QUCF206

- Наименование подшипника

- UC206

- Модель корпуса

- F206

- Вес

- 1.02 kg

Мы предложим вам самое подходящее решение.

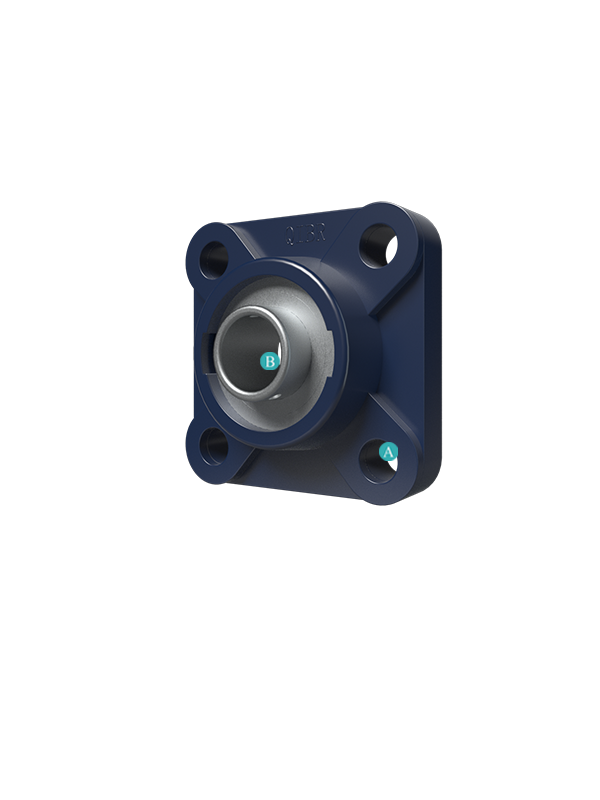

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - QUCF206

Описание

QUCF206 Bearing Unit Product Features and Advantages

Self-aligning ability: Compensates for installation errors, adapts to slight eccentricity of the shaft, and reduces wear caused by misalignment.

High load-bearing capacity: Able to withstand large radial and axial loads, suitable for heavy-load and high-strength applications.

Reduce friction and energy consumption: Through QIBR optimized design, friction is reduced, mechanical efficiency is improved, and energy consumption is reduced.

Economical: High durability and low maintenance requirements, which can significantly reduce operating costs in long-term use.

Application: It has a wide range of applications in agricultural equipment, material handling equipment, the automotive industry, mining and construction, the food and beverage industry, and industrial machinery.

QIBR - QUCF206 Bearing Unit Optimization

Grease replacement: Select grease according to the working needs of the bearing unit, such as SKF, FAG, NSK, NTN, Klüber, etc.

Surface treatment: Optimize the surface of the bearing unit, and use surface treatment technologies such as nitriding treatment, ceramic coating, and Dacromet coating according to customer needs to improve the wear resistance and corrosion resistance of the surface.

Sealing structure: The sealing structure can be selected according to the working environment of the bearing unit, such as FKM/fluorine rubber sealing for high temperature resistance, hydrogenated nitrile butadiene rubber (HNBR) sealing for low temperature resistance, and polyetheretherketone (PEEK) sealing for chemical resistance, ensuring that it can be used under different working conditions. Excellent temperature resistance, oil resistance and chemical resistance.

More customization: QIBR can design and optimize the bearing unit according to the customer's drawings and bearing unit working condition requirements.

QIBR - QUCF206 Bearing Unit Quality Control

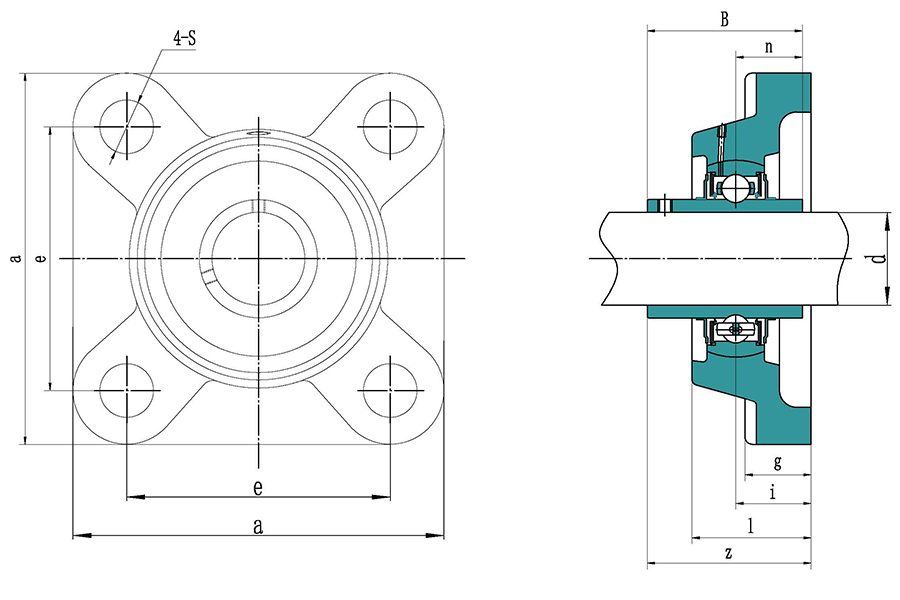

Dimension measurement: Using a variety of professional high-precision instruments to measure multiple dimensions of the bearing unit, the highest accuracy can reach 0.001mm.

Rotation accuracy: Use a dial indicator to measure small flaws or deviations on the surface of the bearing unit, and the measurement accuracy can reach 0.001mm.

Hardness measurement: Measure the surface hardness of the bearing unit through a hardness tester, and the measurement accuracy can reach ±0.5HRC.

Metallographic analysis: Analyze the internal metallographic structure of the metal through a professional metallographic microscope.

Geometric tolerance: Use a profilometer to measure the bearing unit geometry and relative position.

Noise monitoring: Use a vibration meter to monitor the vibration during operation and obtain noise data.

Raw material control: Purchasing steel and parts from ISO 14001 certified suppliers ensures product stability while promoting sustainable development.

Особенности и преимущества

Подшипниковый узел состоит из наружного сферического подшипника и седла. Простая конструкция позволяет подшипниковому узлу самостоятельно регулироваться и компенсировать ошибки при установке. Двойное уплотнение эффективно предотвращает утечку смазки и попадание загрязнений. Для удовлетворения различных потребностей предлагаются различные модели, такие как квадратные, круглые и ромбовидные посадочные места. Эти характеристики и преимущества делают подшипниковый узел с седлом идеальным выбором для различных промышленных применений.

Скачать