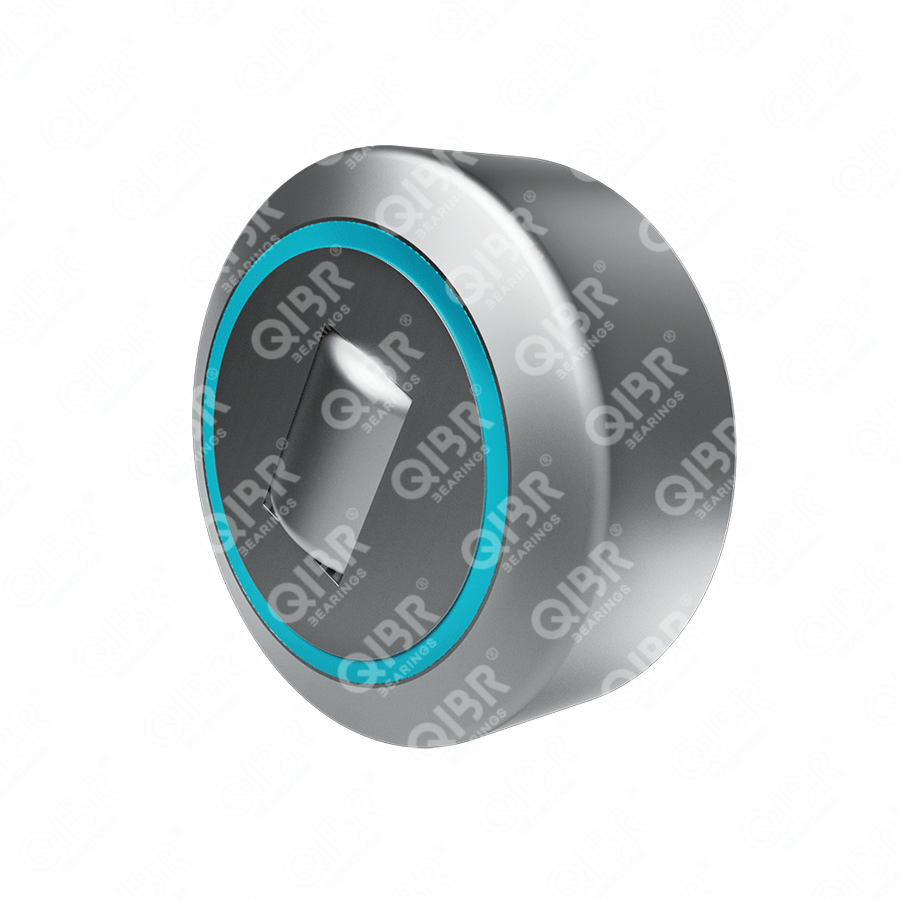

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

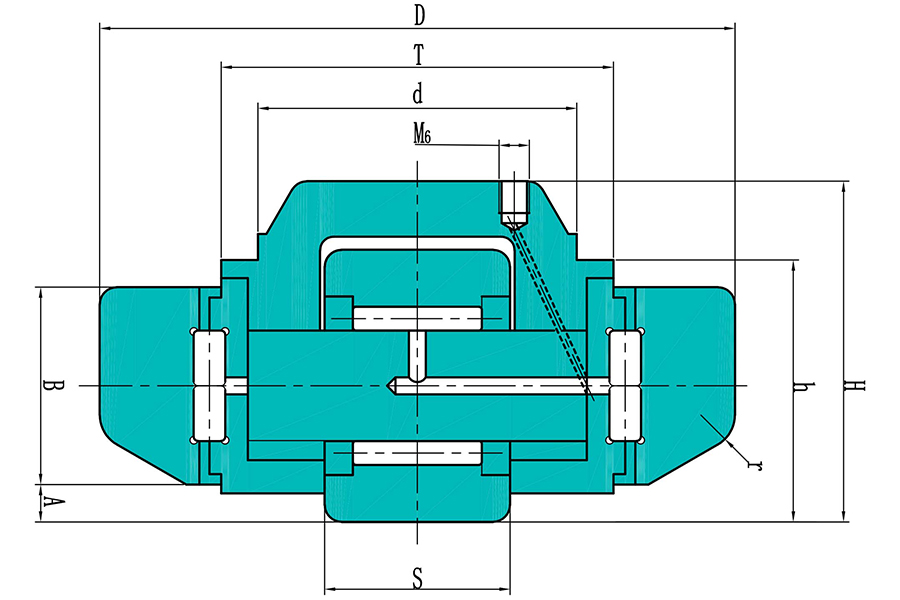

Наружный диаметр (D)

52.5mm-149mm

Габаритная ширина (B)

17mm-45mm

Диаметр болта (d)

30mm-60mm

Вес

0.46kg-6.85kg

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

| NO. | Product | Product Number | Диаметр болта (d) | Наружный диаметр (D) | Габаритная ширина (B) | Вес |

|---|---|---|---|---|---|---|

| 1 |

|

4.053 HT | 30 mm | 52.5 mm | 17 mm | 0.46 kg |

| 2 |

|

4.054 HT | 30 mm | 62.5 mm | 20 mm | 0.55 kg |

| 3 |

|

4.055 HT | 35 mm | 70.1 mm | 23 mm | 0.85 kg |

| 4 |

|

4.056 HT | 40 mm | 77.7 mm | 23 mm | 1.1 kg |

| 5 |

|

4.058 HT | 45 mm | 88.4 mm | 30 mm | 1.7 kg |

| 6 |

|

4.061 HT | 60 mm | 107.7 mm | 31 mm | 2.95 kg |

| 7 |

|

4.062 HT | 60 mm | 123 mm | 37 mm | 4.1 kg |

| 8 |

|

4.063 HT | 60 mm | 149 mm | 45 mm | 6.85 kg |

1. Особенности и преимущества высокотемпературного подшипника типа HT

Высокотемпературный подшипник типа HT решает несколько ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1) Несущая способность при комбинированной нагрузке

Высокотемпературный подшипник типа HT может нести радиальную и осевую нагрузку одновременно, и подходит для сложных условий, где две нагрузки действуют одновременно во время работы, особенно для приложений, которые должны нести крутящий момент и радиальную силу.

2) Экономия места и упрощение конструкции

Поскольку высокотемпературный подшипник типа HT воспринимает радиальные и осевые нагрузки одновременно, обычно нет необходимости использовать несколько подшипников в конструкции для разделения различных типов нагрузок, что позволяет экономить монтажное пространство.

В некоторых компактных конструкциях использование этого комбинированного подшипника может значительно упростить процесс сборки, уменьшить количество деталей, снизить затраты на производство и обслуживание.

3) Универсальность

Высокотемпературный подшипник типа HT может сочетать в себе характеристики различных подшипников для удовлетворения различных потребностей.

4) Широкая адаптивностьВысокотемпературный подшипник типа HT может быть разработан для адаптации к различным условиям эксплуатации по мере необходимости.

Высокотемпературный подшипник типа HT может быть разработан для адаптации к различным условиям эксплуатации по мере необходимости.

2. Улучшение характеристик и решения для высокотемпературных подшипников типа HT

1) Улучшение материалов

Выбор высокопроизводительных материалов: Использование материалов с более высокой твердостью, износостойкостью и коррозионной стойкостью может значительно повысить долговечность и стабильность подшипников.

2) Облегченная конструкция:

Снижение веса подшипников: Оптимизируя комбинацию материалов и конструкцию, сократите использование ненужных металлов, добейтесь облегчения веса и адаптируйтесь к сценариям применения с высокими требованиями к весу

3) Улучшение характеристик смазки

Высокоэффективные смазочные материалы: Используйте консистентную смазку или смазочное масло, которые лучше подходят для работы в условиях высоких температур и высокого давления, чтобы обеспечить стабильную работу смазочного масла при длительной работе, тем самым снижая трение в подшипниках и повышая их долговечность.

4) Улучшенная точность

Технология прецизионной обработки: Повышая точность изготовления и уменьшая погрешность между компонентами подшипника, обеспечивается более равномерный и стабильный контакт между игольчатым роликом и сепаратором. Это позволяет не только улучшить характеристики подшипника, но и продлить срок службы, а также снизить уровень шума и вибрации.

3. Основные области применения комбинированных игольчатых и упорных цилиндрических роликовых подшипников QIBR

1) Высокотемпературная печная система: Высокотемпературные подшипники типа HT широко используются в высокотемпературных печах, нагревательных печах, печах отжига и другом оборудовании в металлургической промышленности.

2) Газовая турбина: Высокотемпературный подшипник типа HT широко используется в энергетическом оборудовании, таком как газовые и паровые турбины.

3) Авиационные двигатели: высокотемпературные подшипники типа HT играют важную роль в авиационных двигателях.

4) Химическая промышленность

Высокотемпературный реактор: В химических реакторах и химических нагревательных печах процесс реакции часто приводит к чрезвычайно высоким температурам. Высокотемпературные подшипники типа HT могут использоваться для поддержки вращающейся части, обеспечивать стабильную работу в условиях высоких температур и гарантировать, что производственный процесс не будет прерван.

Теплообменное оборудование: В высокотемпературных теплообменниках высокотемпературные комбинированные роликовые подшипники могут нормально работать в условиях высокого давления и высокой температуры, обеспечивая эффективную работу теплообменного оборудования.