QACB30.1541.8H7

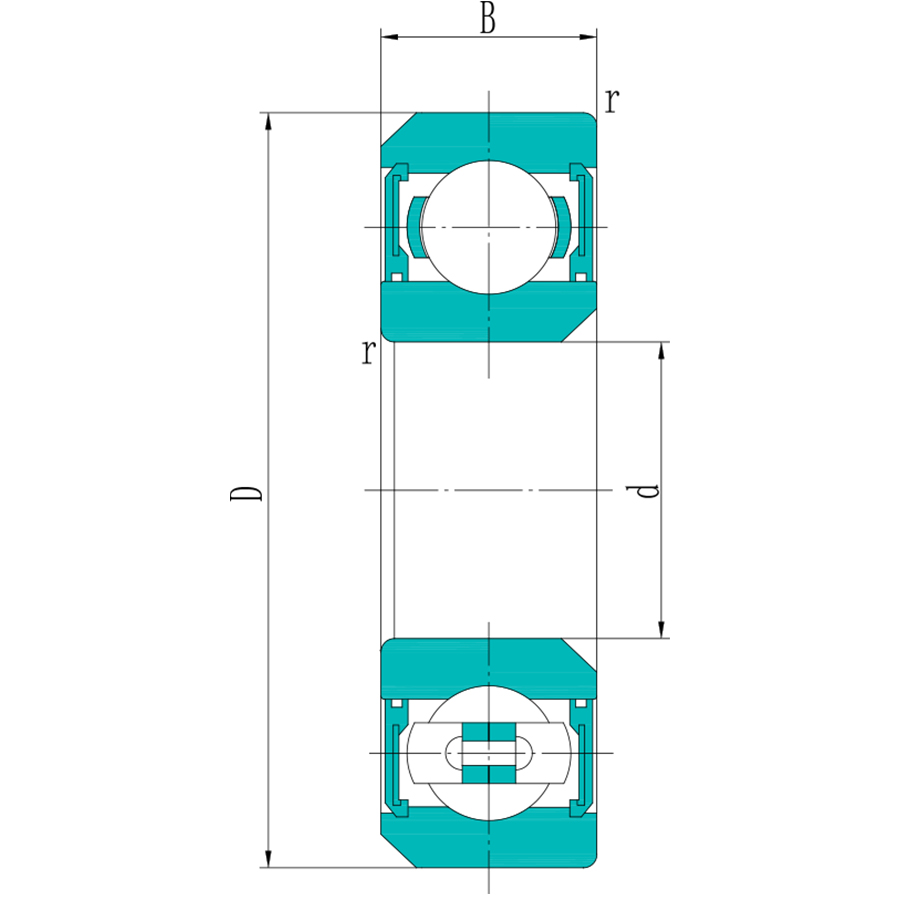

- Наружный диаметр (D)

- 41.8 mm

- Внутренний диаметр (d)

- 30.15 mm

- Габаритная ширина (B)

- 7 mm

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - QACB30.1541.8H7

Описание

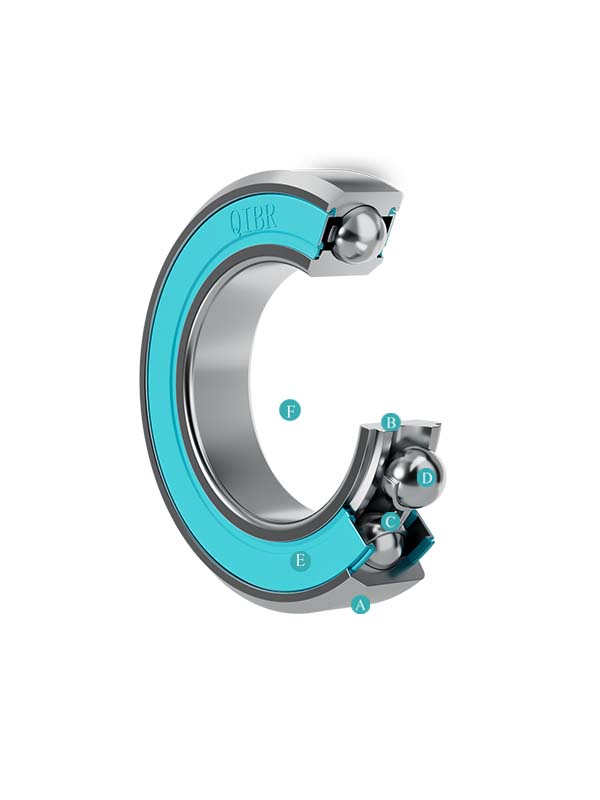

QACB30.1541.8H7 Bicycle Bearing Product Product Features and Advantages

Reduced Friction: Capable of simultaneously bearing large radial and axial loads, suitable for various load conditions.

Durability: Made from wear-resistant materials, capable of withstanding heavy loads while significantly reducing rotational resistance under load conditions.

Lightweight Design: Low-density design reduces the overall weight of the bicycle, enhancing handling and riding comfort.

Precise Steering: Low friction coefficient, resulting in low noise during operation, suitable for high-speed applications.

Application: Widely used in key parts such as wheels, bottom brackets, pedals, frames, derailleurs, sports and racing bicycles, and electric bicycles.

QIBR - QACB30.1541.8H7 Bicycle Bearing Optimization

Modular Design: Bearings are designed modularly according to customer needs, making replacement and maintenance easier.

High-Performance Materials: Lubricants can be chosen based on bearing operational needs, such as SKF LGED 2, Mobil SHC Polyrex 102 EM, etc.

Sealing Materials: Different sealing materials can be chosen based on customer needs, such as rubber, POM, polyurethane, etc.

Lubricants: Suitable lubricants are selected based on bearing working conditions and different bearing locations, such as SKF LGLT 2, Klüber ISOFLEX TOPAS NB 52, Multemp SRL, etc.

Further Customization: QIBR can design and optimize bearings based on customer working conditions and requirements.

QIBR - QACB30.1541.8H7 Bicycle Bearing Quality Control

Dimension measurement: Multiple professional high-precision instruments are used to measure various dimensions of the bearing, with the highest precision reaching 0.001mm.

Rotation accuracy: A dial indicator is used to measure minor defects or deviations on the bearing surface, with measurement accuracy up to 0.001mm.

Hardness measurement: The surface hardness of the bearing is measured with a hardness tester, with measurement accuracy up to ±0.5 HRC.

Metallographic analysis: The internal metallographic structure of the metal is analyzed using a professional metallographic microscope.

Geometric tolerance: A contour instrument is used to measure the geometric shape and relative position of the bearing.

Noise monitoring: Vibration instruments are used to monitor vibration during operation and obtain noise data.

Raw material control: Steel and parts are procured from suppliers with ISO 14001 certification, ensuring product stability while promoting sustainable development.

Особенности и преимущества

Велосипедные подшипники - это важнейшие компоненты, обеспечивающие плавное вращение различных частей велосипеда, таких как колеса, нижний кронштейн, гарнитура и педали. Они уменьшают трение и износ между движущимися частями, обеспечивая эффективную передачу энергии и комфортную езду. Подшипники бывают разных типов, включая шариковые, роликовые и картриджные, каждый из которых подходит для определенных целей. Правильное обслуживание и смазка имеют решающее значение для продления срока их службы и обеспечения оптимальной производительности. Выбор правильного типа и качества подшипника может существенно повлиять на эффективность и долговечность велосипеда.

Скачать