Newsroom

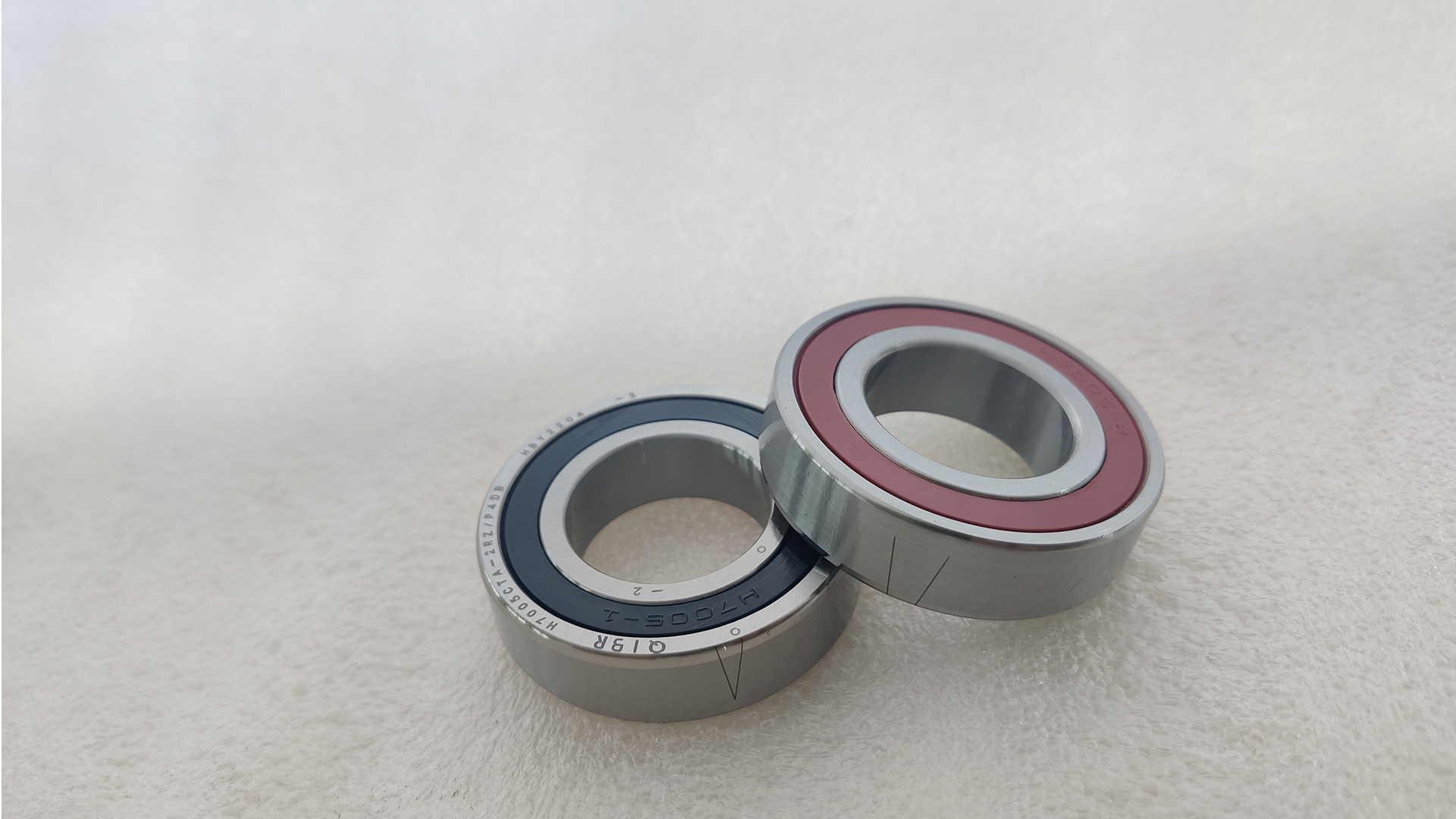

Как обеспечить бесшумную работу подшипников?

2024-08-01Шум в высокоточных радиально-упорных шарикоподшипниках может быть вызван различными факторами, почти все из которых связаны с вибрацией. Мы расскажем, как такие факторы, как изготовление подшипников, соблюдение допусков и выбор смазки, могут влиять на уровень вибрации и шума подшипников.

Во-первых, ненормальный шум в высокоточных радиально-упорных шарикоподшипниках обычно связан с повреждением подшипника. Чрезмерный шум - самый простой метод определения повреждения подшипника. Однако как быть с подшипниками в других областях применения? Если высокоточный радиально-упорный шарикоподшипник не поврежден, значит ли это, что шума нет, или шум подшипника допустим?

Дорожки и тела качения подшипников не бывают идеально круглыми. Даже при тщательной тонкой шлифовке и полировке тела качения и дорожки качения никогда не будут абсолютно гладкими. Эти недостатки могут вызвать ненужную вибрацию, которая может повредить высокоточные радиально-упорные шарикоподшипники в течение их срока службы.

1. Факторы, вызывающие вибрацию и шум подшипника, включают:

Грубые или поврежденные тела качения или дорожки качения

Плохая округлость шариков или дорожек каченияPoor округлость шариков или дорожек качения

Внутреннее загрязнение подшипника

Неправильные допуски вала или корпуса

Неправильный радиальный зазорRough or damaged rolling elements or raceways

2. Влияние изготовления подшипника на уровень шума

Малошумные подшипники отличаются превосходной чистотой поверхности шариков и дорожек качения. При изготовлении строго контролируется округлость шариков и дорожек качения. Плавность или бесшумность работы подшипника можно проверить с помощью акселерометра, который измеряет вибрацию подшипника на наружном кольце, обычно при вращении внутреннего кольца со скоростью 1800 об/мин.

Другой метод контроля шума - указать радиальный зазор, чтобы подшипник имел практически нулевой радиальный зазор при работе. Если допуски на вал или корпус неправильные, подшипник может быть слишком тугим, что приведет к повышенному шуму. Аналогичным образом, недостаточная округлость вала или корпуса может деформировать дорожки подшипника, влияя на вибрацию и шум подшипника.

3. Влияние допустимой посадки подшипника на шум

Посадка подшипника - еще один важный фактор, который необходимо учитывать. Плохая посадка может привести к образованию вмятин на дорожках подшипника, что значительно увеличит вибрацию. Аналогичным образом, загрязнения в подшипнике также могут вызвать ненужную вибрацию.

4. Влияние смазочных материалов на уровень шума

Для поддержания низкого уровня шума подшипники должны быть свободны от загрязняющих веществ. Если подшипники используются в не очень чистых средах, необходимо предусмотреть защиту от пыли, например, контактные уплотнения.

Для высококачественных подшипников также рекомендуется использовать малошумные смазочные материалы. Эти смазки с тонкой фильтрацией обеспечивают бесшумную работу подшипника, так как не содержат крупных твердых частиц.

Для получения дополнительной информации обращайтесь в компанию QIBR