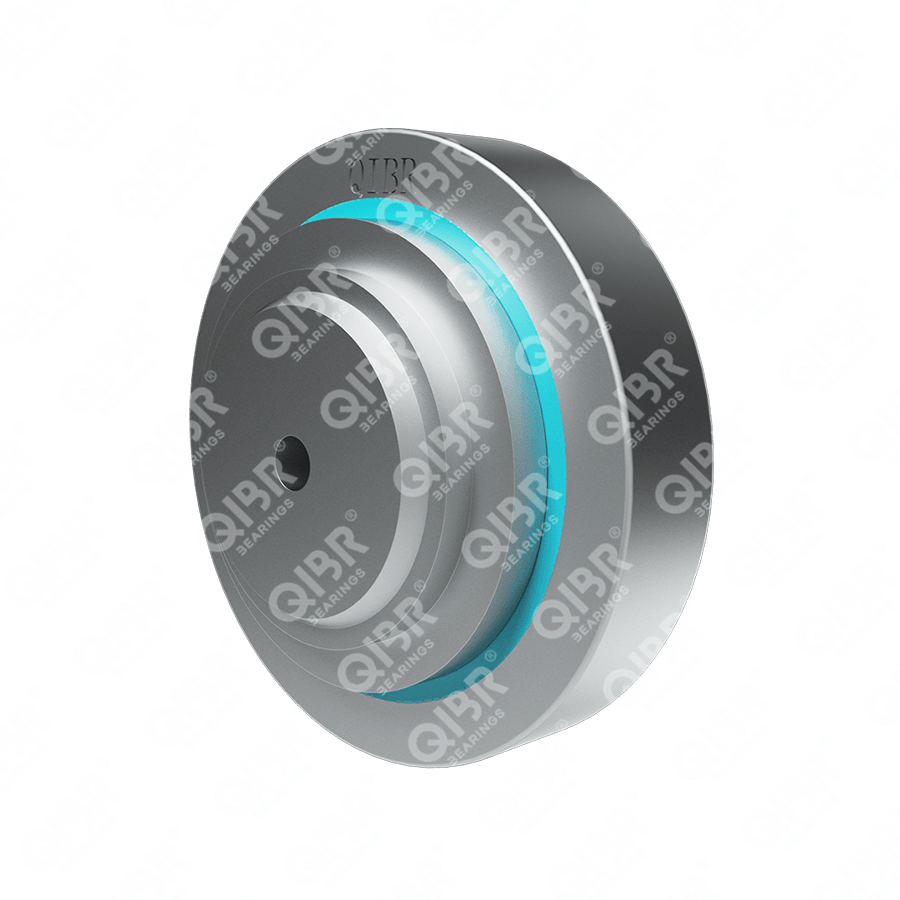

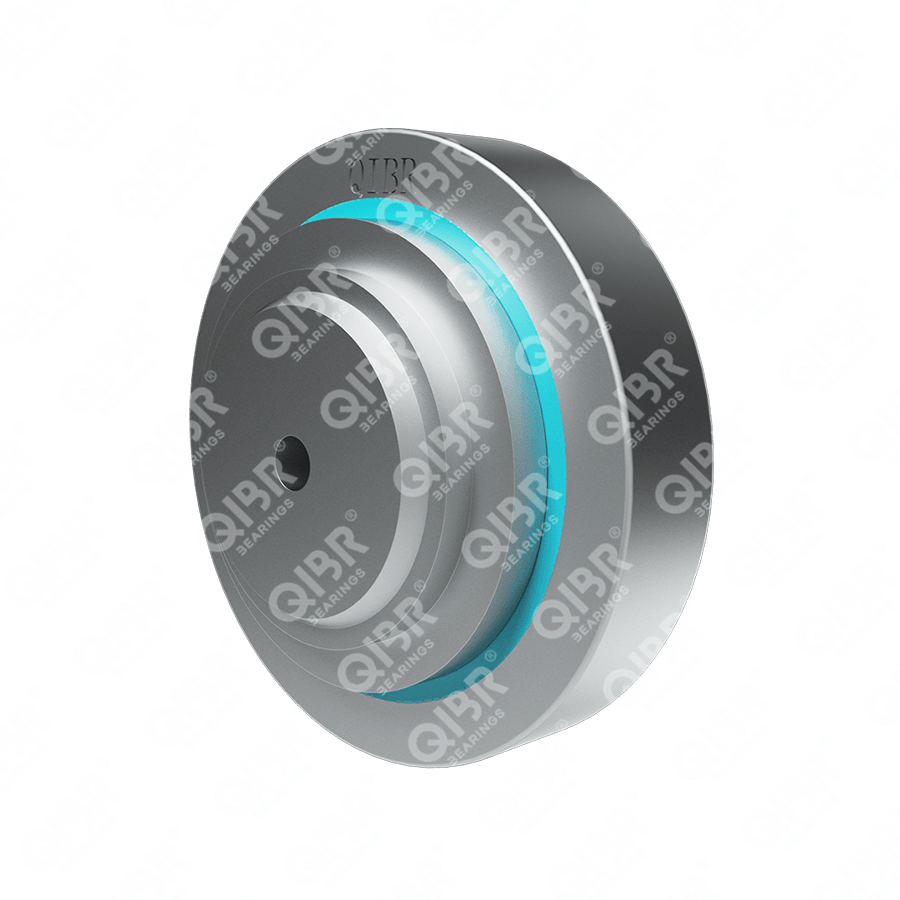

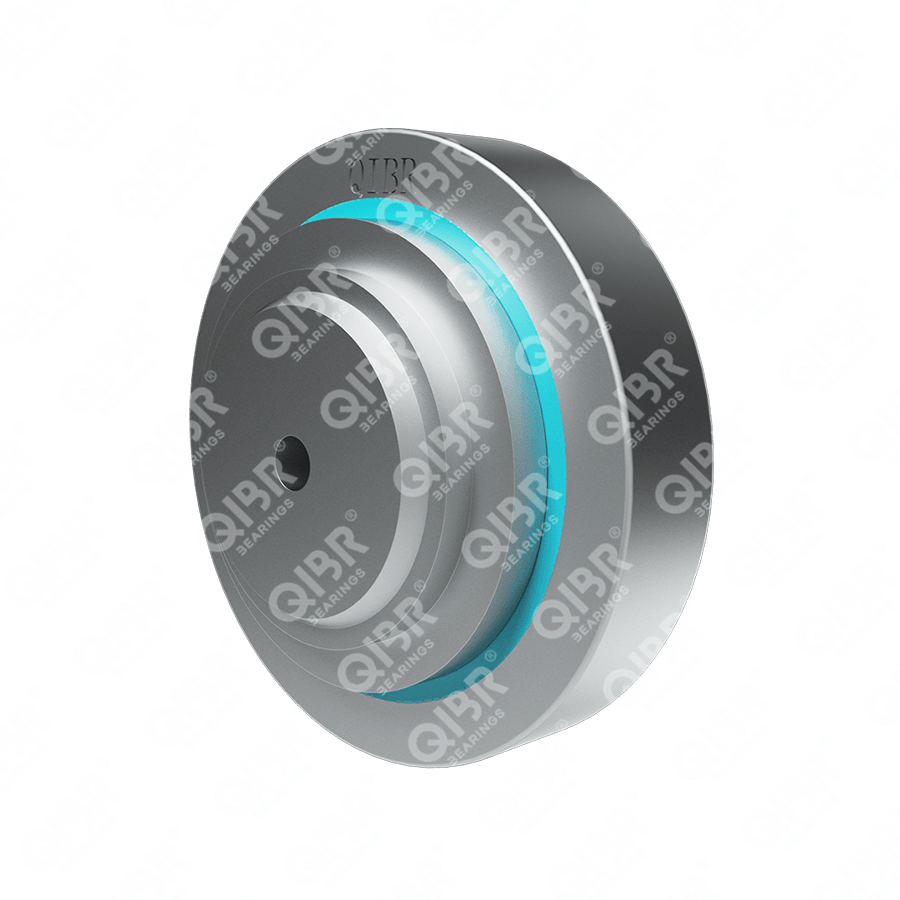

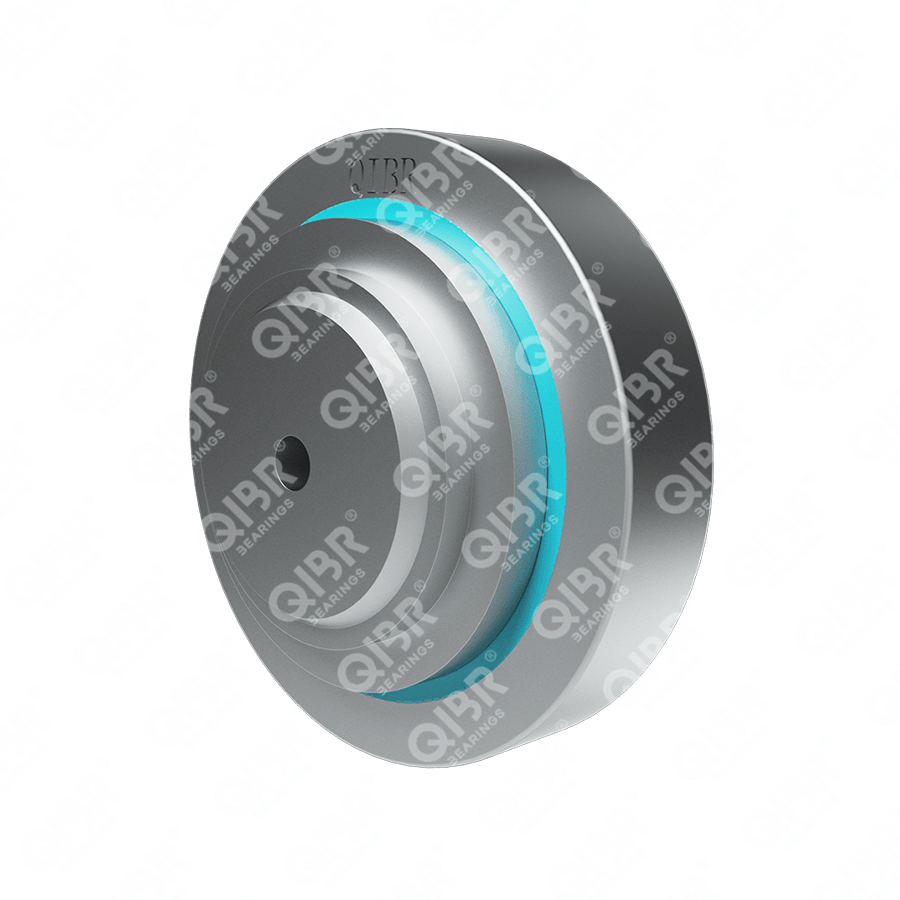

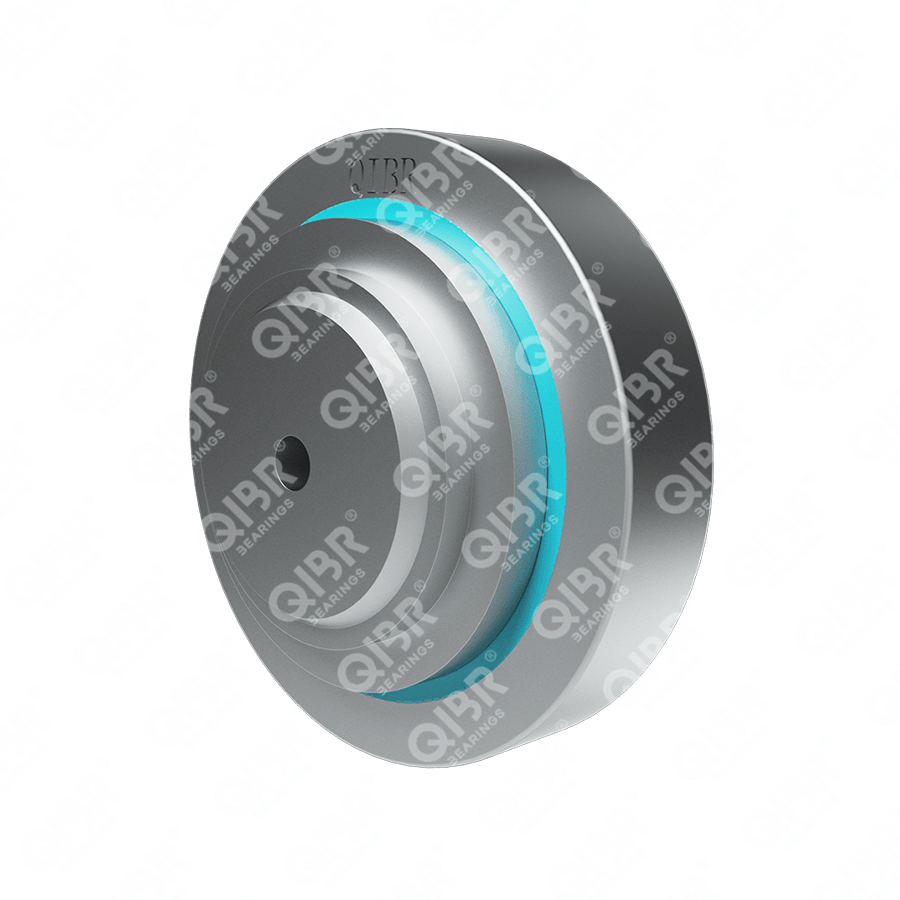

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

Стандарт

GB,ASTM/AISI,ГОСТ,BS,JIS,NF,DIN / VDEh,DIN / VDEh

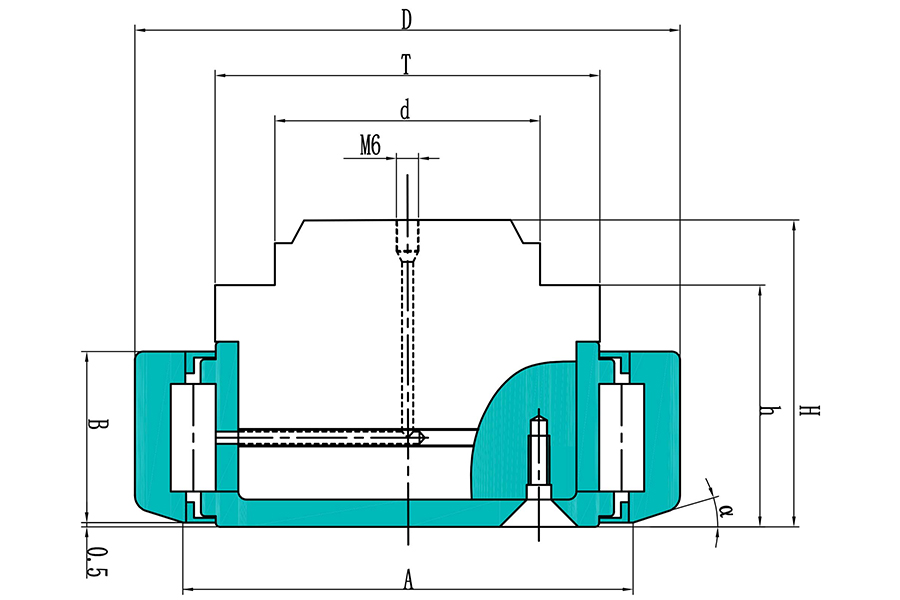

Наружный диаметр (D)

64.8mm-153.8mm

Габаритная ширина (B)

20mm-45mm

Диаметр болта (d)

30mm-60mm

Вес

0.55kg-6.7kg

Бренд

QIBR/OEM/Neutral

Упаковка

QIBR/Standard Industrial Package/OEM

| NO. | Product | Product Number | Диаметр болта (d) | Наружный диаметр (D) | Габаритная ширина (B) | Вес |

|---|---|---|---|---|---|---|

| 1 |

|

PR 2.054 | 30 mm | 64.8 mm | 20 mm | 0.55 kg |

| 2 |

|

PR 2.055 | 35 mm | 73.8 mm | 23 mm | 0.8 kg |

| 3 |

|

PR 2.056 | 40 mm | 81.8 mm | 23 mm | 1.05 kg |

| 4 |

|

PR 2.058 | 45 mm | 92.8 mm | 30 mm | 1.7 kg |

| 5 |

|

PR 2.061 | 60 mm | 111.8 mm | 31 mm | 2.9 kg |

| 6 |

|

PR 2.062 | 60 mm | 127.8 mm | 37 mm | 4 kg |

| 7 |

|

PR 2.063 | 60 mm | 153.8 mm | 45 mm | 6.7 kg |

1. Особенности и преимущества прецизионного радиального подшипника типа PR

Прецизионный радиальный подшипник типа PR решает несколько ключевых проблем в различных областях, которые в основном отражены в следующих аспектах:

1) Экономия места и упрощение конструкции

Поскольку конструкция прецизионного радиального подшипника типа PR состоит только из тел качения в радиальном направлении и не имеет тел качения в осевом направлении, конструкция упрощается, что позволяет экономить монтажное пространство.

В некоторых компактных конструкциях использование этого комбинированного подшипника может значительно упростить процесс сборки, уменьшить количество деталей и снизить затраты на производство и обслуживание.

2) Универсальность

Прецизионный радиальный подшипник типа PR может сочетать в себе характеристики различного оборудования для удовлетворения различных потребностей.

3) Широкие возможности адаптации

Прецизионный радиальный подшипник типа PR может быть разработан таким образом, чтобы адаптироваться к различным условиям эксплуатации.

2. Улучшение характеристик и решения для прецизионных радиальных подшипников типа PR

1) Улучшенные материалы

Выбор высокоэффективных материалов: Использование материалов с более высокой твердостью, износостойкостью и коррозионной стойкостью может значительно повысить долговечность и стабильность подшипников.

2) Облегченная конструкция:

Снижение веса подшипников: Оптимизация сочетания материалов и конструкции позволяет сократить использование ненужных металлов, добиться облегченного веса и адаптироваться к сценариям применения с высокими требованиями к весу.

3) Улучшение смазочных характеристик

Высокоэффективные смазочные материалы: Используйте консистентную смазку или смазочное масло, которые лучше подходят для работы в условиях высоких температур и высокого давления, чтобы обеспечить стабильную работу смазочного масла при длительной эксплуатации, тем самым снижая трение в подшипнике и повышая его долговечность.

4) Повышенная точность

Технология прецизионной обработки: Повышая точность изготовления и уменьшая погрешность между компонентами подшипника, обеспечивается более равномерный и стабильный контакт между игольчатым роликом и сепаратором. Это позволяет не только улучшить характеристики подшипника, но и продлить срок службы, а также снизить уровень шума и вибрации.

3. Основные области применения комбинированных игольчатых и упорных цилиндрических роликоподшипников QIBR

1) Ветроэнергетическое оборудование

Прецизионные радиальные подшипники типа PR могут также использоваться в качестве коренных подшипников, подшипников редукторов и т.д. в ветряных турбинах. Эти подшипники должны выдерживать огромные нагрузки и сохранять хорошие эксплуатационные характеристики в суровых условиях окружающей среды.

2) Промышленное оборудование

В области промышленного оборудования прецизионные радиальные подшипники типа PR широко используются в различных типах оборудования, таких как гидравлические системы, станки с ЧПУ, автоматизированные производственные линии, конвейерные ленты и т.д. Они могут обеспечить лучшую износостойкость, снизить затраты на обслуживание и повысить надежность механических систем.

3) Нефтегазовая промышленность

Прецизионные радиальные подшипники типа PR также играют важную роль в нефтяном бурении, морских платформах и оборудовании для добычи природного газа. Они должны работать в условиях экстремальных температур, давления и коррозионной среды.

4) Сельскохозяйственная техника

В сельскохозяйственной технике прецизионные радиальные подшипники типа PR используются в тракторах, зерноуборочных комбайнах, сеялках и другом оборудовании. Его износостойкость и коррозионная стойкость позволяют технике эффективно работать в тяжелых условиях.