Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

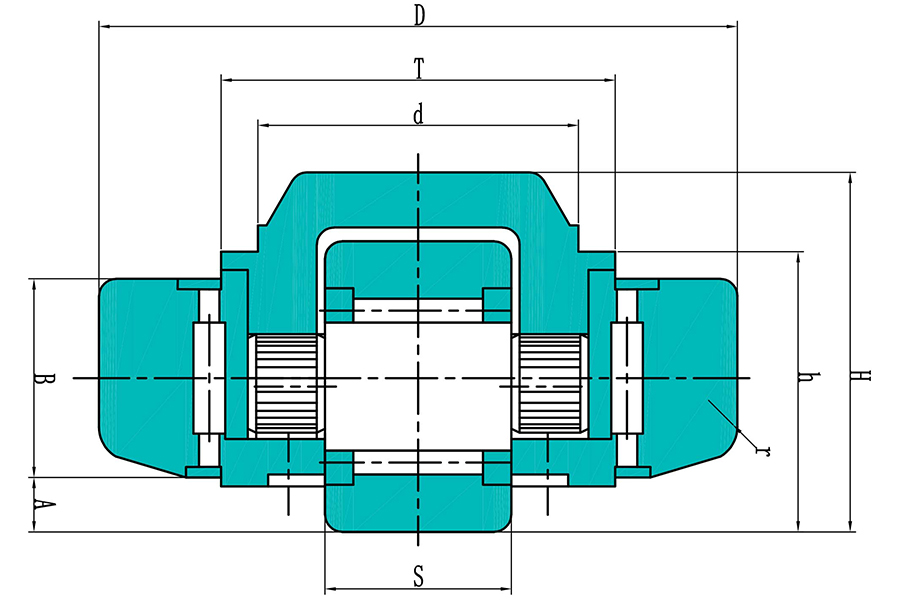

Наружный диаметр (D)

62.5mm-149.4mm

Габаритная ширина (B)

20mm-45mm

Диаметр болта (d)

30mm-60mm

Вес

0.53kg-6.3kg

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

| NO. | Product | Product Number | Диаметр болта (d) | Наружный диаметр (D) | Габаритная ширина (B) | Вес |

|---|---|---|---|---|---|---|

| 1 |

|

4.454 | 30 mm | 62.5 mm | 20 mm | 0.53 kg |

| 2 |

|

4.455 | 35 mm | 70.1 mm | 23 mm | 0.8 kg |

| 3 |

|

4.456 | 40 mm | 77.7 mm | 23 mm | 1 kg |

| 4 |

|

4.457 | 40 mm | 77.7 mm | 23 mm | 0.87 kg |

| 5 |

|

4.458 | 45 mm | 88.4 mm | 30 mm | 1.62 kg |

| 6 |

|

4.459 | 50 mm | 101.6 mm | 26 mm | 1.74 kg |

| 7 |

|

4.460 | 55 mm | 108.5 mm | 31 mm | 2.27 kg |

| 8 |

|

4.461 | 60 mm | 107.7 mm | 31 mm | 2.82 kg |

| 9 |

|

4.462 | 60 mm | 123 mm | 37 mm | 3.6 kg |

| 10 |

|

4.463 | 60 mm | 149.4 mm | 45 mm | 6.3 kg |

1. Особенности и преимущества эксцентрикового регулируемого упорного подшипника QIBR

Эксцентриковый регулируемый упорный подшипник решает множество важнейших задач в различных областях, прежде всего, в следующих аспектах:

1) Композитная грузоподъемность

Упорный подшипник эксцентриковый регулируемый может одновременно выдерживать радиальные и осевые нагрузки, что делает его подходящим для сложных условий, где оба типа нагрузок действуют совместно, особенно в приложениях, требующих крутящего момента и радиальной силы.

2) Экономия места и упрощение конструкции

Поскольку упорный регулируемый эксцентрик воспринимает как радиальные, так и осевые нагрузки, часто нет необходимости использовать несколько подшипников для передачи различных типов нагрузок. Это позволяет сэкономить место для установки. В компактных конструкциях использование таких комбинированных подшипников позволяет значительно упростить процесс сборки, уменьшить количество компонентов и снизить затраты на производство и обслуживание.

3) Приспособленность к асимметричным нагрузкам

Упорный регулируемый эксцентриковый подшипник может эффективно справляться с нагрузками, вызванными асимметричными нагрузками во время работы оборудования.

4) Широкие возможности адаптации

Упорный регулируемый эксцентриковый подшипник может быть разработан для различных условий эксплуатации по мере необходимости.

2. Улучшение характеристик и решения для эксцентрикового регулируемого упорного подшипника

1) Улучшение материалов

Выбор высокопроизводительного материала: Использование материалов с более высокой твердостью, износостойкостью и коррозионной стойкостью может значительно повысить долговечность и стабильность подшипника.

2) Облегченная конструкция

Снижение веса подшипника: Оптимизация сочетания материалов и конструкции позволяет свести к минимуму использование ненужных металлов, что позволяет получить легкие решения, подходящие для чувствительных к весу приложений.

3) Улучшение смазочных характеристик

Эффективные смазочные материалы: Использование смазочных материалов или масел, лучше подходящих для работы в условиях высоких температур и высокого давления, обеспечивает стабильные характеристики при длительной эксплуатации, снижая трение и повышая долговечность.

4) Повышение точности

Технология прецизионной обработки: Повышение точности изготовления сводит к минимуму погрешности между компонентами подшипника, обеспечивая более равномерный и стабильный контакт между роликами и сепараторами. Это не только улучшает рабочие характеристики, но и продлевает срок службы, снижая уровень шума и вибрации.

3. Основные области применения упорного подшипника эксцентрикового регулируемого

1) Ветроэнергетическое оборудование

Упорный подшипник эксцентриковый регулируемый используется в основных подшипниках ветровых турбин, подшипниках редукторов и других компонентах. Эти подшипники должны выдерживать огромные нагрузки и сохранять оптимальную производительность в суровых условиях окружающей среды.

2) Промышленное оборудование

В промышленном оборудовании эксцентрики упорных подшипников широко используются в различных устройствах, таких как гидравлические системы, станки с ЧПУ, автоматизированные производственные линии и конвейерные ленты. Они обеспечивают повышенную износостойкость, снижают затраты на обслуживание и повышают надежность механических систем.

3) Нефтегазовая промышленность

Упорный подшипник с эксцентриковой регулировкой играет важную роль в нефтяном бурении, морских платформах и оборудовании для добычи природного газа. Эти подшипники работают в условиях экстремальных температур, давления и коррозионной среды.

4) Сельскохозяйственная техника

В сельскохозяйственной технике регулируемые эксцентрики упорных подшипников применяются в тракторах, комбайнах, сеялках и другом оборудовании. Его износостойкость и коррозионная стойкость позволяют машинам эффективно работать в тяжелых условиях.