Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN/VDEh,DIN/VDEh

Наружный диаметр

30mm-45mm

Ширина

20mm-50mm

Динамическая радиальная нагрузка

58lbf-232lbf

Материал

NDI/POM Polyurethane

Базовая статическая нагрузка, радиальная

22lbf-113lbf

Макс. частота вращения

19.2-24(X1000 rpm)

Бренд

QIBR/OEM/Neutral

ODM/OEM

Support

| NO. | Product | Product Number | Наружный диаметр (D) | Материал кольца | Длина винта | Тип уплотнения | Материал щита | Ширина |

|---|---|---|---|---|---|---|---|---|

| 1 |

|

626 2rs | 32 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 2 |

|

6800 2rs | 32 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 3 |

|

698 2rs | 32 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 4 |

|

626 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 5 |

|

626 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 6 |

|

626 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 7 |

|

626 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 8 |

|

626 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 10 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 11 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 12 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 13 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 14 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 15 |

|

6800 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 16 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 17 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 18 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 19 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 20 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 21 |

|

698 2rs | 35 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 22 |

|

626 2rs | 45 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 23 |

|

6800 2rs | 45 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 24 |

|

698 2rs | 45 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 25 |

|

626 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 26 |

|

626 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 27 |

|

626 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 28 |

|

626 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 29 |

|

626 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 30 |

|

6800 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 31 |

|

6800 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 31 |

|

6800 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 32 |

|

6800 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 33 |

|

698 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 34 |

|

698 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 35 |

|

698 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 35 |

|

698 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 36 |

|

698 2rs | 30 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 37 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 38 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 39 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 40 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 41 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 42 |

|

626 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 43 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 44 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 45 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 46 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 47 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 48 |

|

6800 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

| 49 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 20 mm |

| 50 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 30 mm |

| 51 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 35 mm |

| 52 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 40 mm |

| 53 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 45 mm |

| 54 |

|

698 2rs | 40 mm | Chrome Steel | 9 mm | Sealed | NBR | 50 mm |

Особенности и преимущества аутсорсинга QIBR с полиуретановым покрытием с винтом

Аутсорсинг QIBR с полиуретановым покрытием с винтом решает несколько критических проблем в различных областях, в основном в следующих областях:

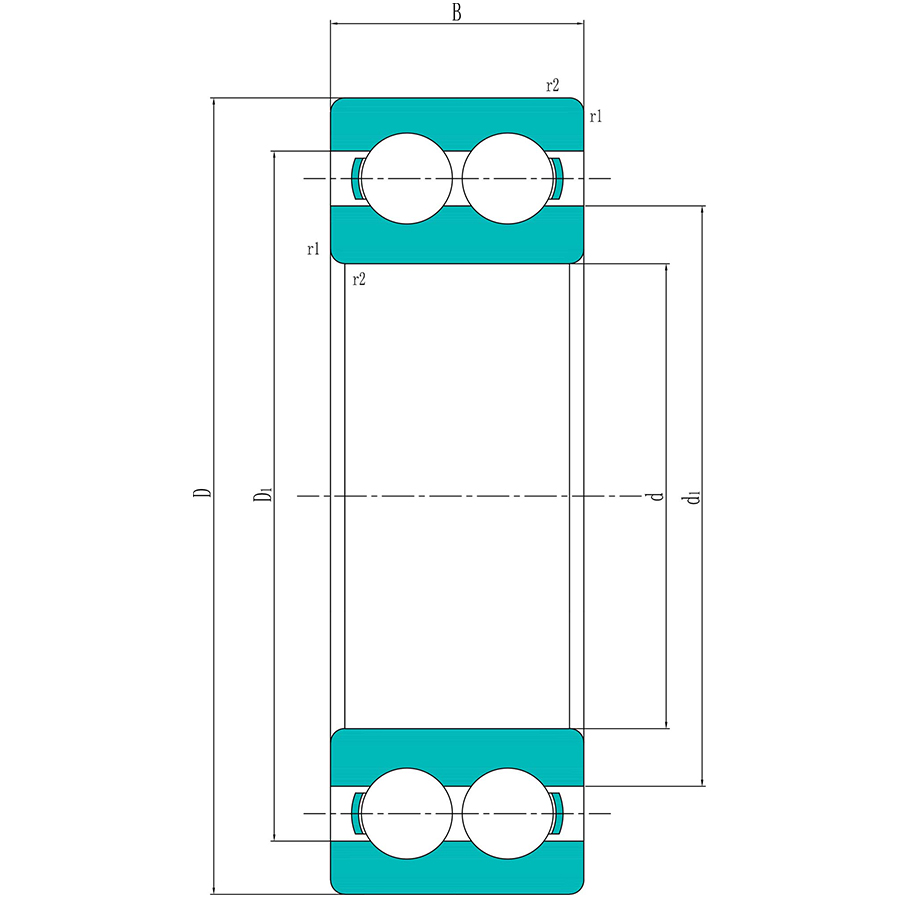

1. Двухрядная конструкция

Подшипники имеют двухрядную конструкцию, что обеспечивает лучшее распределение нагрузки и повышенную грузоподъемность.

2. Демпфирование вибраций и снижение уровня шума

Благодаря хорошей упругости и амортизирующим свойствам, эти подшипники эффективно поглощают вибрации и снижают уровень шума.

3. Масло- и химическая стойкость

Эти подшипники демонстрируют отличную стойкость к маслам, растворителям и различным химическим веществам.

4. Ударопрочность

Высокая эластичность полиуретана обеспечивает отличную ударопрочность, что делает подшипники пригодными для работы в условиях ударных нагрузок

Улучшение характеристик и решения для аутсорсинга QIBR подшипников с полиуретановым покрытием с винтом

1. Повышение износостойкости

Добавление армирующих материалов (например, сажи, керамики, металлических порошков) позволяет повысить твердость и износостойкость полиуретана, обеспечивая стабильную работу при повышенных нагрузках и длительных условиях эксплуатации.

2. Повышение масло- и химической стойкости

В зависимости от условий применения выбор полиуретановых составов с повышенной стойкостью к химическим веществам и маслам может продлить срок службы подшипников в сложных условиях.

3. Оптимизация толщины полиуретанового слоя

Толщина полиуретанового слоя напрямую влияет на рабочие характеристики подшипников. Соответствующая толщина может повысить ударопрочность и износостойкость. Однако чрезмерная толщина может снизить жесткость подшипников, что негативно скажется на их эксплуатационных характеристиках. Хорошо спроектированный полиуретановый слой обеспечивает баланс между амортизацией, износостойкостью, несущей способностью и эксплуатационной стабильностью.

4. Оптимизация структуры внутренних и наружных дорожек качения

Оптимизация геометрии и размеров внутренних и наружных дорожек качения позволяет равномерно распределить усилие на полиуретановый слой, избегая локального чрезмерного износа.