QKR 26 B

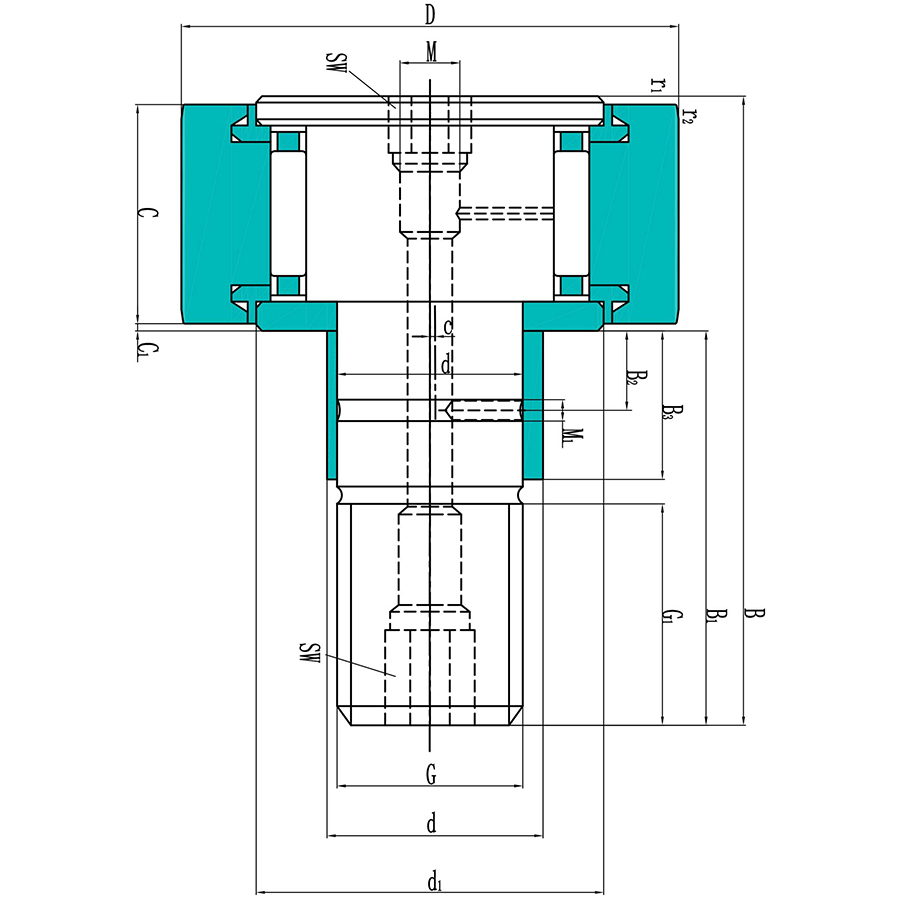

- Наружный диаметр (D)

- 26 mm

- Диаметр крепления (d)

- 10 mm

- Общая длина (B)

- 36 mm

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - QKR 26 B

Описание

QKR 26 B Cam Followers Features and Advantages

High load capacity: The radial load capacity is particularly high, allowing it to withstand axial loads caused by misalignment or tilt.

Mitigation of Uneven Loads: The spherical outer ring bearings can alleviate uneven loads resulting from installation errors.

Wear Resistance and Low Friction: They reduce wear and sliding friction, thereby extending service life and improving operational efficiency.

Reduced Deformation and Stress: The thick outer ring minimizes deformation and bending stress under high loads, ensuring the stability and reliability of the bearing.

Application: Widely used in fields such as automation machinery, CNC machine tools, industrial robots, automotive industry, material handling equipment, construction machinery, and agricultural equipment.

QIBR - QKR 26 B Cam Followers Optimization

High-Performance Materials: Bearing materials are replaced based on different working conditions, such as GCr15, 100Cr6, and bearing steel.

Surface Heat Treatment: Heat treatments, such as nitriding and carburizing, are used to enhance the surface hardness and wear resistance of the bearings.

Surface Coatings: Surface coatings are applied according to customer requirements, such as chrome plating, nickel plating, or PTFE coatings.

More customization: QIBR can design and optimize bearings based on customer drawings and operational requirements.

QIBR - QKR 26 B Cam Followers quality control

Dimension measurement: Various high-precision instruments are used to measure multiple dimensions of the bearings, with maximum precision reaching 0.001mm.

Rotation accuracy: A micrometer is used to measure small defects or deviations on the bearing surface, achieving measurement precision of 0.001mm.

Hardness measurement: Hardness is measured using a hardness tester, with a precision of ±0.5HRC.

Metallographic analysis: A professional metallographic microscope is used to analyze the internal metallographic structure of the metal.

Geometric Tolerance: A profile projector is used to measure the geometric shape and relative position of the bearings.

Noise monitoring: Vibration meters monitor the vibration during operation to obtain noise data.

Raw material control: Steel and parts are purchased from suppliers certified by ISO 14001 to ensure product stability and promote sustainable development.

Особенности и преимущества

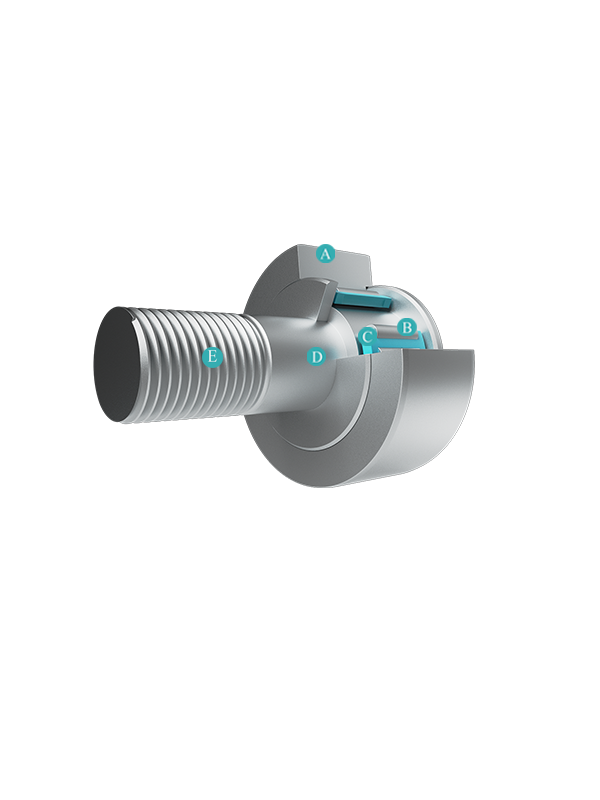

Опорные ролики, также известный как следящий кулачок, - это специализированный тип роликового или игольчатого подшипника, разработанный для следования профилю лепестков кулачка. Последователи кулачков имеют огромное количество различных конфигураций, однако наиболее определяющей характеристикой является способ их крепления к сопрягаемой детали: в последователях кулачков со шпилькой используется шпилька, а в последователях с ярмом - отверстие посередине.

Скачать