Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh

Материал

GCr15

Внутренний диаметр кольца

25-200mm

Наружный диаметр кольца

47-310mm

Вес

0.13-23kg

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

Применения

Engineering Hydraulic Cylinder, Forging Machine, Construction Machinery, Automation Equipment, Automobile Shock Absorber, Water Conservancy Machinery

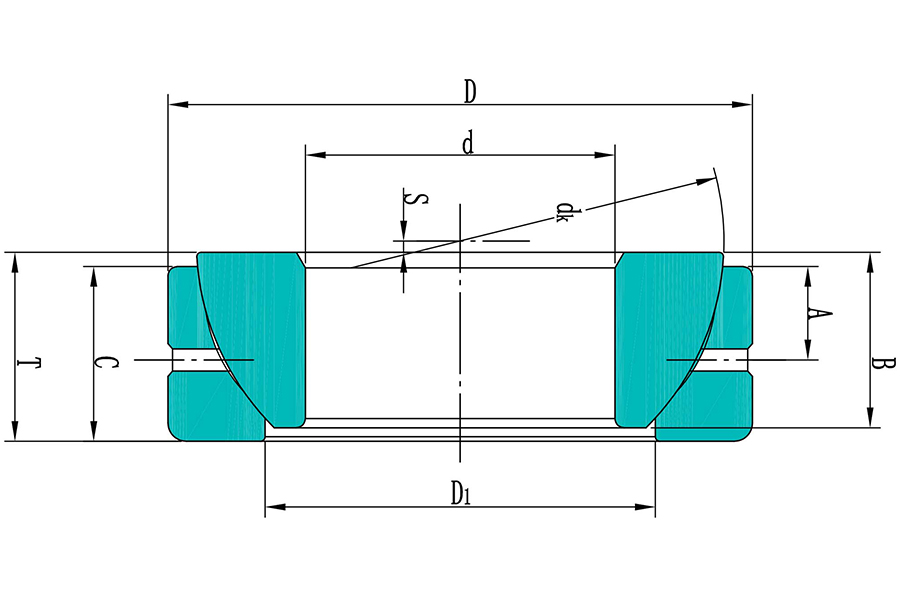

| NO. | Product | Product Number | Наружный диаметр (D) | Вал (d) | Вес | Ширина (B) |

|---|---|---|---|---|---|---|

| 1 |

|

GE25SX | 1.85"/47 mm | 0.984"/25 mm | 0.287 lbs | 0.551"/14 mm |

| 2 |

|

GE28SX | 2.047"/52 mm | 1.102"/28 mm | 0.375 lbs | 0.591"/15 mm |

| 3 |

|

GE30SX | 2.165"/55 mm | 1.181"/30 mm | 0.463 lbs | 0.630"/16 mm |

| 4 |

|

GE35SX | 2.441"/62 mm | 1.378"/35 mm | 0.595 lbs | 0.669"/17 mm |

| 5 |

|

GE40SX | 2.677"/68 mm | 1.575"/40 mm | 0.706 lbs | 0.709"/18 mm |

| 6 |

|

GE45SX | 2.953"/75 mm | 1.772"/45 mm | 0.904 lbs | 0.748"/19 mm |

| 7 |

|

GE50SX | 3.150"/80 mm | 1.969"/50 mm | 0.992 lbs | 0.748"/19 mm |

| 8 |

|

GE55SX | 3.543"/90 mm | 2.165"/55 mm | 1.477 lbs | 0.866"/22 mm |

| 9 |

|

GE60SX | 3.740"/95 mm | 2.362"/60 mm | 1.588 lbs | 0.866"/22 mm |

| 10 |

|

GE65SX | 3.937"/100 mm | 2.559"/65 mm | 1.676 lbs | 0.866"/22 mm |

| 11 |

|

GE70SX | 4.331"/110 mm | 2.756"/70 mm | 2.205 lbs | 0.945"/24 mm |

| 12 |

|

GE80SX | 4.921"/125 mm | 3.150"/80 mm | 3.308 lbs | 1.063"/27 mm |

| 13 |

|

GE90SX | 5.512"/140 mm | 3.543"/90 mm | 4.631 lbs | 1.181"/30 mm |

| 14 |

|

GE100SX | 5.906"/150 mm | 3.937"/100 mm | 5.072 lbs | 1.181"/30 mm |

| 15 |

|

GE110SX | 6.693"/170 mm | 4.331"/110 mm | 7.938 lbs | 1.417"/36 mm |

| 16 |

|

GE120SX | 7.087"/180 mm | 4.724"/120 mm | 8.600 lbs | 1.417"/36 mm |

| 17 |

|

GE130SX | 7.874"/200 mm | 5.118"/130 mm | 13.010 lbs | 1.654"/42 mm |

| 18 |

|

GE140SX | 8.268"/210 mm | 5.512"/140 mm | 13.892 lbs | 1.654"/42 mm |

| 19 |

|

GE150SX | 8.858"/225 mm | 5.906"/150 mm | 16.979 lbs | 1.772"/45 mm |

| 20 |

|

GE160SX | 9.449"/240 mm | 6.299"/160 mm | 20.727 lbs | 1.890"/48 mm |

| 21 |

|

GE170SX | 10.236"/260 mm | 6.693"/170 mm | 26.460 lbs | 2.126"/54 mm |

| 22 |

|

GE180SX | 11.024"/280 mm | 7.087"/180 mm | 37.485 lbs | 2.402"/61 mm |

| 23 |

|

GE190SX | 11.417"/290 mm | 7.480"/190 mm | 39.690 lbs | 2.402"/61 mm |

| 24 |

|

GE200SX | 12.205"/310 mm | 7.874"/200 mm | 49.613 lbs | 2.598"/66 mm |

Особенности и преимущества сферического подшипника QIBR серии GE...SX

Сферический подшипник QIBR серии GE...SX решает множество ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1. Возможность многонаправленного движения

Сферические подшипники QIBR серии GE..SX обычно предназначены для вращения или поворота в нескольких направлениях, поэтому они очень подходят для случаев, требующих углового перемещения. Они могут обеспечить большое относительное угловое перемещение между двумя взаимосвязанными деталями.

2. Высокая несущая способность

Сферический подшипник QIBR серии GE...SX может выдерживать большие радиальные и осевые нагрузки. Его сферическая конструкция позволяет эффективно рассеивать и переносить большие усилия, поэтому он хорошо работает в условиях высокой интенсивности.

3. Сильная износостойкость

В сферических подшипниках QIBR серии GE...SX используются износостойкие материалы для эффективного снижения коэффициента трения и повышения износостойкости подшипника. Некоторые композитные сферические подшипники даже не требуют смазки и подходят для работы в тяжелых условиях.

4. Сильная адаптивность

Сферические подшипники QIBR серии GE...SX могут адаптироваться к различным условиям работы и окружающей среде, включая изменения температуры, влажность, загрязняющие вещества и пыль.

Улучшение характеристик и решения сферического подшипника QIBR серии GE...SX

1. Оптимизация смазочного материала: Выберите подходящее смазочное масло или консистентную смазку и сделайте соответствующие добавки и смеси для снижения трения и повышения износостойкости.

2. Оптимизация дорожек качения: Оптимизация геометрии дорожки качения внутреннего и наружного колец, например, повышение точности дорожки качения, улучшение качества поверхности, снижение трения, уменьшение потерь энергии и, таким образом, повышение эффективности работы подшипника.

3. Точность изготовления и контроль допусков: Благодаря прецизионной обработке и строгому контролю допусков, внутренняя структура сферического подшипника становится более гладкой и точной. Точное изготовление может эффективно уменьшить ненужное трение, повысить эффективность работы и уменьшить влияние несбалансированных нагрузок.

4. Увеличение поверхности распределения нагрузки: Оптимизация конструкции контактной поверхности сферического подшипника и увеличение площади распределения нагрузки позволяет снизить локальную концентрацию напряжений, повысить грузоподъемность и продлить срок службы.

Основные области применения совместного подшипника QIBR серии GE...SX

1. Автомобильная промышленность

Система подвески: В системе подвески автомобилей шарнирные подшипники часто используются для соединения подвижных частей между колесами и кузовом, и могут адаптироваться к различным динамическим нагрузкам и движениям.

Система рулевого управления: Используются в таких компонентах, как шаровые головки рулевого управления и кронштейны шаровых головок, для обеспечения гибкой регулировки направления.

Регулировка сиденья: Шарнирные подшипники используются в механизме регулировки автомобильных сидений, позволяя сиденьям двигаться плавно и гибко.

2. Шпиндель станка

Шпиндели станков обычно должны выдерживать высокоточные, высокоскоростные и высоконагруженные условия работы. Шарнирные подшипники могут эффективно выдерживать комбинированные нагрузки (т.е. одновременные радиальные и осевые нагрузки), обеспечивая стабильность и точность шпинделя.

3. Сельскохозяйственная техника

Сельскохозяйственная техника: В сельскохозяйственной технике, такой как тракторы, зерноуборочные комбайны, опрыскиватели и т.д., используются шарнирные подшипники, выдерживающие высокие нагрузки, устойчивые к высоким температурам и коррозии для обеспечения стабильности работы оборудования.

Система трансмиссии: Используется для компонентов трансмиссии в сельскохозяйственном оборудовании для переноса и передачи энергии.

4. Строительная техника

Кран, экскаватор: Сферические подшипники широко используются в подвижных частях кранов, экскаваторов и другого оборудования, чтобы помочь шарнирам и вращающимся частям двигаться гибко и выдерживать сложные рабочие нагрузки.

Вилочные погрузчики, краны: В этих машинах сферические подшипники используются для соединения или поддержки вращающихся, подъемных и других движущихся частей для повышения эффективности работы.