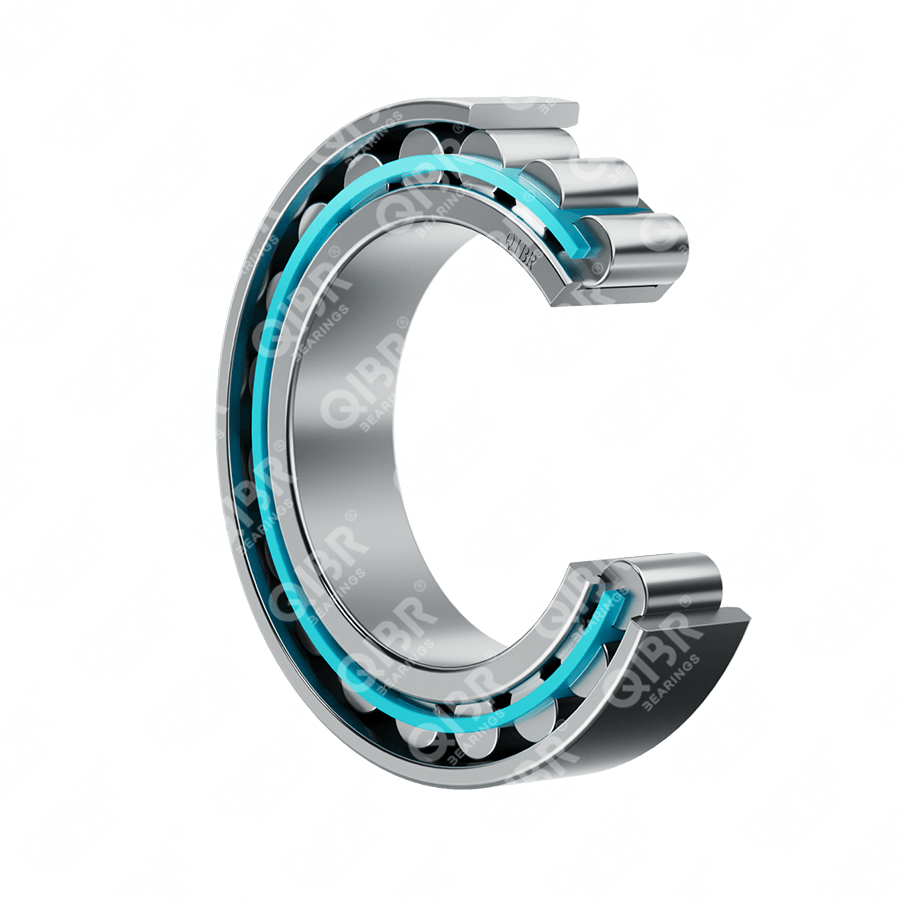

NU 328 ECM

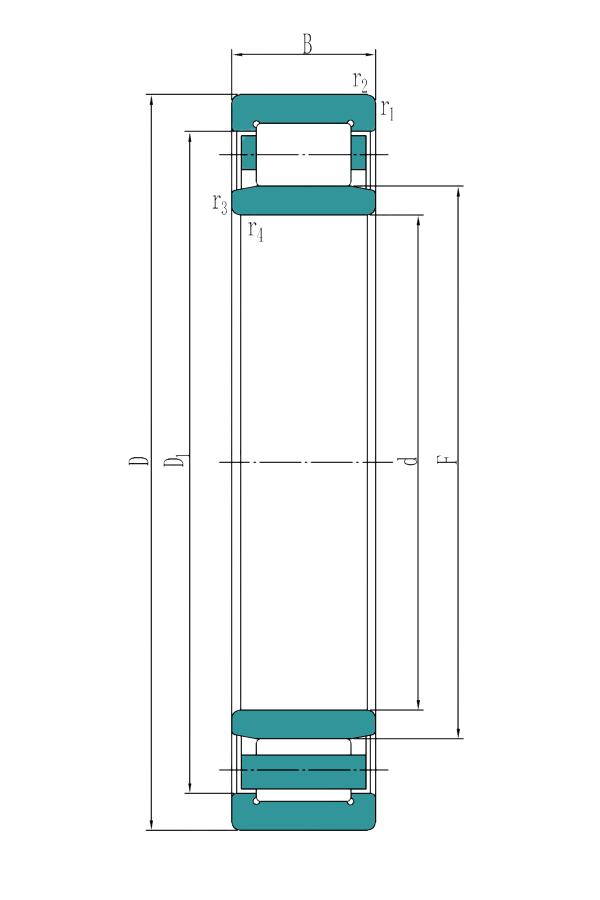

- Внутренний диаметр:

- 140 mm

- Наружный диаметр:

- 300 mm

- Ширина:

- 62 mm

- Масса :

- 22.5 Kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - NU 328 ECM

Описание

NU 328 ECM Особенности и преимущества цилиндрических роликоподшипников

Высокая грузоподъемность: Спроектирован с высокой радиальной грузоподъемностью, подходит для тяжелых нагрузок и ударных нагрузок, что делает его идеальным для условий высокой нагрузки.

Низкий коэффициент трения: Линейный контакт между роликами и дорожками качения обеспечивает низкий коэффициент трения, что делает его пригодным для работы на высоких скоростях.

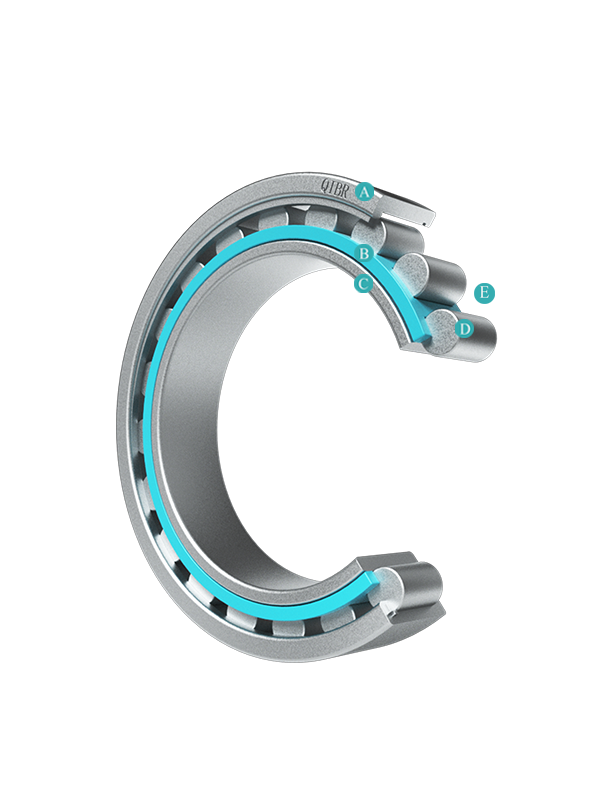

Разделяемая конструкция: Внутреннее и внешнее кольца могут быть разделены, что облегчает монтаж и демонтаж, идеально подходит для оборудования, требующего частого обслуживания.

Высокая адаптивность: Способны выдерживать изменения относительного положения из-за теплового расширения или ошибок при монтаже, подходят для использования в качестве подшипника свободного конца.

Применение: Широко используется в автомобильной промышленности, промышленном оборудовании, двигателях и энергетическом оборудовании, бытовой технике, аэрокосмической промышленности, медицинском оборудовании, железных дорогах и транспорте, строительной технике, ветровой энергии и возобновляемых ресурсах.

QIBR - NU 328 ECM Оптимизация цилиндрических роликовых подшипников

Возможность выбора уровней точности, вибрации и шума: Опции включают P6, P5 для точности, V2, V3 для вибрации и Z2, Z3 для шума.

Материал сепаратора: Материал сепаратора может быть выбран в зависимости от условий эксплуатации: сталь, латунь или нейлон.

Замена смазки: Выберите смазку в соответствии с рабочими требованиями подшипника, например, SKF LGMT 2, Timken GR217 или Shell Gadus S2 V220AC.

Оптимизированный профиль ролика: В зависимости от условий эксплуатации, логарифмические кривые профиля могут использоваться для оптимизации профиля ролика, уменьшая концентрацию напряжений между роликами и дорожками качения, повышая грузоподъёмность и срок службы.

Больше возможностей для настройки: QIBR может спроектировать и оптимизировать подшипники в соответствии с чертежами заказчика и условиями эксплуатации.

QIBR - NU 328 ECM Контроль качества цилиндрических роликовых подшипников

Измерение размеров: Различные высокоточные приборы используются для измерения различных размеров подшипника с точностью до 0,001 мм.

Точность вращения: Циферблатный калибр измеряет незначительные дефекты или отклонения поверхности, точность измерения достигает 0,001 мм.

Измерение твердости: Твердость поверхности измеряется с помощью твердомера с точностью ±0,5HRC.

Металлографический анализ: Внутренняя металлографическая структура анализируется с помощью профессионального металлографического микроскопа.

Геометрический допуск: Контурный калибр измеряет геометрическую форму и относительное положение подшипника.

Контроль шума: Виброметр отслеживает вибрацию во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Благодаря усилению конструкции, использованию тел качения с логарифмическим профилем и внутренней оптимизации подшипник приобретает такие преимущества, как высокая грузоподъемность, низкий коэффициент трения, минимизация сопротивления, что приводит к значительному увеличению срока службы подшипника и снижению затрат на обслуживание.

Скачать