32968

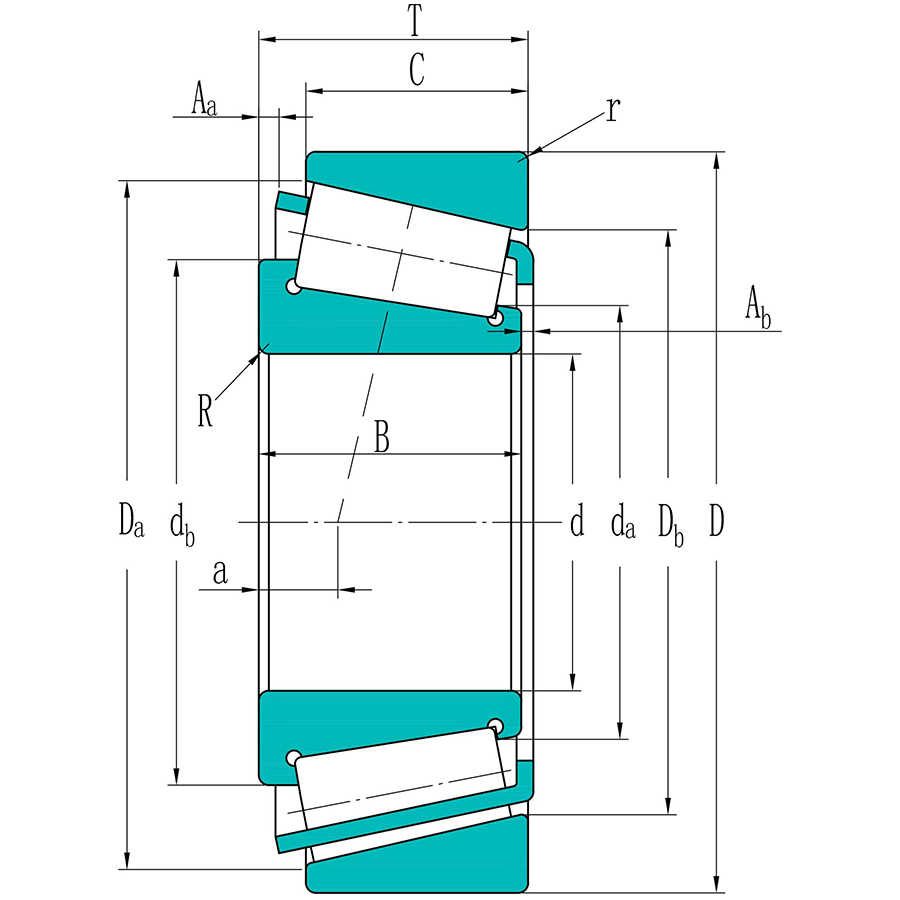

- Внутренний диаметр:

- 340 mm

- Наружный диаметр:

- 460 mm

- Ширина:

- 76 mm

- Масса :

- 34.46 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - 32968

Описание

QIBR - 32968 Конический Роликовый Подшипник Advantages and Applications

32968 Конический Роликовый Подшипник, high load-bearing capacity, high rigidity, Bore is 340 mm, Cup outer diameter (D) is 460 mm, Bearing width (T) is 76 mm, Weight is 34.46 kg, suitable for wheelsets and axle boxes of locomotives, gearboxes and harvesters, etc., and is the most widely used bearing in working conditions with high load-bearing capacity requirements.

QIBR - 32968 Конический Роликовый Подшипник Characteristics

32968 Конический Роликовый Подшипник, long life, easy installation and maintenance, strong adaptability. 32968 Конический Роликовый Подшипник, can withstand radial load, certain axial load and overturning moment, suitable for mechanical equipment with high durability requirements.

32968 Особенности и преимущества конических роликовых подшипников

Высокая грузоподъемность: Конические роликоподшипники выдерживают значительные радиальные и осевые усилия, что делает их особенно подходящими для восприятия комбинированных нагрузок. Осевая грузоподъемность зависит от угла контакта; чем больше угол контакта, тем больше осевая грузоподъемность.

Высокая точность: Эти подшипники изготавливаются с использованием шлифовальных процессов, что обеспечивает высокую точность, которая необходима для применений, требующих строгих стандартов.

Регулируемый зазор: При установке зазор может быть отрегулирован путем изменения взаимного расположения внутреннего и наружного колец, что оптимизирует рабочие характеристики.

Хорошая жесткость и ударопрочность: Компактная структура конических роликовых подшипников обеспечивает отличную жесткость и превосходную ударопрочность.

Применение: Они широко используются в таких областях, как редукторы, подъемное оборудование, прокатные станы, автомобильная промышленность, металлургия, нефтяная промышленность, горное оборудование, машиностроение и аэрокосмическая промышленность.

QIBR - 32968 Оптимизация конических роликовых подшипников

Термообработка: Процесс производства оптимизирован за счет мартенситной закалки (стандарт) и поверхностной закалки термообработки.

Тип сепаратора: Тип сепаратора выбирается в зависимости от требований заказчика и условий эксплуатации, включая такие варианты, как штампованные сепараторы, сепараторы из PA66, армированного стекловолокном, и сепараторы из PEEK.

Специальные варианты: Для особых требований к применению предлагаются подшипники с твердым маслом, изолированные подшипники INSOCOAT и подшипники с износостойким покрытием NoWear.

Больше возможностей для настройки: QIBR может спроектировать и оптимизировать подшипники, основываясь на чертежах и производственных потребностях заказчика.

QIBR - 32968 Контроль качества конических роликовых подшипников

Измерение размеров: Для измерения различных размеров подшипников используются различные высокоточные приборы, достигающие максимальной точности 0,001 мм.

Точность вращения: Для измерения незначительных дефектов и отклонений поверхности используется циферблатный манометр с точностью измерения до 0,001 мм.

Измерение твердости: Твердость поверхности измеряется с помощью твердомера с точностью ±0,5 HRC.

Металлографический анализ: Профессиональные металлографические микроскопы используются для анализа внутренней металлографической структуры металла.

Геометрический допуск: Профилемер измеряет геометрическую форму и относительное положение подшипников.

Мониторинг шума: Устройства контроля вибрации оценивают условия вибрации во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

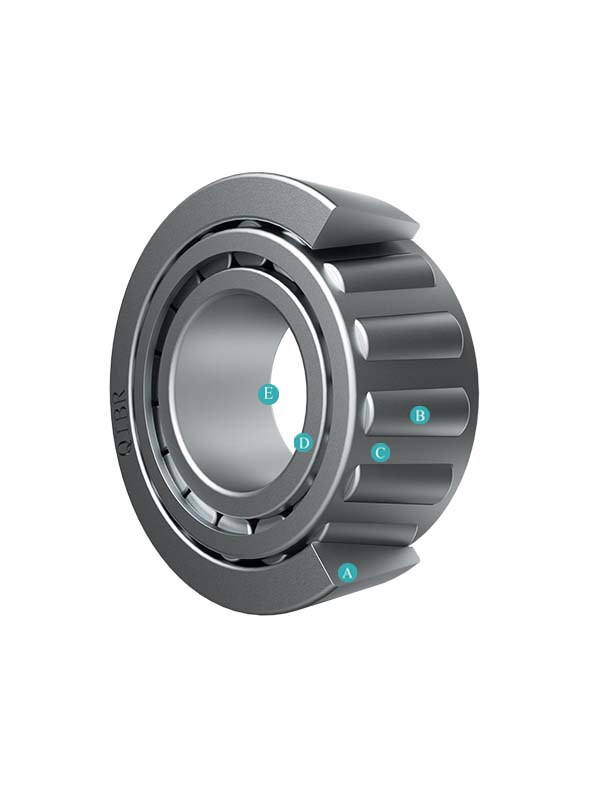

Конические роликоподшипники обычно являются разъемными, то есть узел конического внутреннего кольца, состоящий из внутреннего кольца с роликами и сепаратора, может быть установлен отдельно от конического наружного кольца (наружного кольца).

Скачать