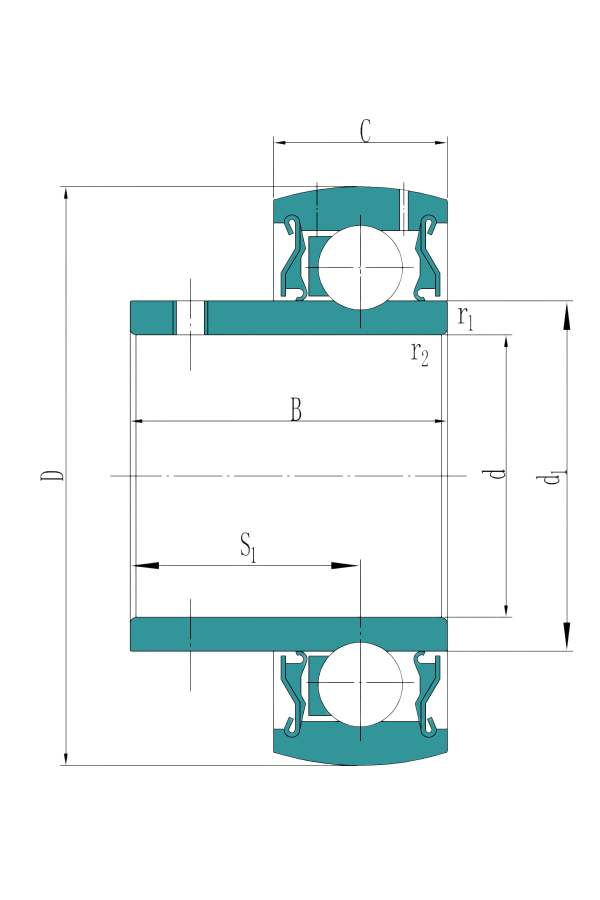

UC208

- Внутренний диаметр:

- 40 mm

- Наружный диаметр:

- 80 mm

- Ширина:

- 49.2 mm

- Масса :

- 0.60 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - UC208

Описание

UC208 Характеристики и преимущества подшипников для корпуса

Модульная конструкция: Модульная конструкция облегчает прямую установку и замену, повышая эффективность работы оборудования.

Высокая адаптивность: Подшипники для корпуса могут воспринимать как радиальные, так и осевые нагрузки, демонстрируя значительную способность к восприятию несоосности.

Множество механизмов фиксации: Эти подшипники оснащены различными механизмами фиксации для удовлетворения различных требований к установке.

Экономичность: Оптимизируя эффективность вращающихся компонентов, подшипники для корпуса снижают частоту технического обслуживания и замены, снижая эксплуатационные расходы.

Применение: Они широко используются в таких отраслях, как сельскохозяйственная техника, автомобилестроение, железнодорожная промышленность, горнодобывающая и металлургическая промышленность, пищевое оборудование, логистическое транспортное оборудование и текстильное оборудование.

QIBR - UC208 Оптимизация подшипников для корпуса

Оптимизация технологического процесса: Параметры обработки, такие как скорость резания и подача, оптимизируются на основе требований заказчика к производительности подшипника.

Высокопроизводительные материалы: Материалы подшипников могут быть заменены в соответствии с различными условиями работы, например, нержавеющая сталь или подшипниковая сталь.

Дополнительная персонализация: QIBR может разработать и оптимизировать подшипники в соответствии с условиями эксплуатации и требованиями заказчика.

QIBR - UC208 Контроль качества подшипников для корпуса

Измерение размеров: Для измерения различных размеров подшипника используется несколько высокоточных приборов с точностью до 0,001 мм.

Точность вращения: Микрометр измеряет небольшие дефекты или отклонения поверхности с точностью измерения до 0,001 мм.

Измерение твердости: Твердомер измеряет поверхностную твердость подшипников с точностью ±0,5HRC.

Металлографический анализ: Профессиональные металлографические микроскопы анализируют внутреннюю металлографическую структуру металлов.

Геометрические допуски: Профильный проектор измеряет геометрическую форму и относительное положение подшипников.

Контроль шума: Виброметры контролируют условия вибрации во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали поставляются от поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Вставные подшипники с упорными винтами предназначены для надежной и простой установки на валы. Резьбовые винты обеспечивают плотную посадку, предотвращая проскальзывание и гарантируя надежную работу во вращающихся системах, что делает их идеальными для оборудования, где важна стабильность и точная центровка.

Скачать