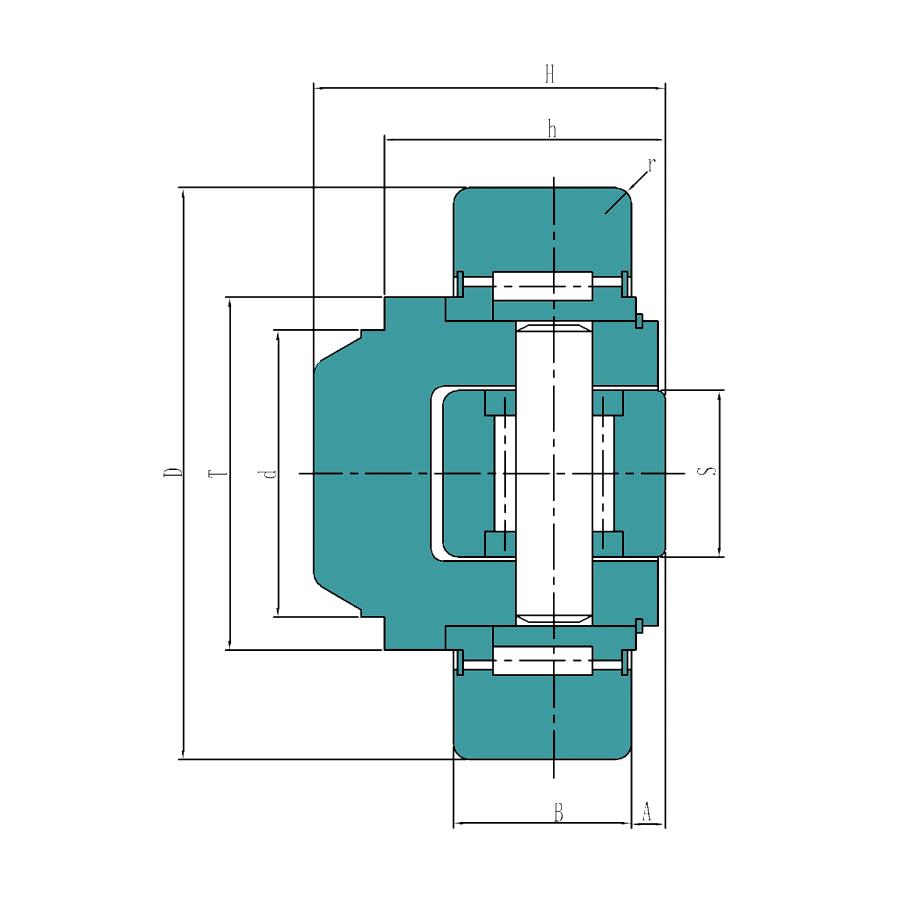

4.055 HT

- Наружный диаметр:

- 70.1 mm

- Ширина:

- 44 mm

- Масса :

- 0.85 kg

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - 4.055 HT

Описание

4.055 HT Особенности и преимущества комбинированных подшипников

Высокая грузоподъемность: Обеспечивает большую несущую способность в радиальном и осевом направлениях, эффективно продлевая срок службы подшипника.

Интегрированная конструкция: Обеспечивает большую несущую способность в радиальном и осевом направлениях, эффективно продлевая срок службы подшипника.

Компактность: Компактная конструкция уменьшает требуемое пространство для установки за счет интеграции нескольких функций.

Композитная грузоподъемность: Способна выдерживать нагрузки в нескольких направлениях, обеспечивая стабильную работу при высоких нагрузках и высоких скоростях.

Применение: Широко используется в таких областях, как портальные подъемные системы, портальные рамы вилочных погрузчиков, автомобильная промышленность, станкостроение, медицинское оборудование и мобильные системы перемещения.

QIBR - 4.055 HT Оптимизация комбинированных подшипников

Высокопроизводительные материалы: Материалы для подшипников могут быть выбраны в зависимости от условий эксплуатации и требований заказчика, включая легированную сталь, керамику и комбинации керамических шариков со стальными дорожками качения.

Выбор смазки: Смазка может быть выбрана в соответствии с требованиями заказчика, например, NSK LGHP 2 или Mobilith SHC 220.

Варианты покрытий: Подходящие покрытия могут быть выбраны в зависимости от требований заказчика и условий работы, например, PTFE для защиты от трения, хром для износостойкости и цинково-никелевый сплав для защиты от коррозии.

Различные типы: Комбинированные подшипники могут быть выбраны в зависимости от требований заказчика и условий эксплуатации, например, игольчатые подшипники без внутренних колец в сочетании с упорными шарикоподшипниками или подшипниками с крышками.

Больше возможностей для настройки: QIBR может разработать и оптимизировать комбинации подшипников и материалов на основе чертежей заказчика и условий эксплуатации.

QIBR - 4.055 HT Контроль качества комбинированных подшипников

Измерение размеров: Различные высокоточные приборы используются для измерения различных размеров подшипников, достигая максимальной точности 0,001 мм

Точность вращения: Для измерения небольших дефектов или отклонений поверхности используется циферблатный калибр, точность измерения составляет 0,001 мм.

Измерение твердости: Твердость измеряется с помощью твердомера с точностью ±0,5HRC.

Металлографический анализ: Профессиональные металлографические микроскопы используются для анализа внутренней металлографической структуры металлов.

Геометрические допуски: Для измерения геометрической формы и относительного положения подшипников используется профильный проектор.

Контроль шума: Виброметры контролируют вибрацию во время работы для получения данных о шуме.

Контроль сырья: Сталь и детали закупаются у поставщиков, сертифицированных по стандарту ISO 14001, что обеспечивает стабильность продукции и способствует устойчивому развитию.

Особенности и преимущества

Эти подшипники обладают большой радиальной и осевой грузоподъемностью и отличаются высокой степенью заменяемости, что делает их идеальными для использования в широком спектре оборудования, требующего высокой грузоподъемности и упрощенного монтажа.

Скачать