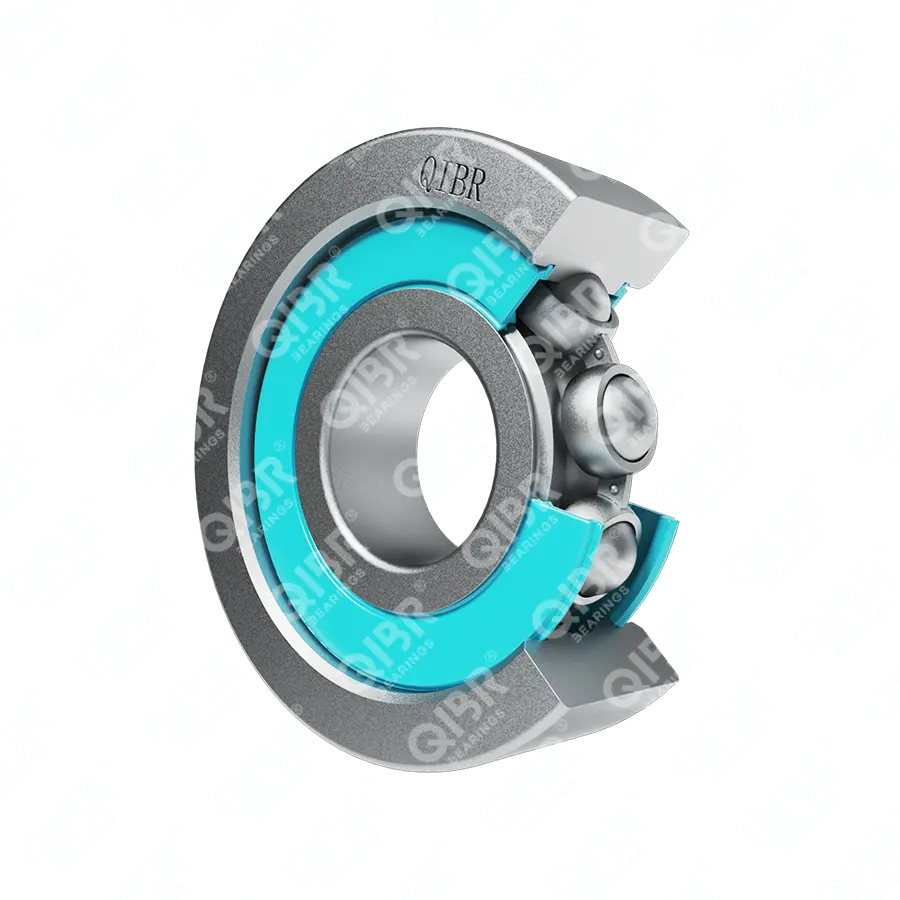

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

GCr15

Внутренний диаметр кольца

0.9843 in.-2.3622 in.

Наружный диаметр кольца

2.5630 in.-7.9600 in.

Общая ширина

0.5680 in.-1.8430 in.

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

Применения

Forklift

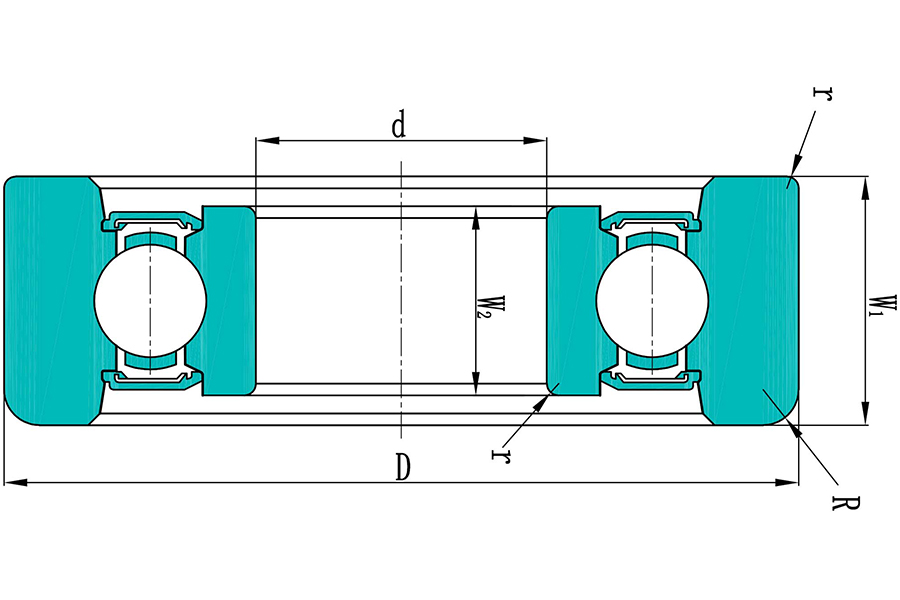

| NO. | Product | Product Number | Отверстие | Округление (r) | Внутреннее кольцо (W2) | Наружный диаметр (D) | Наружное кольцо (W1) | Размер фаски (R) |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

MG-205-FF | 0.9843 inch | 0.0590 inch | 0.5890 inch | 2.5630 inch | 0.8380 inch | 0.2460 inch |

| 2 |

|

MG-206-FFB | 1.1811 inch | 0.0400 inch | 0.6299 inch | 3.0000 inch | 1.0620 inch | 0.0625 inch |

| 3 |

|

MG-206-FFE | 1.1811 inch | 0.0400 inch | 0.6299 inch | 3.0000 inch | 1.1250 inch | 0.0625 inch |

| 4 |

|

MG-305-DD | 0.9843 inch | 0.0400 inch | 0.6293 inch | 3.0000 inch | 1.0000 inch | 0.3000 inch |

| 5 |

|

MG-305-DDE | 0.9843 inch | 0.980 inch | 0.6680 inch | 3.1320 inch | 0.9450 inch | 0.2360 inch |

| 6 |

|

MG-305-DDA | 1.0000 inch | 0.0400 inch | 0.6693 inch | 2.9370 inch | 1.0000 inch | 0.3300 inch |

| 7 |

|

MG-306-DD | 1.1811 inch | 0.0400 inch | 0.7480 inch | 3.5000 inch | 1.0000 inch | 0.3750 inch |

| 8 |

|

MG-306-DDB | 1.1811 inch | 0.0400 inch | 0.7480 inch | 3.2500 inch | 1.0620 inch | 0.3430 inch |

| 9 |

|

MG-306-FF | 1.1811 inch | 0.0400 inch | 0.7480 inch | 3.5000 inch | 1.0000 inch | 0.3450 inch |

| 10 |

|

MG-306-FFB | 1.1811 inch | 0.0400 inch | 0.7480 inch | 3.2500 inch | 1.0620 inch | 0.3430 inch |

| 11 |

|

MG-207-FFJB | 1.3780 inch | 0.0400 inch | 0.6693 inch | 3.7250 inch | 0.9960 inch | 0.3120 inch |

| 12 |

|

MG-307-FFA | 1.3780 inch | 0.0600 inch | 0.8268 inch | 4.0000 inch | 1.1250 inch | 0.3750 inch |

| 13 |

|

MG-307-FFH | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.9900 inch | 1.1250 inch | 0.3750 inch |

| 14 |

|

MG-307-FFHA | 1.3780 inch | 0.0590 inch | 0.8268 inch | 4.0150 inch | 1.1250 inch | 0.3750 inch |

| 15 |

|

MG-307-FFJ | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.7250 inch | 1.0000 inch | 0.3750 inch |

| 16 |

|

MG-307-FFK | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.7250 inch | 1.0000 inch | 0.3750 inch |

| 17 |

|

MG-307-FFWK | 1.3780 inch | 0.0980 inch | 0.8268 inch | 3.7250 inch | 1.1220 inch | 0.2760 inch |

| 18 |

|

MG-307-FFWP | 1.3780 inch | 0.0980 inch | 0.8268 inch | 3.7250 inch | 1.1220 inch | 0.2760 inch |

| 19 |

|

MG-307-FFWR | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.7550 inch | 0.9960 inch | 0.3150 inch |

| 20 |

|

MG-308-FFA | 1.5748 inch | 0.0600 inch | 0.9055 inch | 4.4860 inch | 1.1250 inch | 0.3750 inch |

| 21 |

|

MG-308-FFE | 1.5748 inch | 0.0600 inch | 0.9055 inch | 4.4960 inch | 1.1100 inch | 0.2460 inch |

| 22 |

|

MG-308-FFH | 1.5748 inch | 0.0600 inch | 0.9055 inch | 4.0000 inch | 1.1250 inch | 0.2500 inch |

| 23 |

|

MG-308-FFPA | 1.5748 inch | 0.0980 inch | 0.9055 inch | 4.3390 inch | 1.2800 inch | 0.2760 inch |

| 24 |

|

MG-308-FFPB | 1.5748 inch | 0.0980 inch | 0.9055 inch | 4.3740 inch | 1.2800 inch | 0.2760 inch |

| 25 |

|

MG-308-FFPCN | 1.5748 inch | 0.0900 inch | 0.9055 inch | 4.3180 inch | 1.2600 inch | 0.2760 inch |

| 26 |

|

MG-309-DDA | 1.7717 inch | 0.0600 inch | 0.9843 inch | 5.0030 inch | 1.2500 inch | 0.3125 inch |

| 27 |

|

MG-311-FF | 2.1654 inch | 0.0400 inch | 1.1417 inch | 6.4680 inch | 1.5000 inch | 0.4375 inch |

| 28 |

|

MG-311-FFA | 2.1654 inch | 0.0400 inch | 1.1417 inch | 5.9800 inch | 1.5000 inch | 0.4375 inch |

| 29 |

|

MG-311-ZZ | 2.1654 inch | 0.0800 inch | 1.1417 inch | 6.4680 inch | 1.5000 inch | 0.4375 inch |

| 30 |

|

MG-311-ZZA | 2.1654 inch | 0.0800 inch | 1.1417 inch | 5.9800 inch | 1.5000 inch | 0.4375 inch |

| 31 |

|

MG-308-FFB | 1.5748 inch | 0.0600 inch | 0.9055 inch | 4.0000 inch | 1.1250 inch | 0.3750 inch |

| 32 |

|

MG-305-DDB | 0.9843 inch | 0.0400 inch | 0.6693 inch | 3.0000 inch | 1.0000 inch | 0.2500 inch |

| 33 |

|

MG-307-FFM | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.9930 inch | 1.1250 inch | 0.2400 inch |

| 34 |

|

MG-307-FFP | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.9900 inch | 1.1250 inch | 0.2760 inch |

| 35 |

|

MG-308-FFAB | 1.5748 inch | 0.0590 inch | 0.9055 inch | 4.2786 inch | 1.2200 inch | 0.2360 inch |

| 36 |

|

MG-308-FFAC | 1.5748 inch | 0.0590 inch | 0.9055 inch | 4.3180 inch | 1.2200 inch | 0.2360 inch |

| 37 |

|

MG-308-FFAD | 1.5748 inch | 0.0590 inch | 0.9055 inch | 4.3613 inch | 1.2200 inch | 0.2360 inch |

| 38 |

|

MG-309-DDB | 1.7717 inch | 0.0400 inch | 0.9843 inch | 5.0025 inch | 1.2500 inch | 0.3125 inch |

| 39 |

|

MG-309-DDBA | 1.7717 inch | 0.0600 inch | 0.9843 inch | 5.0340 inch | 1.2500 inch | 0.3125 inch |

| 40 |

|

MG-307-LL | 1.3780 inch | 0.0600 inch | 0.7874 inch | 3.6170 inch | 1.2225 inch | 0.3100 inch |

| 41 |

|

MG-307-LLA | 1.3780 inch | 0.0600 inch | 0.7874 inch | 3.2230 inch | 1.2225 inch | 0.3100 inch |

| 42 |

|

MG-307-LLB | 1.3780 inch | 0.0600 inch | 0.7874 inch | 3.2300 inch | 1.2225 inch | 0.3100 inch |

| 43 |

|

MG-307-LLH | 1.3780 inch | 0.0600 inch | 0.7874 inch | 3.6240 inch | 1.2250 inch | 0.3100 inch |

| 45 |

|

MG-307-FFZ | 1.3780 inch | 0.0600 inch | 0.8268 inch | 4.0000 inch | 1.1250 inch | 0.3750 inch |

| 46 |

|

MG-208-FFH | 1.5748 inch | 0.0400 inch | 0.8280 inch | 3.7400 inch | 1.1350 inch | 0.3120 inch |

| 47 |

|

MG-208-FFJ | 1.5748 inch | 0.0400 inch | 0.8280 inch | 4.0160 inch | 1.1350 inch | 0.3120 inch |

| 48 |

|

MG-208-FFK | 1.5748 inch | 0.0400 inch | 0.8280 inch | 3.9900 inch | 1.1350 inch | 0.3120 inch |

| 49 |

|

MG-209-FFA | 1.5748 inch | 0.0400 inch | 0.8280 inch | 3.9900 inch | 1.1350 inch | 0.3120 inch |

| 50 |

|

MG-310-FFA | 1.9685 inch | 0.0600 inch | 0.9940 inch | 4.9950 inch | 1.1900 inch | 0.3120 inch |

| 51 |

|

MG-206-FFH | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1300 inch | 1.1250 inch | 0.2500 inch |

| 52 |

|

MG-206-FFHA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1300 inch | 1.1250 inch | 0.2500 inch |

| 53 |

|

MG-206-FFK | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4000 inch | 1.1250 inch | 0.2500 inch |

| 54 |

|

MG-206-FFKA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4000 inch | 1.1250 inch | 0.2500 inch |

| 55 |

|

MG-206-FFP | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4700 inch | 1.1520 inch | 0.2360 inch |

| 56 |

|

MG-206-FFPA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4855 inch | 1.1250 inch | 0.2360 inch |

| 58 |

|

MG-206-FFU | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1940 inch | 1.1520 inch | 0.2360 inch |

| 59 |

|

MG-206-FFUA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.2140 inch | 1.1520 inch | 0.2360 inch |

| 60 |

|

MG-206-FFPB | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.5055 inch | 1.1520 inch | 0.2360 inch |

| 61 |

|

MG-206-FFU | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1940 inch | 1.1250 inch | 0.2360 inch |

| 63 |

|

MG-206-FFUB | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.2340 inch | 1.1520 inch | 0.2360 inch |

| 64 |

|

MG-206-FFW | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4140 inch | 1.1250 inch | 0.1900 inch |

| 65 |

|

MG-206-FFWA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4440 inch | 1.1250 inch | 0.1900 inch |

| 66 |

|

MG-206-FFWB | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.4740 inch | 1.1250 inch | 0.1900 inch |

| 67 |

|

MG-206-FFZ | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1390 inch | 1.1250 inch | 0.1900 inch |

| 68 |

|

MG-206-FFZA | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1690 inch | 1.1250 inch | 0.1900 inch |

| 69 |

|

MG-206-FFZB | 1.1811 inch | 0.0400 inch | 0.6530 inch | 3.1990 inch | 1.1250 inch | 0.1900 inch |

| 70 |

|

MG-207-FFJA | 1.3780 inch | 0.0400 inch | 0.7860 inch | 3.6190 inch | 1.2550 inch | 0.3100 inch |

| 71 |

|

MG-207-FFQA | 1.3780 inch | 0.0400 inch | 0.7860 inch | 4.3730 inch | 1.1920 inch | 0.3100 inch |

| 72 |

|

MG-207-FFQB | 1.3780 inch | 0.0400 inch | 0.7874 inch | 3.9620 inch | 1.1920 inch | 0.3100 inch |

| 73 |

|

MG-207-FFQH | 1.3780 inch | 0.0400 inch | 0.7874 inch | 4.3780 inch | 1.1850 inch | 0.3100 inch |

| 74 |

|

MG-207-FFQJ | 1.3780 inch | 0.0400 inch | 0.7874 inch | 4.3790 inch | 1.1850 inch | 0.3100 inch |

| 75 |

|

MG-207-FFU | 1.3780 inch | 0.0600 inch | 0..8268 inch | 3.9900 inch | 1.1250 inch | 0.2760 inch |

| 76 |

|

MG-207-FFQM | 1.3780 inch | 0.0400 inch | 0.7874 inch | 4.3910 inch | 1.1850 inch | 0.3100 inch |

| 77 |

|

MG-207-FFUA | 1.3780 inch | 0.0400 inch | 0.7874 inch | 3.6170 inch | 1.2250 inch | 0.3100 inch |

| 78 |

|

MG-207-FFUB | 1.3780 inch | 0.0400 inch | 0.7874 inch | 3.6090 inch | 1.2250 inch | 0.3100 inch |

| 79 |

|

MG-207-FFWA | 1.3780 inch | 0.0400 inch | 0.7874 inch | 3.2230 inch | 1.2250 inch | 0.3100 inch |

| 80 |

|

MG-308-FFU | 1.5748 inch | 0.0600 inch | 0.8500 inch | 4.3780 inch | 1.2690 inch | 0.3100 inch |

| 81 |

|

MG-308-FFUA | 1.5748 inch | 0.0600 inch | 0.8500 inch | 4.3930 inch | 1.2690 inch | 0.3100 inch |

| 82 |

|

MG-308-FFUB | 1.5748 inch | 0.0600 inch | 0.8500 inch | 4.4380 inch | 1.2690 inch | 0.3100 inch |

| 83 |

|

MG-206-FF | 1.1811 inch | 0.0400 inch | 0.7712 inch | 3.2350 inch | 1.0000 inch | - |

| 84 |

|

MG-206-FFA | 1.1811 inch | 0.0400 inch | 0.7712 inch | 3.2000 inch | 1.0000 inch | - |

| 85 |

|

MG-208-FFA | 1.5748 inch | 0.0400 inch | 0.7712 inch | 3.9700 inch | 1.0000 inch | - |

| 86 |

|

MG-208-FFB | 1.5748 inch | 0.0400 inch | 0.7087 inch | 3.9420 inch | 1.0000 inch | - |

| 87 |

|

MG-208-FFM | 1.5748 inch | 0.0400 inch | 0.7712 inch | 4.0000 inch | 1.0000 inch | - |

| 88 |

|

MG-309-DDE | 1.7717 inch | 0.0600 inch | 0.9843 inch | 4.9420 inch | 1.5150 inch | - |

| 89 |

|

MG-307-FFQ | 1.3780 inch | 0.0400 inch | - | 4.4900 inch | 1.2550 inch | 0.2550 inch |

| 90 |

|

MG-307-FFQB | 1.3780 inch | 0.0400 inch | - | 4.4900 inch | 1.2550 inch | 0.1250 inch |

| 91 |

|

MG-206-FFM | 1.1811 inch | 0.0400 inch | 0.7712 inch | 3.2000 inch | 1.0000 inch | - |

| 92 |

|

MG-208-FFE | 1.5748 inch | 0.0400 inch | 0.7712 inch | 3.9700 inch | 1.0000 inch | - |

| 93 |

|

MG-307-FFE | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.9900 inch | 1.1250 inch | - |

| 94 |

|

MG-207-FFM | 1.3780 inch | 0.0400 inch | 0.8268 inch | 3.9910 inch | 1.1250 inch | - |

| 95 |

|

MG-207-FFH | 1.3780 inch | 0.0400 inch | 0.8268 inch | 3.5920 inch | 1.2550 inch | - |

| 96 |

|

MG-207-FFJ | 1.3780 inch | 0.0400 inch | 0.7874 inch | 3.5920 inch | 1.2550 inch | - |

| 97 |

|

MG-207-FFK | 1.3780 inch | 0.0400 inch | 0.8268 inch | 4.3820 inch | 1.1920 inch | - |

| 98 |

|

MG-207-FFP | 1.3780 inch | 0.0400 inch | 0.8850 inch | 3.5920 inch | 1.2550 inch | - |

| 99 |

|

MG-207-FFQ | 1.3780 inch | 0.0400 inch | 0.7874 inch | 4.3730 inch | 1.1920 inch | - |

| 100 |

|

MG-207-FFQC | 1.3780 inch | 0.0400 inch | 0.7874 inch | 4.9720 inch | 1.1870 inch | - |

| 102 |

|

MG-207-FFB | 1.3780 inch | 0.0400 inch | 0.6693 inch | 3.4800 inch | 1.2550 inch | 0.0625 inch |

| 103 |

|

MG-307-FFB | 1.3780 inch | 0.0600 inch | 0.8268 inch | 3.9800 inch | 1.2550 inch | 0.1250 inch |

| 104 |

|

MG-209-DD | 1.7717 inch | 0.0800 inch | 0.7480 inch | 3.9750 inch | 1.1210 inch | 0.1250 inch |

Особенности и преимущества роликовых подшипников направляющих мачт

Роликовые подшипники направляющих мачт решают несколько ключевых проблем в различных областях, в основном отраженных в следующих аспектах:

1. Высокая несущая способность

Вилочные погрузчики обычно используются для транспортировки тяжелых грузов, поэтому направляющие роликовые подшипники должны обладать высокой несущей способностью. Они должны поддерживать стабильную работу вилочного погрузчика под нагрузкой. Для поддержания стабильности и долговечности при больших нагрузках подшипники часто проектируются с высокой устойчивостью к нагрузкам, например, усиленные шариковые или роликовые подшипники большого диаметра.

2. Износостойкость

Поскольку вилочные погрузчики испытывают значительное трение и давление во время работы, основные роликовые подшипники должны обладать высокой износостойкостью. Материал подшипника обычно изготавливается из высокопрочной легированной стали или других износостойких материалов, обеспечивающих отличную износостойкость и эффективно снижающих износ, вызванный трением, тем самым продлевая срок службы.

3. Низкий уровень шума и высокая стабильность

При ежедневной эксплуатации вилочного погрузчика шум и вибрация подшипников должны быть сведены к минимуму для обеспечения бесперебойной работы. Конструкция основных роликовых подшипников обычно сосредоточена на снижении шума и вибрации, использовании прецизионно обработанных тел качения и систем смазки для обеспечения тихой и плавной работы вилочного погрузчика.

4. Адаптация к сложным условиям работы

Вилочные погрузчики часто работают в сложных условиях, таких как склады, строительные площадки и грузовые терминалы. В этих местах может быть неровный пол, и погрузчикам приходится постоянно поворачивать или резко останавливаться. Поэтому главные роликовые подшипники должны быть способны адаптироваться к этим сложным условиям, обеспечивая надежную опору и устойчивость для бесперебойной работы погрузчика.

Улучшение характеристик и решения для роликовых подшипников направляющих мачт

1. Оптимизация смазки

Выбор подходящего смазочного масла или консистентной смазки, а также их правильное добавление и смешивание могут снизить трение и повысить износостойкость. Использование синтетических смазочных материалов или наносмазок может значительно повысить эффективность и срок службы подшипника.

2. Оптимизация дорожки качения

Оптимизация геометрии дорожек качения внутреннего и наружного колец, например, повышение точности дорожек качения и улучшение качества поверхности, снижает трение, минимизирует потери энергии и повышает эффективность подшипника.

3. Усиленная структура уплотнения

Разработка эффективной системы уплотнения для предотвращения попадания в подшипник пыли, грязи, влаги и других внешних загрязнений. Хорошая конструкция уплотнения помогает поддерживать подшипник в чистоте и продлевает срок его службы.

4. Коррозионностойкая конструкция

Для сложных условий эксплуатации (например, в морской или химической среде) использование нержавеющей стали, коррозионностойких покрытий или методов обработки поверхности может повысить устойчивость подшипника к коррозии.

Основные области применения роликовых подшипников направляющих мачт

1. Опора главного колеса вилочного погрузчика

Роликовые подшипники направляющих мачт обычно устанавливаются во вращающейся части главного колеса, поддерживая свободное вращение главного колеса в горизонтальной плоскости, уменьшая трение и повышая эффективность работы. Главное колесо несет на себе вес вилочного погрузчика и отвечает за движение по земле, поэтому использование подшипников в этой области улучшает управляемость и долговечность погрузчика.

2. Применение гидравлической системы

В некоторых конструкциях вилочных погрузчиков роликовые подшипники направляющих мачт могут также использоваться в гидравлических устройствах, подъемных рычагах и системах перемещения вилочного захвата, обеспечивая стабильность и точное управление этими компонентами.

3. Тяжелые условия работы

Вилочные погрузчики в основном используются в промышленных, складских и логистических условиях с большими нагрузками. Роликовые подшипники направляющих мачт должны выдерживать значительное давление и трение, что делает их пригодными для различных операций наземного транспорта, таких как обработка грузов, штабелирование и погрузка/разгрузка.

4. Места высокочастотного использования

Роликовые подшипники направляющих мачт обладают отличной прочностью на сжатие, устойчивостью к высоким температурам и длительным сроком службы, что делает их идеальными для использования в условиях высокочастотной эксплуатации.