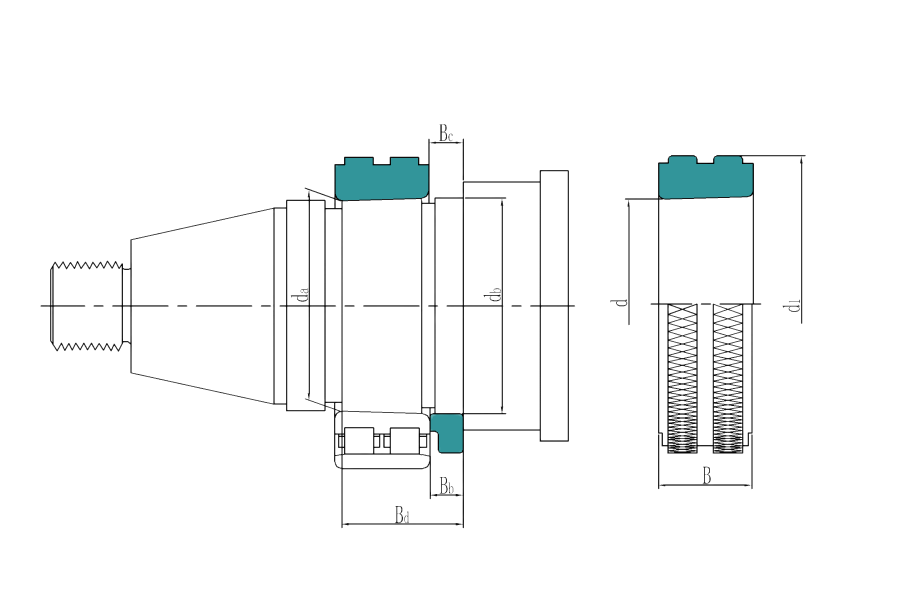

GRA 3015

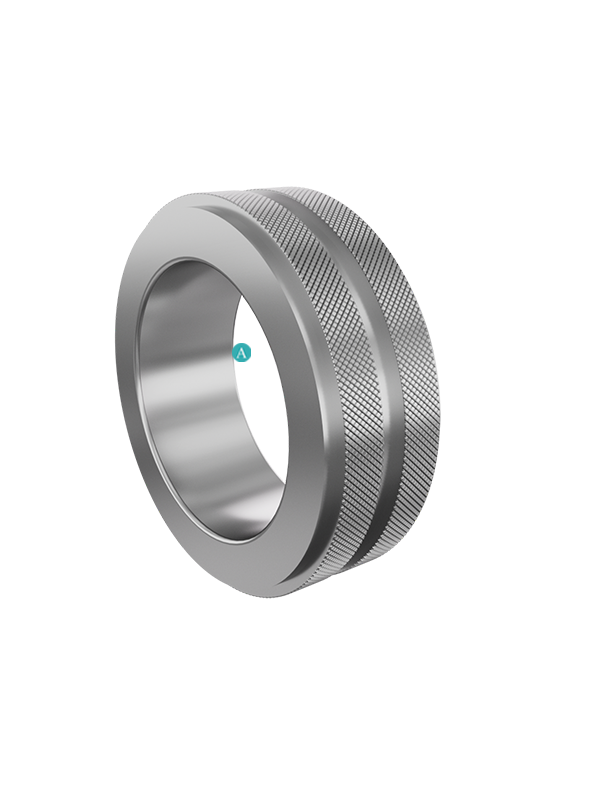

- Внутренний диаметр:

- 75 mm

- Наружный диаметр:

- 100 mm

- Ширина:

- 30 mm

- Масса :

- 0.73 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - GRA 3015

Описание

GRA 3015 GRA 30 Ring Gauge Characteristics and Advantages

High Precision: Utilizes advanced measurement technology, achieving a measurement accuracy of up to 0.001 mm.

Drop Prevention: The outer steel sleeve acts as a protective ring, preventing the gauge from breaking upon dropping.

User-Friendly: Designed to minimize slipping, allowing for hand operation, which enhances work efficiency. Dirt does not adhere to the instrument.

Good Repeatability: Multiple measurements of the same bearing inner ring yield consistent results, demonstrating high repeatability.

Application: Widely used in the manufacturing, maintenance, and quality inspection of cylindrical parts.

QIBR - GRA 3015 GRA 30 Ring Gauge Optimization

High-performance materials: Different materials can be selected based on customer needs, such as tungsten steel, ceramics, or steel.

Accuracy: Precision grades can be chosen based on the operational conditions of the workpiece, such as 6g, 6h, 6f, 8g grades, etc.

More customization: QIBR can design and optimize bearings according to customer needs and operating conditions.

QIBR - GRA 3015 GRA 30 Ring Gauge Quality Control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the GRA30 ring gauge, achieving a maximum precision of 0.001 mm.

Hardness measurement: The surface hardness of the GRA30 ring gauge is measured using a hardness tester, with a measurement precision of ±0.5HRC.

Metallographic Analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Raw material control: Procurement of steel and parts from ISO 14001 certified suppliers ensures product stability while promoting sustainable development.

Особенности и преимущества

Серия GRA 30 обычно используется для проверки посадочных мест конических валов цилиндрических роликовых подшипников серии NN 30K.

Скачать