Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

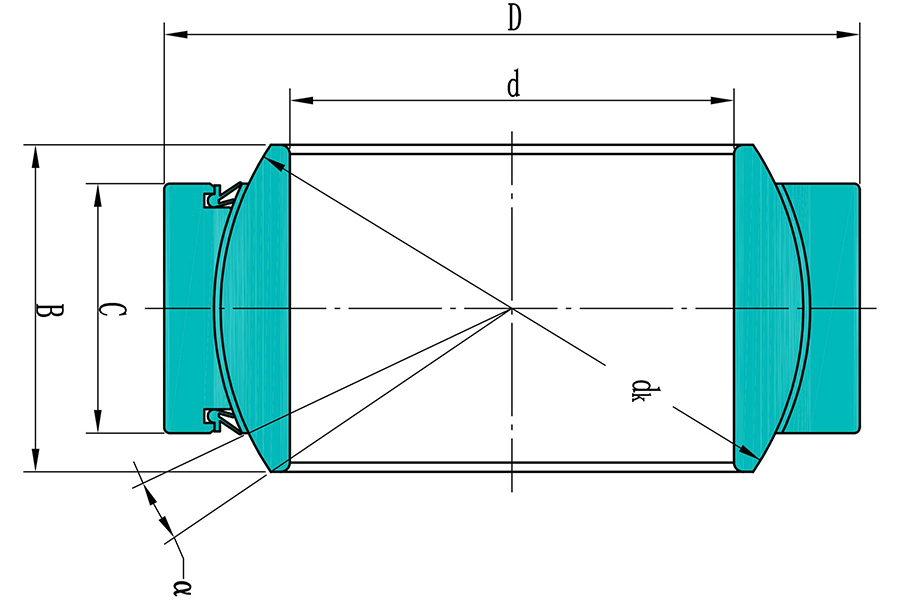

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

Material: GCr15

Внутренний диаметр кольца

6-280mm

Наружный диаметр кольца

16-430mm

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/OEM/ Industry standard package

Применения

Engineering Hydraulic Cylinder, Forging Machine, Construction Machinery, Automation Equipment, Automobile Shock Absorber, Water Conservancy Machinery

| NO. | Product | Product Number | Наружный диаметр (D) | Вал (d) | Вес | Ширина (B) |

|---|---|---|---|---|---|---|

| 1 |

|

GE6FW | 0.63"/16 mm | 0.236"/6 mm | 0.018 lbs | 0.354"/9 mm |

| 2 |

|

GE8FW | 0.748"/19 mm | 0.315"/8 mm | 0.031 lbs | 0.433"/11 mm |

| 3 |

|

GE12FW | 1.024"/26 mm | 0.472"/12 mm | 0.075 lbs | 0.591"/15 mm |

| 3 |

|

GE10FW | 0.866"/22 mm | 0.394"/10 mm | 0.044 lbs | 0.472"/12 mm |

| 5 |

|

GE15FW | 1.181"/30 mm | 0.591"/15 mm | 0.101 lbs | 0.630"/16 mm |

| 6 |

|

GE17FW | 1.378"/35 mm | 0.669"/17 mm | 0.172 lbs | 0.787"/20 mm |

| 7 |

|

GE20FW | 1.654"/42 mm | 0.787"/20 mm | 0.331 lbs | 0.984"/25 mm |

| 8 |

|

GE25FW | 1.850"/47 mm | 0.984"/25 mm | 0.419 lbs | 1.102"/28 mm |

| 9 |

|

GE30FW2RS | 2.165"/55 mm | 1.181"/30 mm | 0.639 lbs | 1.260"/32 mm |

| 10 |

|

GE35FW2RS | 2.441"/62 mm | 1.378"/35 mm | 0.86 lbs | 1.378"/35 mm |

| 11 |

|

GE40FW2RS | 2.677"/68 mm | 1.575"/40 mm | 1.147 lbs | 1.575"/40 mm |

| 12 |

|

GE45FW2RS | 2.953"/75 mm | 1.772"/45 mm | 1.499 lbs | 1.693"/43 mm |

| 13 |

|

GE50FW2RS | 3.543"/90 mm | 1.969"/50 mm | 3.087 lbs | 2.205"/56 mm |

| 14 |

|

GE60FW2RS | 4.134"/105 mm | 2.362"/60 mm | 4.41 lbs | 2.480"/63 mm |

| 15 |

|

GE70FW2RS | 4.724"/120 mm | 2.756"/70 mm | 6.395 lbs | 2.756"/70 mm |

| 16 |

|

GE80FW2RS | 5.118"/130 mm | 3.150"/80 mm | 7.718 lbs | 2.953"/75 mm |

| 17 |

|

GE90FW2RS | 5.906"/150 mm | 3.543"/90 mm | 11.91 lbs | 3.347"/85 mm |

| 18 |

|

GE100FW2RS | 6.299"/160 mm | 3.937"/100 mm | 13.01 lbs | 3.347"/85 mm |

| 19 |

|

GE110FW2RS | 7.087"/180 mm | 4.331"/110 mm | 21.39 lbs | 3.937"/100 mm |

| 20 |

|

GE120FW2RS | 8.268"/210 mm | 4.724"/120 mm | 33.08 lbs | 4.528"/115 mm |

| 21 |

|

GE140FW2RS | 9.055"/230 mm | 5.512"/140 mm | 40.79 lbs | 5.118"/130 mm |

| 22 |

|

GE160FW2RS | 10.236"/260 mm | 6.299"/160 mm | 55.13 lbs | 5.315"/135 mm |

| 23 |

|

GE180FW2RS | 11.417"/290 mm | 7.087"/180 mm | 78.28 lbs | 6.102"/155 mm |

| 24 |

|

GE200FW2RS | 12.598"/320 mm | 7.874"/200 mm | 99.23 lbs | 6.496"/165 mm |

| 25 |

|

GE220FW2RS | 13.386"/340 mm | 8.661"/220 mm | 112.46 lbs | 6.890"/175 mm |

| 26 |

|

GE240FW2RS | 14.567"/370 mm | 9.449"/240 mm | 141.12 lbs | 7.480"/190 mm |

| 27 |

|

GE260FW2RS | 15.748"/400 mm | 10.236"/260 mm | 178.61 lbs | 8.071"/205 mm |

| 28 |

|

GE280FW2RS | 16.929"/430 mm | 11.024"/280 mm | 207.27 lbs | 8.268"/210 mm |

Особенности и преимущества подшипников серии QIBR GE..FW,GE..FW-2RS

Подшипник шарнира QIBR серии GE..FW,GE..FW-2RS решает ряд важнейших проблем в различных областях, в основном в следующих областях:

1. Возможность разнонаправленного перемещения

Шарнирные подшипники QIBR серии GE..FW,GE..FW-2RS обычно предназначены для вращения или поворота в нескольких направлениях, что делает их идеальными для применений, требующих углового перемещения. Они обеспечивают большое относительное угловое перемещение между двумя соединенными деталями.

2. Высокая грузоподъемность

Шарнирные подшипники QIBR серии GE..FW,GE..FW-2RS способны выдерживать большие радиальные и осевые нагрузки. Его сферическая конструкция эффективно рассеивает и воспринимает большие усилия, благодаря чему он отлично работает в высокопрочных рабочих средах.

3. Сильная износостойкость

В шарнирных подшипниках QIBR серии GE...FW,GE...FW-2RS используются износостойкие материалы для эффективного снижения коэффициента трения и повышения износостойкости подшипника. Некоторые шарнирные подшипники из композитных материалов даже не требуют смазки, что делает их пригодными для работы в тяжелых условиях.

4. Сильная адаптивность

Подшипники QIBR серии GE..FW,GE..FW-2RS могут адаптироваться к различным условиям работы и окружающей среде, включая перепады температуры, влажность, загрязнения и пыль.

Улучшение характеристик и решения для подшипников сочленения QIBR серии GE..FW,GE..FW-2RS

1. Оптимизация смазочных материалов

Выбор подходящих смазочных материалов (масла или консистентной смазки) и соответствующих составов присадок для снижения трения и повышения износостойкости.

2. Оптимизация дорожек качения

Оптимизация геометрии внутренних и внешних дорожек качения, например, повышение точности дорожек и улучшение качества поверхности, для снижения трения, минимизации потерь энергии и повышения эффективности подшипника.

3. Прецизионное производство и контроль допусков

Благодаря использованию прецизионной обработки и строгому контролю допусков внутренняя структура подшипника шарнира может быть сделана более гладкой и точной. Точное изготовление помогает уменьшить ненужное трение, повысить эффективность работы и смягчить последствия несбалансированных нагрузок.

4. Увеличенная площадь распределения нагрузки

Оптимизация конструкции контактной поверхности шарнирного подшипника с целью увеличения площади распределения нагрузки позволяет снизить локальную концентрацию напряжений, повысить грузоподъемность и продлить срок службы.

Main application areas of QIBR joint bearing GE..FW,GE..FW-2RS series

1. Автомобильная промышленность

В автомобильных системах подвески шарнирные подшипники обычно используются для соединения подвижных частей между колесами и кузовом, адаптируясь к различным динамическим нагрузкам и движениям.

Системы рулевого управления: Используются в шаровых шарнирах рулевого управления и кронштейнах шаровых шарниров, обеспечивая гибкую регулировку направления движения.

Регулировка сидений: Шарнирный подшипник используется в механизме регулировки автомобильных сидений, обеспечивая плавное и гибкое перемещение сиденья.

2. Аэрокосмическая промышленность

Шасси самолетов: Шарнирные подшипники являются ключевыми компонентами шасси самолета, помогая ему выдерживать большие нагрузки и обеспечивая гибкость при взлете и посадке.

3. Сельскохозяйственная техника

Сельскохозяйственное почвообрабатывающее оборудование: Шарнирные подшипники используются в тракторах, зерноуборочных комбайнах, опрыскивателях и другой сельскохозяйственной технике, выдерживая высокие нагрузки, высокие температуры и агрессивные среды, обеспечивая стабильность оборудования.

Системы трансмиссии: Используются в сельскохозяйственной технике для передачи мощности в узлах трансмиссии.

4. Строительная техника

Краны и экскаваторы: Подшипники шарниров широко используются в подвижных частях кранов, экскаваторов и аналогичного оборудования для обеспечения гибкого перемещения шарниров и вращающихся частей, выдерживая сложные рабочие нагрузки.

Погрузчики и подъемники: Шарнирные подшипники используются для соединения или поддержки вращающихся, подъемных и других подвижных компонентов этих машин, повышая эффективность работы.