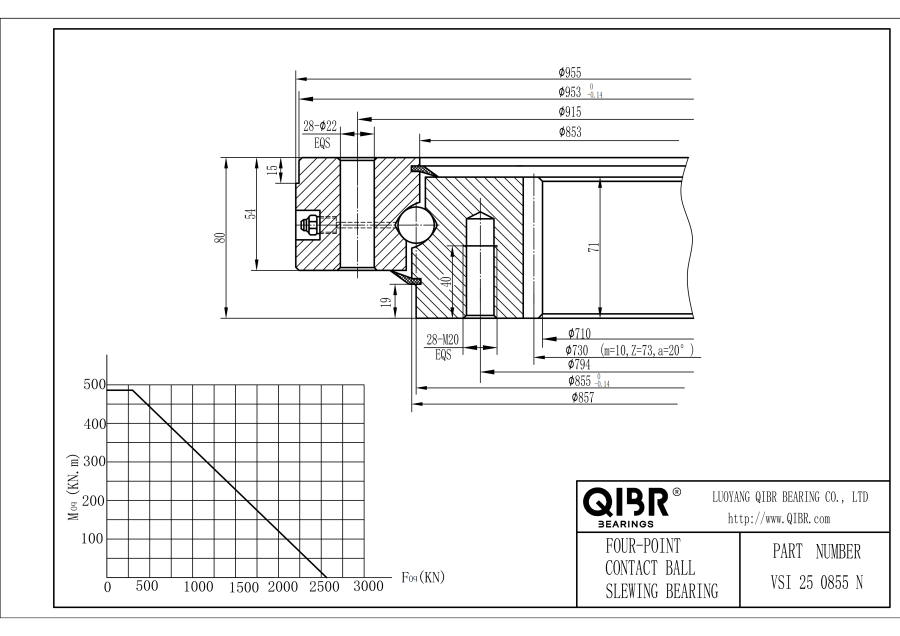

VSI 25 0855 N

- Внутренний диаметр:

- 710 mm

- Наружный диаметр:

- 955 mm

- Ширина:

- 56 mm

- Масса :

- 137 kg

Мы предложим вам самое подходящее решение.

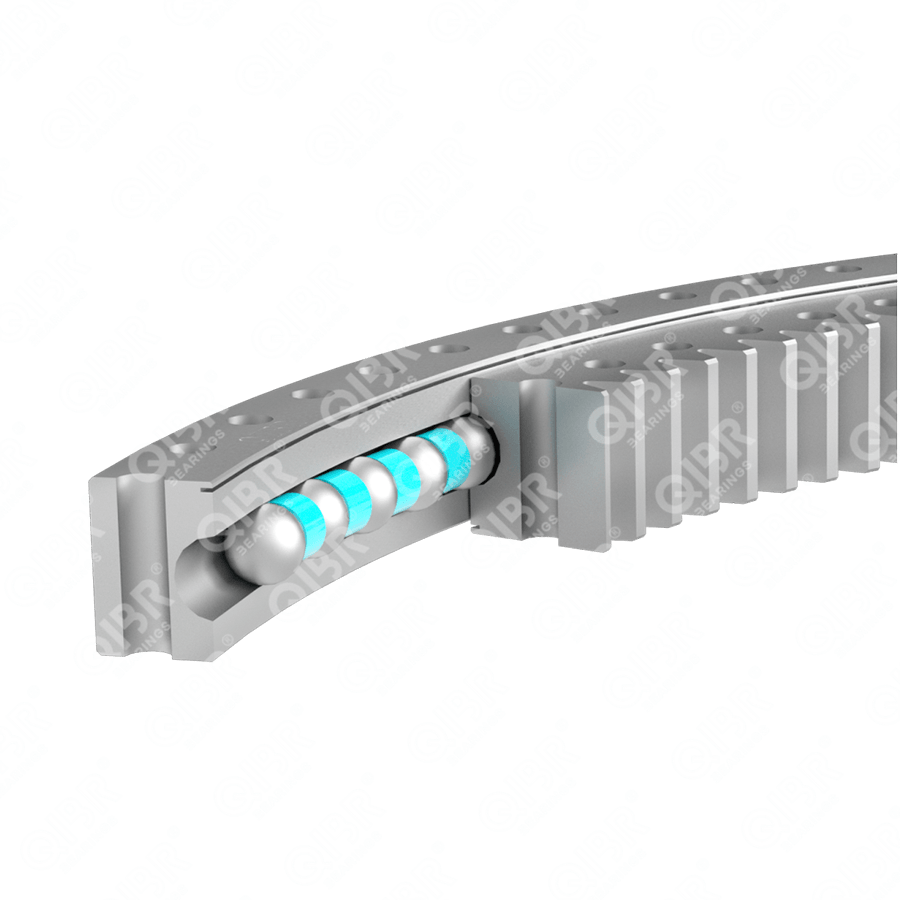

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - VSI 25 0855 N

Описание

QIBR - VSI 25 0855 N Поворотный Подшипник Преимущества и Применение

VSI 25 0855 N Поворотный Подшипник обладает высокой грузоподъемностью и высокой точностью.Inner diameter (di) - 710 mm,Outer diameter (Da) - 955 mm,Weight - 137 kg. Он подходит для высокоскоростных железных дорог, самолетов, морских буровых платформ, поворотных столов, штабелеров и регенераторов и т. д. Это наиболее широко используемый подшипник в рабочих условиях, требующих высокой точности.

QIBR - VSI 25 0855 N Поворотный Подшипник Характеристики

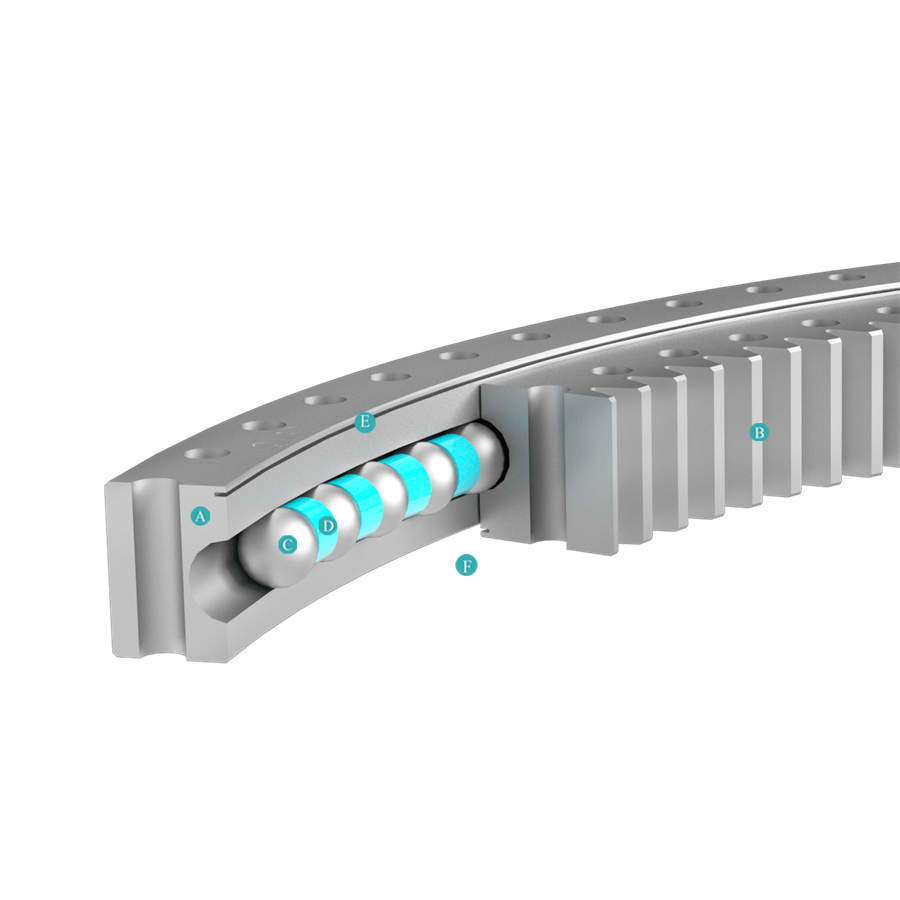

VSI 25 0855 N Поворотный Подшипник, простое обслуживание, низкие затраты на обслуживание, простая установка. VSI 25 0855 N Поворотный Подшипник, может выдерживать одновременно радиальную нагрузку, осевую нагрузку и опрокидывающий момент, подходит для механического оборудования с высокими требованиями к несущей способности.

VSI 25 0855 N Поворотный подшипник Особенности и преимущества

Компактная конструкция: Компактная конструкция позволяет устанавливать подшипники в условиях ограниченного пространства и имеет более широкий спектр применения.

Высокая грузоподъемность: Он может выдерживать осевые, радиальные и опрокидывающие моменты одновременно, подходит для тяжелых условий эксплуатации.

Превосходная точность: Поддерживают высокую точность в процессе эксплуатации и снижают количество ошибок при работе оборудования.

Высокая температура и износостойкость: Изготовлены из высокотемпературной подшипниковой стали, обладают хорошей износостойкостью и прочностью.

Применение: Широко используется в подъемных машинах, машиностроении, транспортном оборудовании, горном оборудовании, металлургическом оборудовании, медицинском оборудовании, судах, военных кораблях, радарах, ветрогенераторах и других областях.

QIBR - VSI 25 0855 N Оптимизация поворотных подшипников

Замена смазки: Замените смазку на другие смазки, такие как SFK, Mobil, Krupp и т.д., чтобы оптимизировать рабочие характеристики и условия использования подшипника.

Оптимизация покрытия: Нанесите другие покрытия, такие как цинкование или никелирование, чтобы повысить коррозионную стойкость и износостойкость и продлить срок службы в жестких условиях эксплуатации.

Оптимизация процесса: Оптимизация процесса производства подшипников, увеличение диапазона рабочих температур подшипников, повышение точности и стабильности подшипников.

Больше возможностей для настройки: QIBR может оптимизировать конструкцию подшипника в соответствии с чертежами заказчика или требованиями оборудования, чтобы удовлетворить потребности оборудования.

QIBR - VSI 25 0855 N Контроль качества поворотных подшипников

Измерение размеров: Использование различных профессиональных высокоточных приборов для измерения различных размеров подшипника, с высочайшей точностью до 0,01 мм.

Точность вращения: Используйте циферблатный индикатор для измерения небольших дефектов или отклонений на поверхности подшипника, с точностью измерения до 0,01 мм.

Измерение твердости: Используйте твердомер Лееба для измерения твердости поверхности подшипника, с точностью измерения ±6HLD.

Металлографический анализ: Используйте профессиональный металлографический микроскоп для анализа внутренней металлографической структуры металла.

Геометрический допуск: Используйте измеритель круглости для измерения геометрии и относительного положения подшипника.

Мониторинг шума: Используйте виброметр для контроля вибрации во время работы и получения данных о шуме.

Особенности и преимущества

Стандартная серия 20. Внутренние зубья шестерни, выбираемый внутренний зазор, герметичные, смазочный ниппель по окружности кольца без зубьев.

Скачать