Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Поиск нужной модель подшипника.

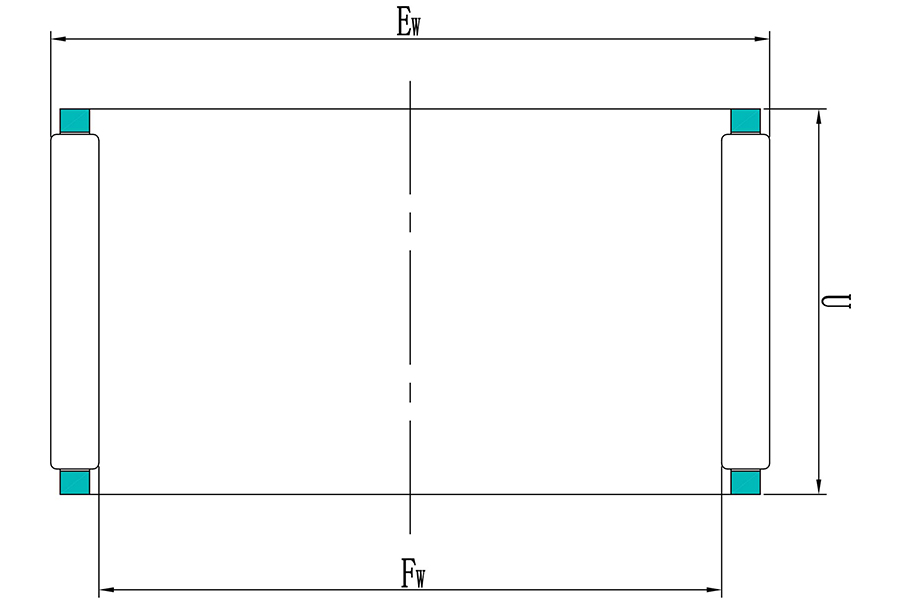

| NO. | Product | Product Number | Базовая динамическая нагрузка | Базовая статическая нагрузка | Диаметр под роликами (Fw) | Предел усталостной нагрузки (Pu) | Вес | Наружный диаметр дополнения игольчатого ролика (Ew) |

|---|---|---|---|---|---|---|---|---|

| 101 |

|

K 50x55x30 | 37.4 KN | 98 KN | 50 mm | 12 KN | 0.065 kg | 55 mm |

| 102 |

|

K 50x57x18 | 31.9 KN | 64 KN | 50 mm | 7.8 KN | 0.047 kg | 57 mm |

| 103 |

|

K 50x58x25 | 41.8 KN | 81.5 KN | 50 mm | 10.2 KN | 0.090 kg | 58 mm |

| 104 |

|

K 55x60x20 | 27 KN | 67 KN | 55 mm | 8.15 KN | 0.040 kg | 60 mm |

| 105 |

|

K 55x60x30 | 39.6 KN | 108 KN | 55 mm | 13.4 KN | 0.071 kg | 60 mm |

| 106 |

|

K 55x62x18 | 34.1 KN | 71 KN | 55 mm | 8.5 KN | 0.052 kg | 62 mm |

| 107 |

|

K 55x63x32 | 59.4 KN | 129 KN | 55 mm | 16.3 KN | 0.102 kg | 63 mm |

| 108 |

|

K 60x65x20 | 28.1 KN | 72 KN | 60 mm | 8.8 KN | 0.052 kg | 65 mm |

| 109 |

|

K 60x68x25 | 51.2 KN | 112 KN | 60 mm | 14 KN | 0.089 kg | 68 mm |

| 110 |

|

K 65x73x30 | 53.9 KN | 125 KN | 65 mm | 15.6 KN | 0.141 kg | 73 mm |

| 111 |

|

K 70x76x20 | 34.1 KN | 86.5 KN | 70 mm | 10.6 KN | 0.071 kg | 76 mm |

| 112 |

|

K 70x78x30 | 57.2 KN | 137 KN | 70 mm | 17 KN | 0.148 kg | 78 mm |

| 113 |

|

K 75x83x23 | 47.3 KN | 110 KN | 75 mm | 13.7 KN | 0.124 kg | 83 mm |

| 114 |

|

K 80x88x30 | 68.2 KN | 176 KN | 80 mm | 22 KN | 0.138 kg | 88 mm |

| 115 |

|

K 85x92x20 | 42.9 KN | 108 KN | 85 mm | 13.2 KN | 0.102 kg | 92 mm |

| 116 |

|

K 90x97x20 | 42.9 KN | 114 KN | 90 mm | 13.7 KN | 0.109 kg | 97 mm |

| 117 |

|

K 90x98x30 | 64.4 KN | 173 KN | 90 mm | 21.6 KN | 0.172 kg | 98 mm |

| 118 |

|

K 95x103x30 | 66 KN | 180 KN | 95 mm | 22.8 KN | 0.165 kg | 103 mm |

| 119 |

|

K 100x108x27 | 55 KN | 143 KN | 100 mm | 17.6 KN | 0.185 kg | 108 mm |

Особенности и преимущества игольчатых подшипников в сборе с сепаратором

Игольчатые подшипники в сборе с сепаратором QIBR решают ряд важнейших проблем в различных областях, в основном в следующих областях:

1. Компактная конструкция

Использование игольчатых роликов в качестве тел качения позволяет этим подшипникам воспринимать большие радиальные нагрузки при относительно небольших размерах, что делает их пригодными для установки в ограниченном пространстве, особенно в компактных механических конструкциях.

2. Низкое трение и высокая эффективность

Благодаря точной конструкции между игольчатыми роликами и сепаратором, эти подшипники имеют низкие потери на трение, что снижает тепловыделение и повышает эффективность работы. Это делает их пригодными для использования в высокоскоростных и высокопроизводительных средах.

3. Высокая долговечность

Сепаратор стабилизирует положение игольчатых роликов, уменьшая контакт и износ между ними, тем самым увеличивая срок службы подшипника. Правильный зазор и прецизионная конструкция обеспечивают стабильность и надежность в процессе эксплуатации.

4. Низкий уровень шума и вибрации

Рациональная структура между игольчатыми роликами и сепаратором минимизирует контакт между роликами, снижая уровень шума и вибрации, что делает их идеальными для сред, требующих низкого уровня шума.

5. Адаптация к высокоскоростным применениям

Благодаря малой форме игольчатых роликов и уменьшенной площади контакта, эти подшипники хорошо подходят для высокоскоростных применений, эффективно предотвращая чрезмерное трение и перегрев на высоких скоростях.

Улучшение характеристик и решения для игольчатых подшипников в сборе с сепаратором QIBR

1. Улучшенные материалы

Выбор высокопроизводительных материалов: Использование материалов с повышенной твердостью, износостойкостью и коррозионной стойкостью может значительно повысить долговечность и стабильность подшипника.

2. Оптимизированная конструкция сепаратора

Структурная оптимизация: Улучшение структуры сепаратора для достижения лучшего расположения игольчатых роликов и равномерного распределения нагрузки. Оптимизация сепаратора уменьшает столкновения игольчатых роликов, повышая стабильность и эффективность работы.

Уменьшение площади контакта: Благодаря улучшению геометрии сепаратора и расположению игольчатых роликов площадь контакта между роликами сводится к минимуму, что снижает трение и износ.

3. Улучшенные характеристики смазки

Эффективные смазочные материалы: Использование консистентных смазок или масел, подходящих для работы в условиях высоких температур и высокого давления, обеспечивает стабильную работу смазочного материала при длительной эксплуатации, снижая трение и повышая долговечность.

4. Повышенная точность

Точная обработка: Повышение точности изготовления сводит к минимуму погрешности между компонентами подшипника, обеспечивая более равномерный и стабильный контакт между игольчатыми роликами и сепаратором. Это улучшает эксплуатационные характеристики, продлевает срок службы, снижает уровень шума и вибрации.

Основные области применения игольчатых подшипников QIBR в сборе с сепаратором

1. Трансмиссии

Игольчатые подшипники в сборе с сепаратором обычно используются между шестернями и валами внутри трансмиссий для повышения эффективности трансмиссий и уменьшения габаритов.

2. Промышленное оборудование

Коробки передач и трансмиссионные системы: Широко используемые в редукторах и системах с зубчатым приводом, эти подшипники способны выдерживать большие радиальные нагрузки, уменьшать занимаемое пространство и повышать эффективность трансмиссии.

Оборудование для автоматизации: В автоматизированных производственных линиях игольчатые подшипники в сборе с сепаратором QIBR поддерживают вращающиеся компоненты, обеспечивая точность и стабильность оборудования.

3. Авиационные двигатели

Турбинные валы и вращающиеся компоненты: В авиационных двигателях игольчатые подшипники QIBR используются в турбовалах, турбинах и других вращающихся компонентах для обеспечения плавной работы на высоких скоростях при восприятии радиальных нагрузок, возникающих при высокоскоростном вращении.

4. Бытовая техника

Бытовая техника: Игольчатые подшипники в сборе с сепаратором QIBR широко используются в таких изделиях, как стиральные машины, электрические вентиляторы, электроинструменты и двигатели, обеспечивая высокую эффективность и стабильность при сокращении занимаемого пространства.