Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Внутренний диаметр

3mm-10mm

Наружный диаметр

15mm-40mm

Ширина

20mm-50mm

Динамическая радиальная нагрузка

10lbf-232lbf

Материал

NDI/POM Polyurethane

Номинальная статическая нагрузка, радиальная

3lbf-113lbf

Макс. частота вращения

19.2-36(X1000 rpm)

Бренд

QIBR/OEM/Neutral

| NO. | Product | Product Number | Материал шарика | Отверстие | Наружный диаметр (D) | Материал кольца | Тип уплотнения | Ширина |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

693 2rs | Chrome Steel | 3 mm | 15 mm | Chrome Steel | Sealed | 26 mm |

| 2 |

|

MR84 2rs | Chrome Steel | 4 mm | 15 mm | Chrome Steel | Sealed | 26 mm |

| 3 |

|

635 2rs | Chrome Steel | 5 mm | 30 mm | Chrome Steel | Sealed | 20 mm |

| 4 |

|

635 2rs | Chrome Steel | 5 mm | 30 mm | Chrome Steel | Sealed | 30 mm |

| 5 |

|

635 2rs | Chrome Steel | 5 mm | 30 mm | Chrome Steel | Sealed | 45 mm |

| 6 |

|

635 2rs | Chrome Steel | 5 mm | 30 mm | Chrome Steel | Sealed | 50 mm |

| 7 |

|

635 2rs | Chrome Steel | 5 mm | 32 mm | Chrome Steel | Sealed | 40 mm |

| 8 |

|

635 2rs | Chrome Steel | 5 mm | 35 mm | Chrome Steel | Sealed | 30 mm |

| 9 |

|

635 2rs | Chrome Steel | 5 mm | 35 mm | Chrome Steel | Sealed | 45 mm |

| 10 |

|

635 2rs | Chrome Steel | 5 mm | 35 mm | Chrome Steel | Sealed | 50 mm |

| 11 |

|

635 2rs | Chrome Steel | 5 mm | 40 mm | Chrome Steel | Sealed | 30 mm |

| 12 |

|

635 2rs | Chrome Steel | 5 mm | 40 mm | Chrome Steel | Sealed | 40 mm |

| 13 |

|

635 2rs | Chrome Steel | 5 mm | 40 mm | Chrome Steel | Sealed | 45 mm |

| 14 |

|

635 2rs | Chrome Steel | 5 mm | 40 mm | Chrome Steel | Sealed | 50 mm |

| 15 |

|

626 2rs | Chrome Steel | 6 mm | 30 mm | Chrome Steel | Sealed | 20 mm |

| 16 |

|

626 2rs | Chrome Steel | 6 mm | 30 mm | Chrome Steel | Sealed | 30 mm |

| 17 |

|

626 2rs | Chrome Steel | 6 mm | 30 mm | Chrome Steel | Sealed | 45 mm |

| 18 |

|

626 2rs | Chrome Steel | 6 mm | 30 mm | Chrome Steel | Sealed | 50 mm |

| 19 |

|

626 2rs | Chrome Steel | 6 mm | 32 mm | Chrome Steel | Sealed | 40 mm |

| 20 |

|

626 2rs | Chrome Steel | 6 mm | 35 mm | Chrome Steel | Sealed | 30 mm |

| 21 |

|

626 2rs | Chrome Steel | 6 mm | 35 mm | Chrome Steel | Sealed | 45 mm |

| 22 |

|

626 2rs | Chrome Steel | 6 mm | 35 mm | Chrome Steel | Sealed | 50 mm |

| 23 |

|

626 2rs | Chrome Steel | 6 mm | 40 mm | Chrome Steel | Sealed | 30 mm |

| 24 |

|

626 2rs | Chrome Steel | 6 mm | 40 mm | Chrome Steel | Sealed | 40 mm |

| 25 |

|

626 2rs | Chrome Steel | 6 mm | 40 mm | Chrome Steel | Sealed | 45 mm |

| 26 |

|

626 2rs | Chrome Steel | 6 mm | 40 mm | Chrome Steel | Sealed | 50 mm |

| 27 |

|

698 2rs | Chrome Steel | 8 mm | 30 mm | Chrome Steel | Sealed | 20 mm |

| 28 |

|

698 2rs | Chrome Steel | 8 mm | 30 mm | Chrome Steel | Sealed | 30 mm |

| 29 |

|

698 2rs | Chrome Steel | 8 mm | 30 mm | Chrome Steel | Sealed | 45 mm |

| 30 |

|

698 2rs | Chrome Steel | 8 mm | 30 mm | Chrome Steel | Sealed | 50 mm |

| 31 |

|

698 2rs | Chrome Steel | 8 mm | 32 mm | Chrome Steel | Sealed | 40 mm |

| 32 |

|

698 2rs | Chrome Steel | 8 mm | 35 mm | Chrome Steel | Sealed | 30 mm |

| 33 |

|

698 2rs | Chrome Steel | 8 mm | 35 mm | Chrome Steel | Sealed | 45 mm |

| 34 |

|

698 2rs | Chrome Steel | 8 mm | 35 mm | Chrome Steel | Sealed | 50 mm |

| 35 |

|

698 2rs | Chrome Steel | 8 mm | 40 mm | Chrome Steel | Sealed | 30 mm |

| 36 |

|

698 2rs | Chrome Steel | 8 mm | 40 mm | Chrome Steel | Sealed | 40 mm |

| 37 |

|

698 2rs | Chrome Steel | 8 mm | 40 mm | Chrome Steel | Sealed | 45 mm |

| 38 |

|

698 2rs | Chrome Steel | 8 mm | 40 mm | Chrome Steel | Sealed | 50 mm |

| 39 |

|

6800 2rs | Chrome Steel | 10 mm | 30 mm | Chrome Steel | Sealed | 20 mm |

| 40 |

|

6800 2rs | Chrome Steel | 10 mm | 30 mm | Chrome Steel | Sealed | 30 mm |

| 41 |

|

6800 2rs | Chrome Steel | 10 mm | 30 mm | Chrome Steel | Sealed | 45 mm |

| 42 |

|

6800 2rs | Chrome Steel | 10 mm | 30 mm | Chrome Steel | Sealed | 50 mm |

| 43 |

|

6800 2rs | Chrome Steel | 10 mm | 32 mm | Chrome Steel | Sealed | 40 mm |

| 44 |

|

6800 2rs | Chrome Steel | 10 mm | 35 mm | Chrome Steel | Sealed | 30 mm |

| 45 |

|

6800 2rs | Chrome Steel | 10 mm | 35 mm | Chrome Steel | Sealed | 45 mm |

| 46 |

|

6800 2rs | Chrome Steel | 10 mm | 35 mm | Chrome Steel | Sealed | 50 mm |

| 47 |

|

6800 2rs | Chrome Steel | 10 mm | 40 mm | Chrome Steel | Sealed | 30 mm |

| 48 |

|

6800 2rs | Chrome Steel | 10 mm | 40 mm | Chrome Steel | Sealed | 40 mm |

| 49 |

|

6800 2rs | Chrome Steel | 10 mm | 40 mm | Chrome Steel | Sealed | 45 mm |

| 50 |

|

6800 2rs | Chrome Steel | 10 mm | 40 mm | Chrome Steel | Sealed | 50 mm |

Особенности и преимущества аутсорсинга полиуретановых подшипников QIBR

Аутсорсинг полиуретановых подшипников QIBR решает несколько критических проблем в различных областях, в основном в следующих областях:

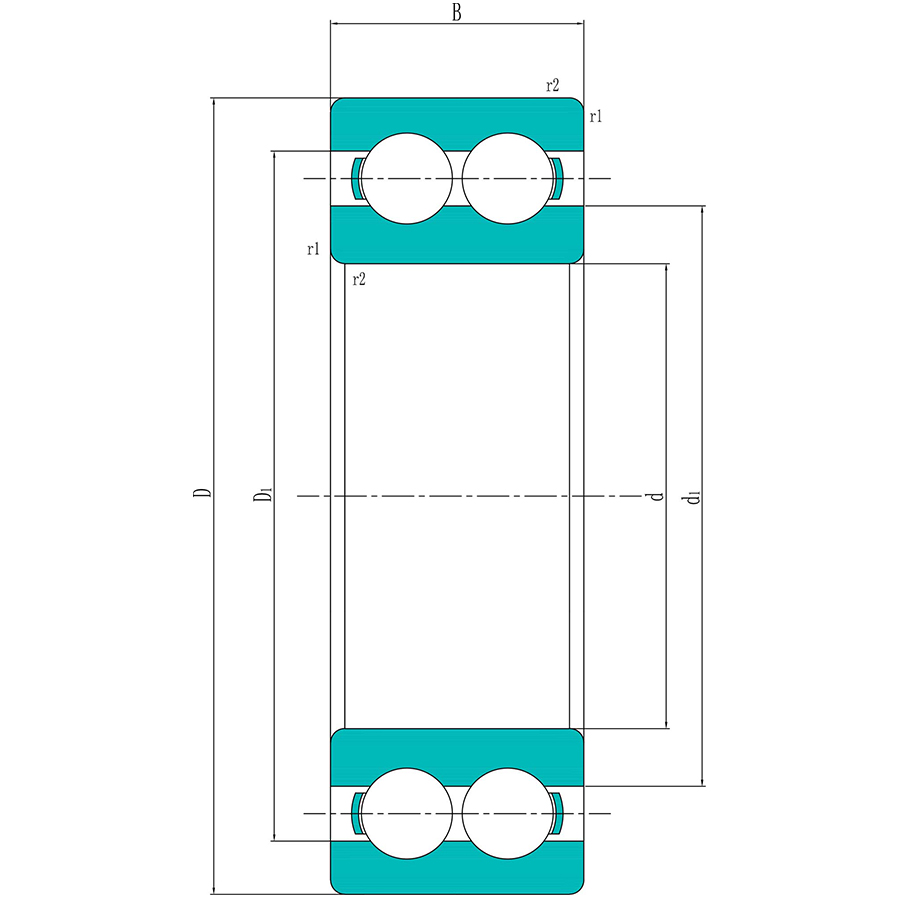

1. Двухрядная конструкция

Подшипники имеют двухрядную конструкцию, что обеспечивает лучшее распределение нагрузки и повышенную грузоподъемность.

2. Демпфирование вибраций и снижение уровня шума

Благодаря хорошей упругости и амортизирующим свойствам, эти подшипники эффективно поглощают вибрации и снижают уровень шума.

3. Масло- и химическая стойкость

Эти подшипники демонстрируют отличную стойкость к маслам, растворителям и различным химическим веществам.

4. Ударопрочность

Высокая эластичность полиуретана обеспечивает отличную ударопрочность, что делает подшипники пригодными для работы в условиях ударных нагрузок.

Улучшение характеристик и решения для полиуретановых подшипников Аутсорсинг QIBR

1. Повышение износостойкости

Добавление армирующих материалов (например, сажи, керамики, металлических порошков) позволяет повысить твердость и износостойкость полиуретана, обеспечивая стабильную работу при повышенных нагрузках и длительных условиях эксплуатации.

2. Повышение масло- и химической стойкости

В зависимости от условий применения выбор полиуретановых составов с повышенной стойкостью к химическим веществам и маслам может продлить срок службы подшипников в сложных условиях.

3. Оптимизация толщины полиуретанового слоя

Толщина полиуретанового слоя напрямую влияет на рабочие характеристики подшипников. Соответствующая толщина может повысить ударопрочность и износостойкость. Однако чрезмерная толщина может снизить жесткость подшипников, что негативно скажется на их эксплуатационных характеристиках. Хорошо спроектированный полиуретановый слой обеспечивает баланс между амортизацией, износостойкостью, несущей способностью и эксплуатационной стабильностью.

4. Оптимизация структуры внутренних и наружных дорожек качения

Оптимизация геометрии и размеров внутренних и наружных дорожек качения позволяет равномерно распределить усилие на полиуретановый слой, избегая локального чрезмерного износа.

Основные области применения полиуретановых подшипников QIBR на аутсорсинге

1. Автомобильная промышленность

Полиуретановые подшипники широко используются в автомобильном секторе, в частности, в системах подвески, привода и тормозных системах. Благодаря поглощению вибраций, снижению шума и долговечности, они используются в:

Оси автомобильных колес и системы подвески;

Компоненты двигателей и трансмиссий;

Колеса и тормозные системы.

2. Машиностроение

В машиностроении полиуретановые подшипники используются в различных высоконагруженных и износостойких механизмах. Их эластичность и прочность позволяют им работать в условиях больших нагрузок и сильных ударов.

3. Спортивное оборудование

Полиуретановые подшипники часто встречаются в спортивном оборудовании и инструментах, требующих износостойкости и ударопрочности, в том числе:

Скейтборды;

Сноуборды;

Велосипедные коньки и другие спортивные снаряды.

4. Аэрокосмическая промышленность

В аэрокосмической отрасли полиуретановые подшипники предпочитают за их превосходную высокотемпературную и износостойкую прочность. Они часто используются в компонентах самолетов, которые выдерживают высокоскоростные операции и экстремальные условия окружающей среды.

5. Робототехника и автоматизация

Полиуретановые подшипники также находят широкое применение в робототехнике и автоматическом оборудовании. Они обеспечивают высокоточные и высокоскоростные перемещения, снижая трение и шум, тем самым продлевая срок службы оборудования.