Q16393001

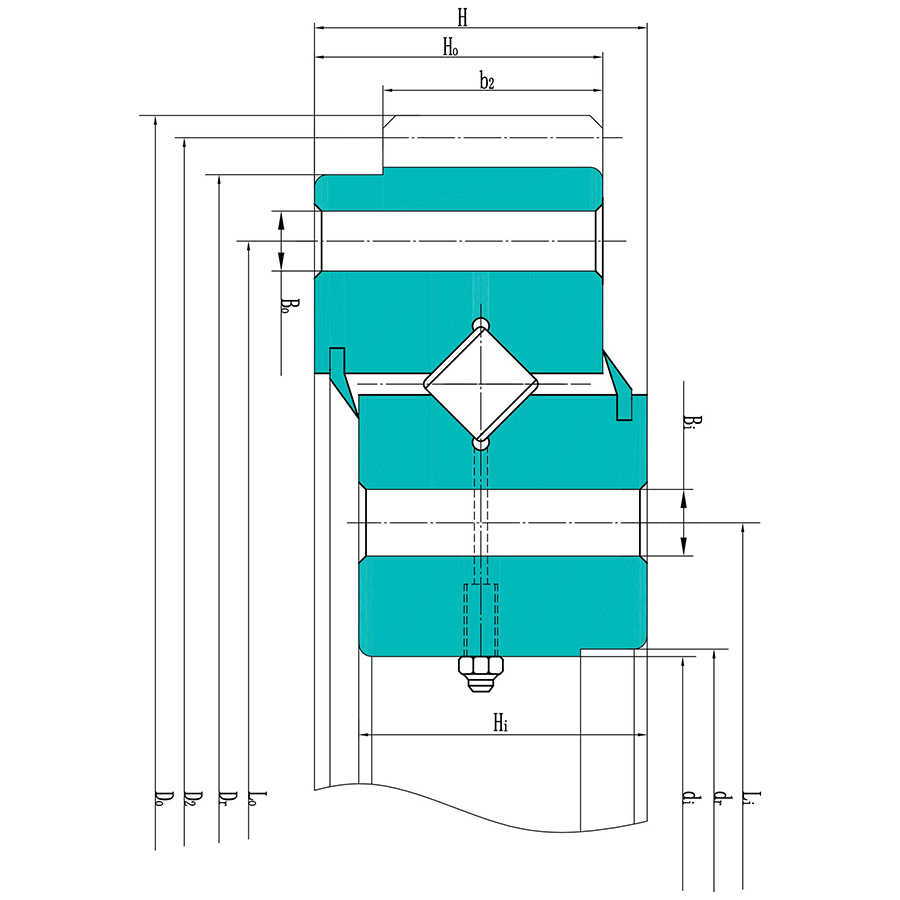

- Наружный диаметр (Do)

- 209.843 inch

- Внутренний диаметр (di)

- 188.583 inch

- Общая высота (H)

- 7.047 inch

Мы предложим вам самое подходящее решение.

Изображения могут отличаться от продукта. Подробнее см. технические характеристики.

Характеристики

Seris - Q16393001

Описание

Q16393001 Slewing Bearing Features and Advantages

Compact design: Compact structure, it can be installed in space-constrained environments, and has a wider range of applications.

High load capacity: It can withstand axial, radial and overturning moments at the same time, suitable for heavy-duty applications.

Superior precision: Maintain high precision during use and reduce errors in equipment operation.

High temperature and wear resistance: Made of high-temperature bearing steel, with good wear resistance and strength.

Application: Widely used in lifting machinery, engineering machinery, transportation machinery, mining machinery, metallurgical machinery, medical equipment, ships, warships, radar, wind power generation and other fields.

QIBR - Q16393001 Slewing Bearing Optimization

Grease replacement: Replace grease with other greases such as SFK, Mobil, Krupp, etc. to optimize the working performance and use conditions of the bearing.

Coating optimization: Provide other coatings such as zinc plating or nickel plating to enhance corrosion resistance and wear resistance and extend its service life in harsh environments.

Process optimization: Optimize the bearing production process, increase the bearing operating temperature range, and improve the bearing accuracy and stability.

More customization: QIBR can optimize the bearing structure design according to customers’ drawings or equipment requirements to meet equipment needs.

QIBR - Q16393001 Slewing support bearing quality control

Dimension measurement: Use a variety of professional high-precision instruments to measure multiple dimensions of the bearing, with the highest accuracy up to 0.01mm.

Rotation accuracy: Use a dial indicator to measure small flaws or deviations on the bearing surface, with a measurement accuracy of up to 0.01mm.

Hardness measurement: Use a Leeb hardness tester to measure the bearing surface hardness, with a measurement accuracy of ±6HLD.

Metallographic analysis: Use a professional metallographic microscope to analyze the internal metallographic structure of the metal.

Geometric tolerance: Use a roundness meter to measure the bearing geometry and relative position.

Noise monitoring: Use a vibration meter to monitor the vibration during operation and obtain noise data.

Особенности и преимущества

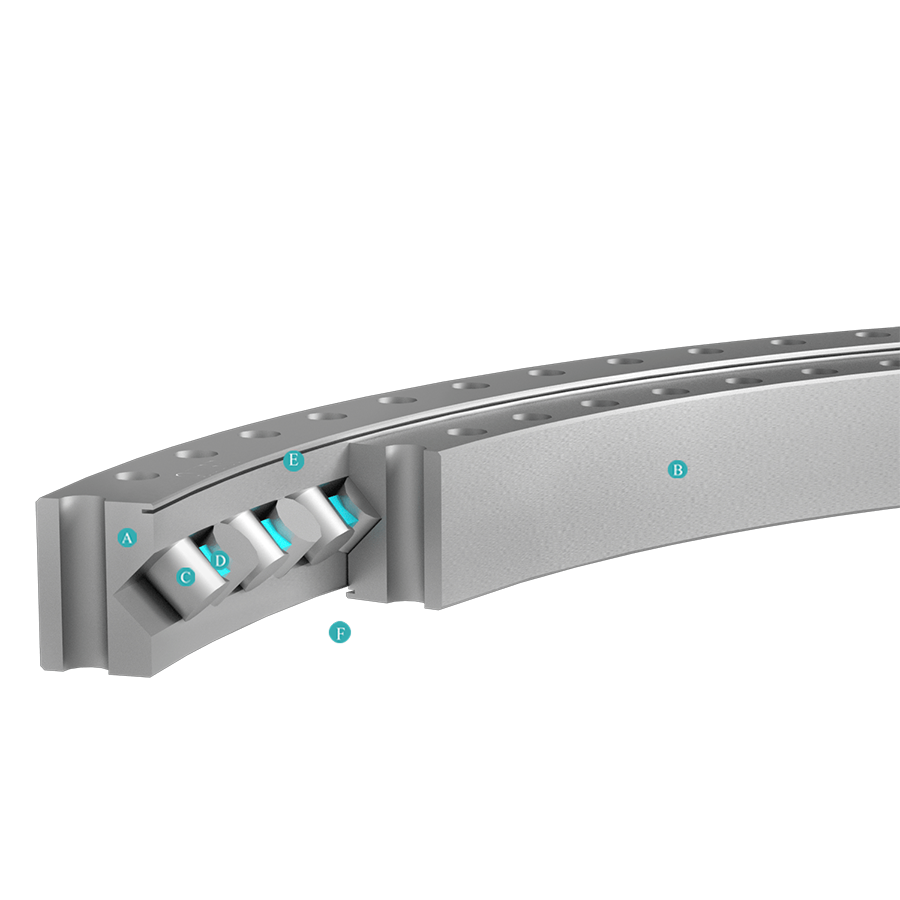

The slewing bearing consists of five essential components: the inner ring, which rotates; the outer ring, which remains stationary; rolling elements that facilitate movement; spacers for even distribution; and seals that protect against contaminants and retain lubrication.

Скачать