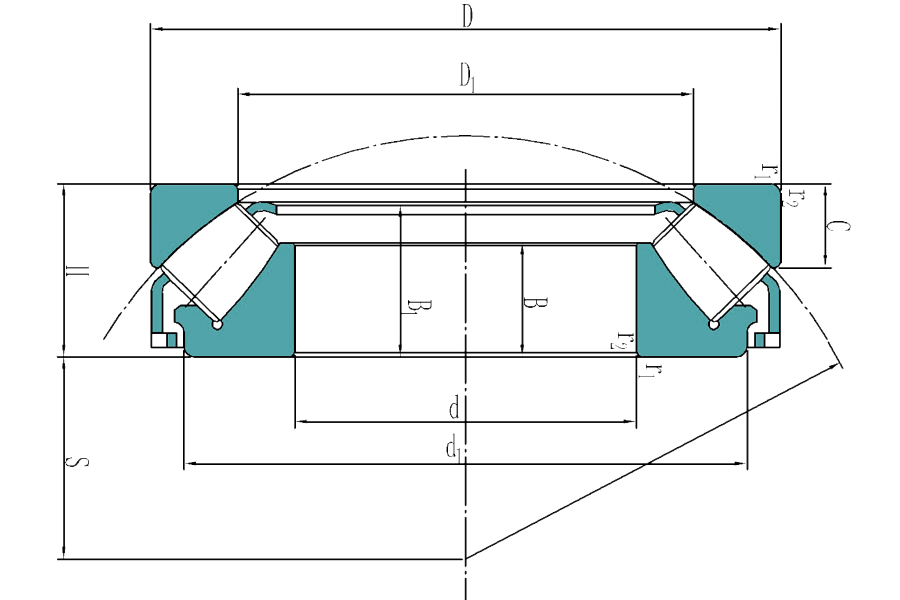

294/950 EF

- Внутренний диаметр:

- 950 mm

- Наружный диаметр:

- 1600 mm

- Ширина:

- 390 mm

- Масса :

- 3070 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - 294/950 EF

Описание

294/950 EF Особенности и преимущества упорных роликовых подшипников

Допустимая погрешность смещения: Упорные роликоподшипники обладают способностью к самоустановке, что позволяет им выдерживать погрешности смещения.

Грузоподъемность: Отличное прилегание роликов к дорожке качения позволяет подшипнику выдерживать большие осевые нагрузки и одновременно воспринимать некоторые радиальные нагрузки.

Высокоскоростная способность: Конструкция сепаратора и хорошее прилегание роликов к дорожке качения делают эти подшипники пригодными для работы на относительно высоких скоростях.

Низкое трение: Оптимизация контакта на торцевых поверхностях роликов позволяет поддерживать тепловыделение при трении на низком уровне во время работы на высоких скоростях.

Длительный срок службы: Специальный профиль роликов снижает краевые напряжения в местах контакта роликов с дорожкой качения.

Применение: Упорные роликовые подшипники широко используются в станкостроении, аэрокосмической промышленности, металлургии и горнодобывающей промышленности, тяжелом машиностроении, автомобильной промышленности, сельскохозяйственной технике и энергетическом оборудовании.

QIBR - 294/950 EF Оптимизация упорных роликовых подшипников

Высокопроизводительные материалы: Подходящие материалы могут быть выбраны в соответствии с требованиями заказчика, например, 52100, 100Cr6, SUJ2 и т.д.

Выбор сепаратора: Клиенты могут выбрать сепаратор из различных материалов в зависимости от своих потребностей, включая обработанные латунные сепараторы, штампованные стальные оконные сепараторы и обработанные медные сепараторы.

Выбор смазки: Смазочные материалы могут быть выбраны в соответствии с эксплуатационными требованиями подшипников, например, SKF LGET 2 или Shell Gadus S5 V142W 00.

Дополнительная персонализация: QIBR может разработать и оптимизировать упорные шарикоподшипники в соответствии с условиями эксплуатации и требованиями заказчика.

QIBR - 294/950 EF Контроль качества упорных роликовых подшипников

Измерение размеров: Для измерения различных размеров подшипников используются различные высокоточные приборы, достигающие максимальной точности 0,001 мм.

Точность вращения: Небольшие дефекты поверхности или отклонения измеряются микрометром с точностью измерения до 0,001 мм.

Измерение твердости: Твердость поверхности измеряется с помощью твердомера с точностью до ±0,5HRC.

Металлографический анализ: Внутренняя металлографическая структура металлов анализируется с помощью профессионального металлографического микроскопа.

Геометрический допуск: Геометрия и относительное положение подшипника измеряются с помощью профильного проектора.

Мониторинг шума: Вибрация во время работы контролируется с помощью виброметра для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Высокая несущая способность, возможность смещения, разъемная конструкция

Скачать